Light guiding plate, backlight module and display device

A technology of backlight module and light guide plate, which is applied in lighting devices, fixed lighting devices, optics and other directions to achieve the effects of reducing distance, excellent optical performance and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

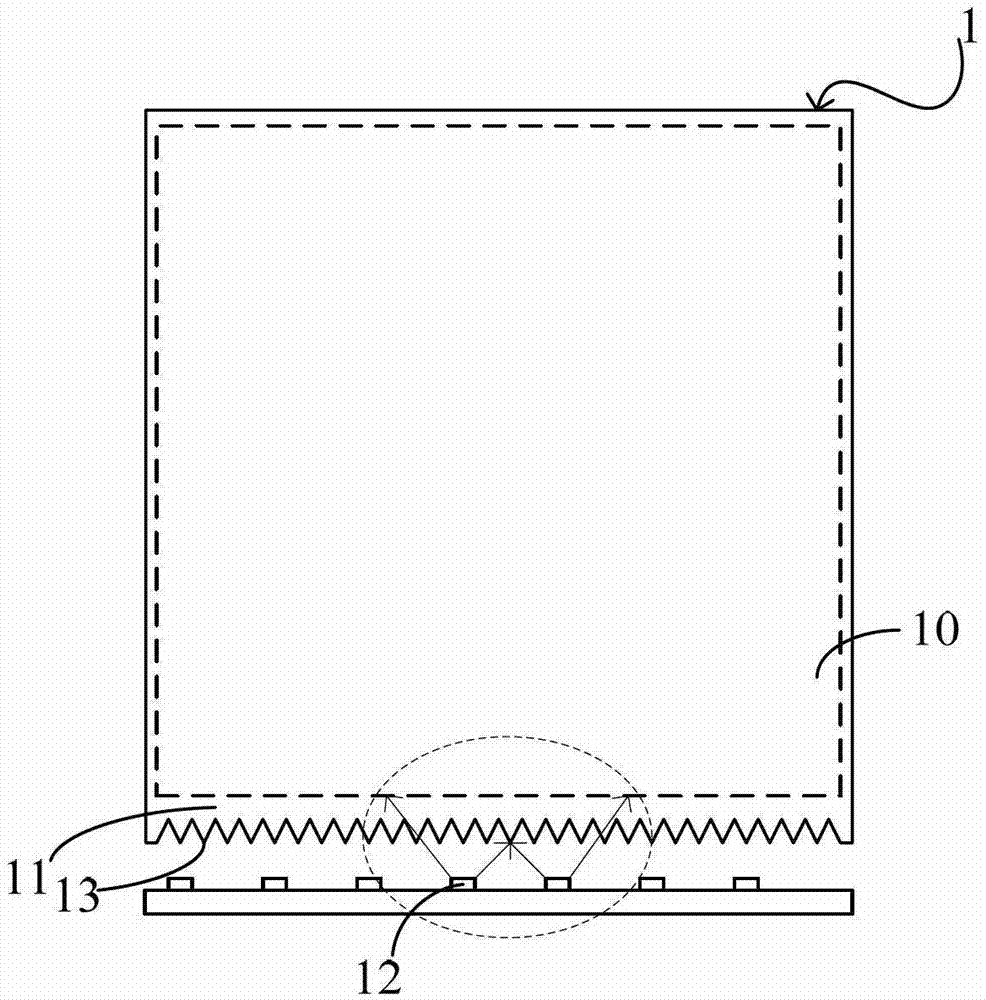

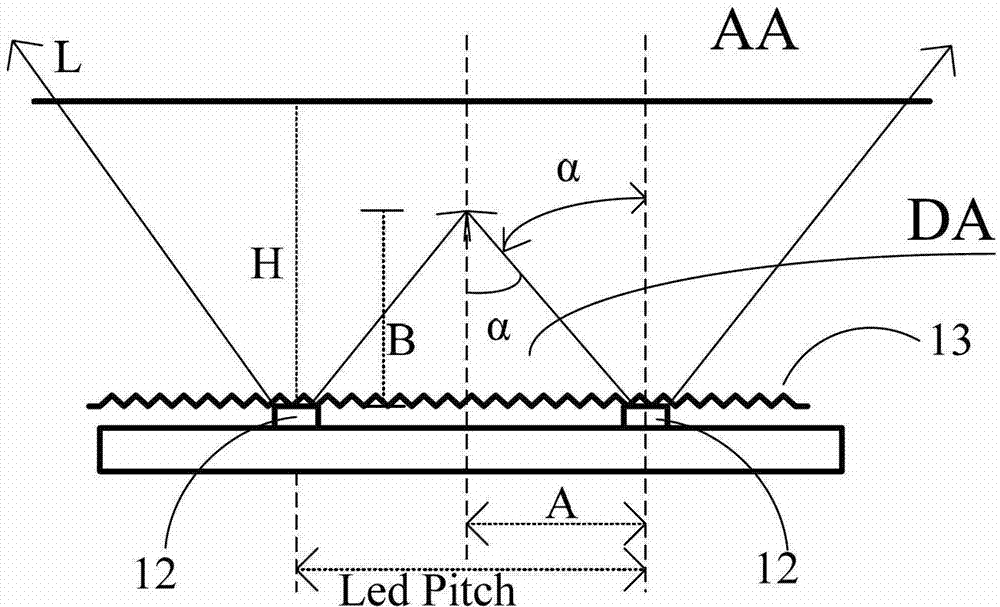

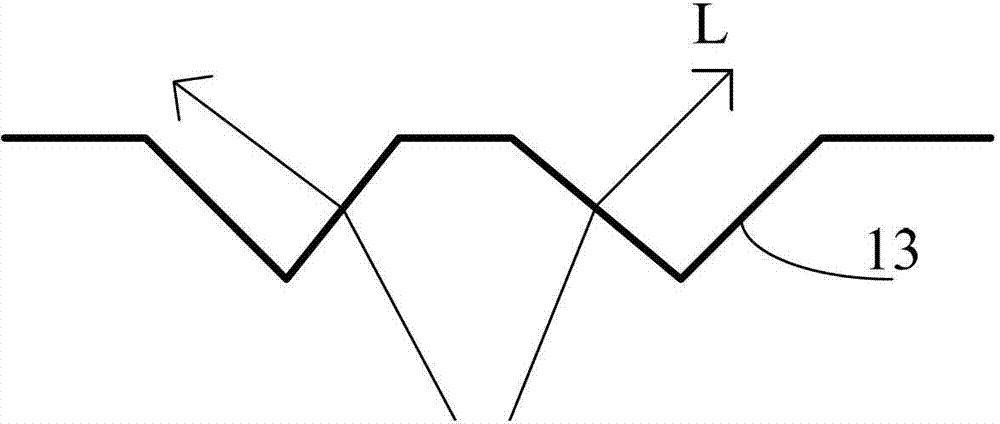

[0032] like Figure 2a , Figure 2b As shown, the present invention discloses a structure of a light guide plate, the light guide plate is in the shape of a flat plate, and is used in a side backlight module. The light guide plate 1 mainly includes a light incident surface 11, the light incident surface 11 is made of the same dielectric material polycarbonate, a light exit surface 10 connected to the light incident surface 11, and two concave recesses are arranged on the light incident surface 11. The sawtooth structures on the light-incoming surface are respectively the first sawtooth structure 14 and the second sawtooth structure 15, and the two sawtooth structures are perpendicular to the light-emitting surface 10. Each unit structure of the sawtooth structure is a continuous structure with equal intervals. The shape is triangular. The sawtooth structure is set on the light incident surface by mechanical overmolding. Specifically, the first sawtooth structure 14 is provi...

Embodiment 2

[0039] On the basis of the first embodiment disclosed in the present invention, the present invention discloses another structure of the light guide plate, such as Figure 3a , Figure 3b As shown, it is a schematic diagram of the light guide plate. The light guide plate is flat and used in the side backlight module. The light guide plate 1 mainly includes a light incident surface 11, the light incident surface 11 is made of two media with different refractive indices, the medium at the front end of the light incident surface is polycarbonate M1, and the medium of other parts of the light incident surface is polymethacrylic acid Methyl ester M2. The light-emitting surface 10 connected to the light-incident surface 11 and the light-incident surface 11 are provided with two sawtooth structures recessed into the light-incidence surface, which are respectively the first sawtooth structure 14 and the second sawtooth structure 15, and the two sawtooth structures are vertical On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com