Backlight illumination structure based on double-sided light-dimming light guide plate and manufacturing method of backlight illumination structure

A technology for backlight illumination and light guide plate, applied in the direction of plane/plate light guide, light guide, light guide of lighting system, etc., can solve the problems of unpackaged quantum dots and complex structure, so as to improve market competitiveness, simplify device structure, The effect of reducing thickness and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

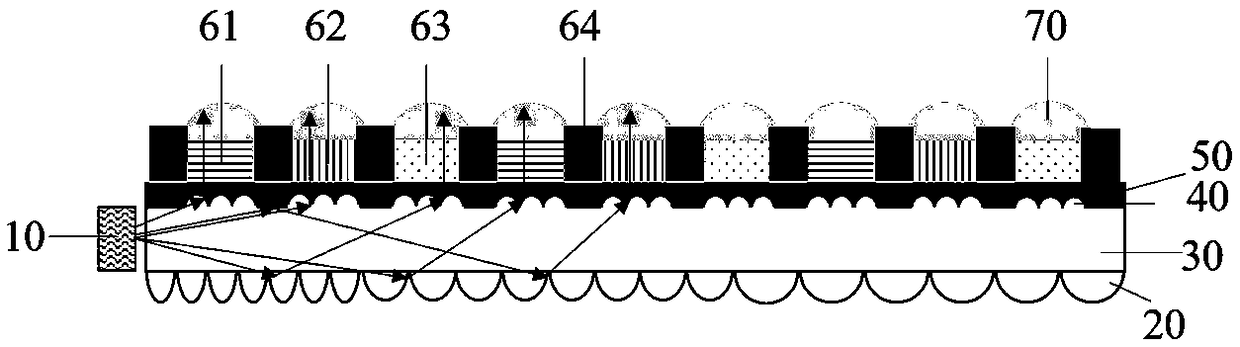

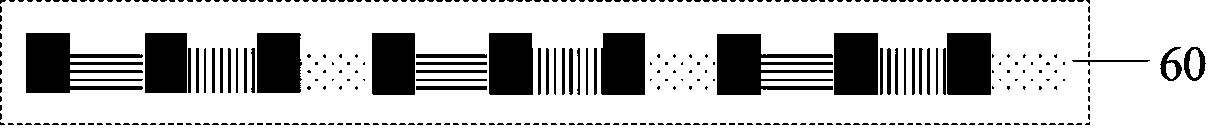

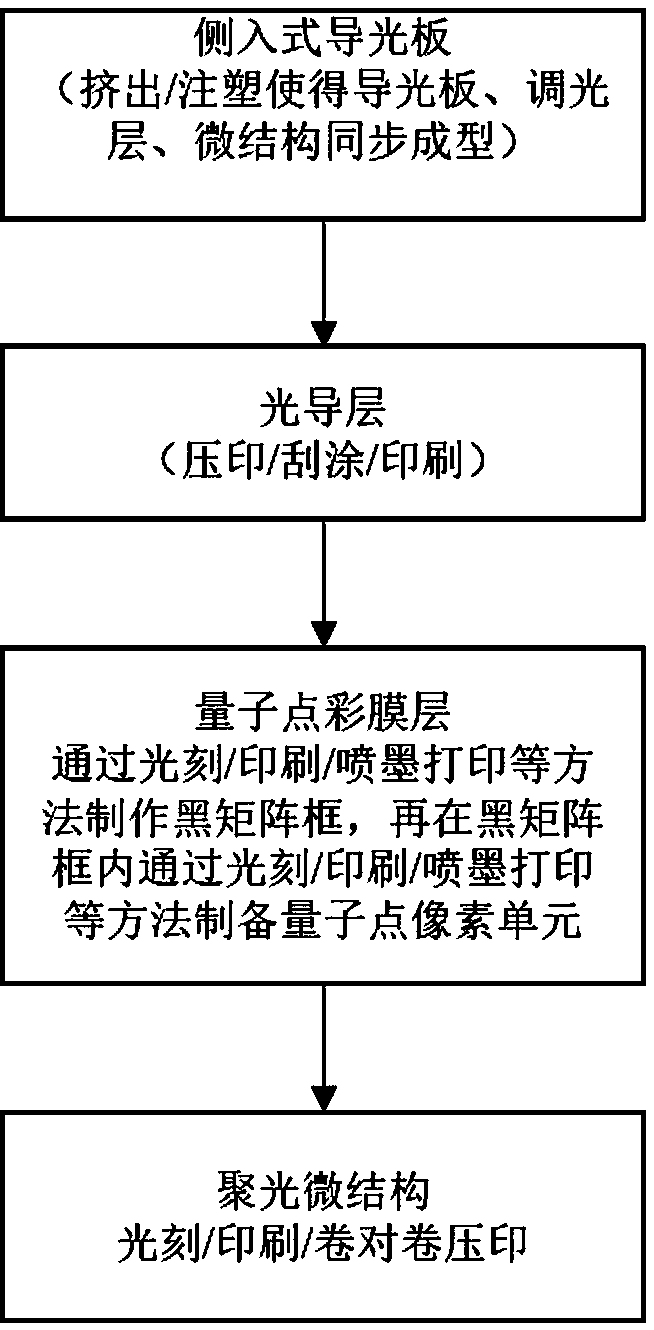

[0036] Such as figure 1 As shown, 10 is a blue LED dot matrix backlight, the light source interval is 5 mm, and the light source wavelength is 365 nm, 20 is a scattering microstructure, 30 is a side-entry light guide plate, 40 is a collimating microstructure, and 50 is a light guide layer of a substrate. 60 is a quantum dot color film layer, 61 and 62 are quantum dot red and green pixel units respectively, 63 is an empty pixel unit, 64 is a black matrix, and 70 is a convex lens light-condensing microstructure. The scattering microstructure on the lower surface of the light guide plate and the collimating microstructure on the upper surface are designed, and the radius of curvature of the scattering microstructure near the light incident side is 10e -5 m, the radius of curvature away from the light-incident side becomes larger and larger in a certain law; the radius of curvature of the collimated microstructure is 5e -5 m, and make positioning marks for precise alignment with ...

Embodiment 2

[0039] Such as Figure 4As shown, 10 is a blue LED dot matrix backlight, the light source interval is 5 mm, and the light source wavelength is 365 nm, 20 is a scattering microstructure, 30 is a side-entry light guide plate, 40 is a collimating microstructure, and 50 is a light guide layer of a substrate. 60 is a quantum dot color film layer, 61 and 62 are quantum dot red and green pixel units respectively, 63 is an empty pixel unit, 64 is a black matrix, and 71 is a convex lens light-condensing microstructure. The scattering microstructure on the lower surface of the light guide plate and the collimating microstructure on the upper surface are designed, and the radius of curvature of the scattering microstructure near the light incident side is 12e -5 m, the radius of curvature away from the light-incident side becomes larger and larger according to a certain rule; the curvature radius of the collimated microstructure is 6e -5 m, and make positioning marks for precise alignme...

Embodiment 3

[0041] Such as Figure 5 As shown, 10 is a blue LED dot matrix backlight, the light source interval is 5 mm, and the light source wavelength is 365 nm, 20 is a scattering microstructure, 30 is a side-entry light guide plate, 40 is a collimating microstructure, and 50 is a light guide layer of a substrate. 65 is a quantum dot light conversion film layer, 72 is a convex lens light-condensing microstructure, 81, 82 and 83 are red, green and blue three primary color filters, and 84 is a black matrix. The scattering microstructure on the lower surface of the light guide plate and the collimating microstructure on the upper surface are designed, and the radius of curvature of the scattering microstructure near the light incident side is 12e -5 m, the radius of curvature away from the light-incident side becomes larger and smaller in a certain order; the radius of curvature of the collimated microstructure is 6e -5 m, and make positioning marks for precise alignment with the subsequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com