Back light system

A technology of backlight system and light source, applied in the field of backlight system, can solve the problems of difficulty in implementation and poor uniformity of light output, and achieve the effects of increasing viewing angle, enhancing brightness and uniform light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

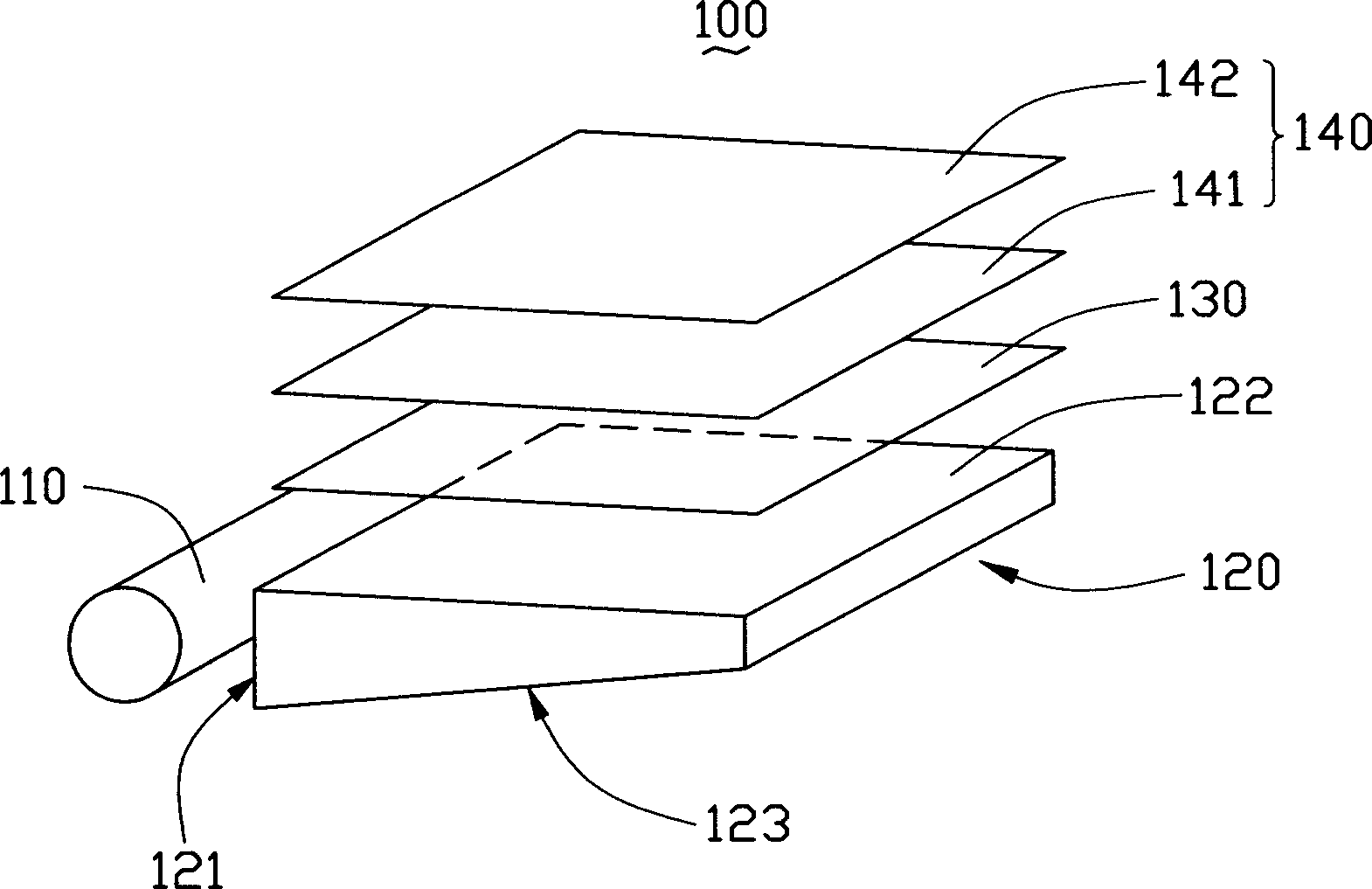

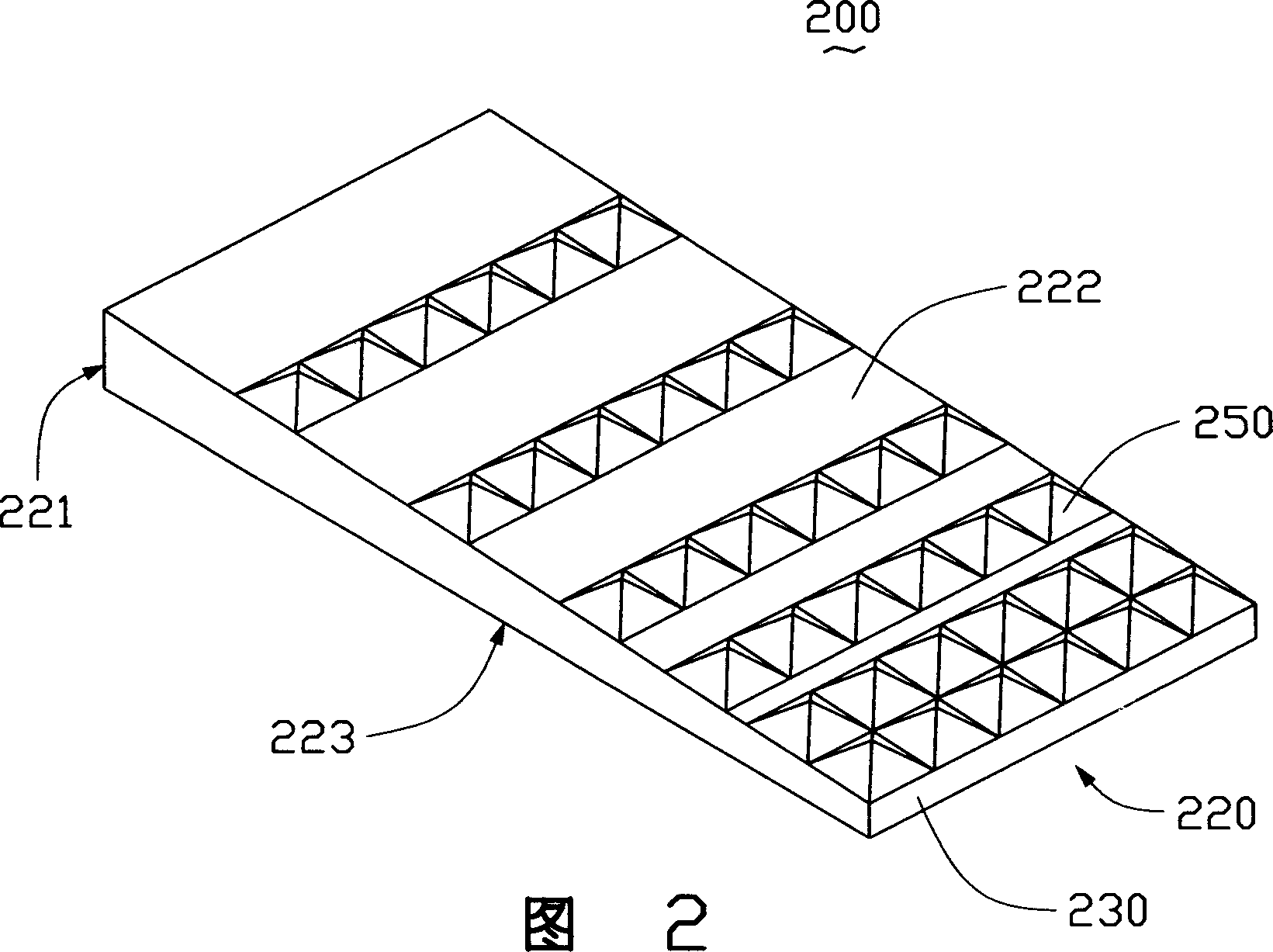

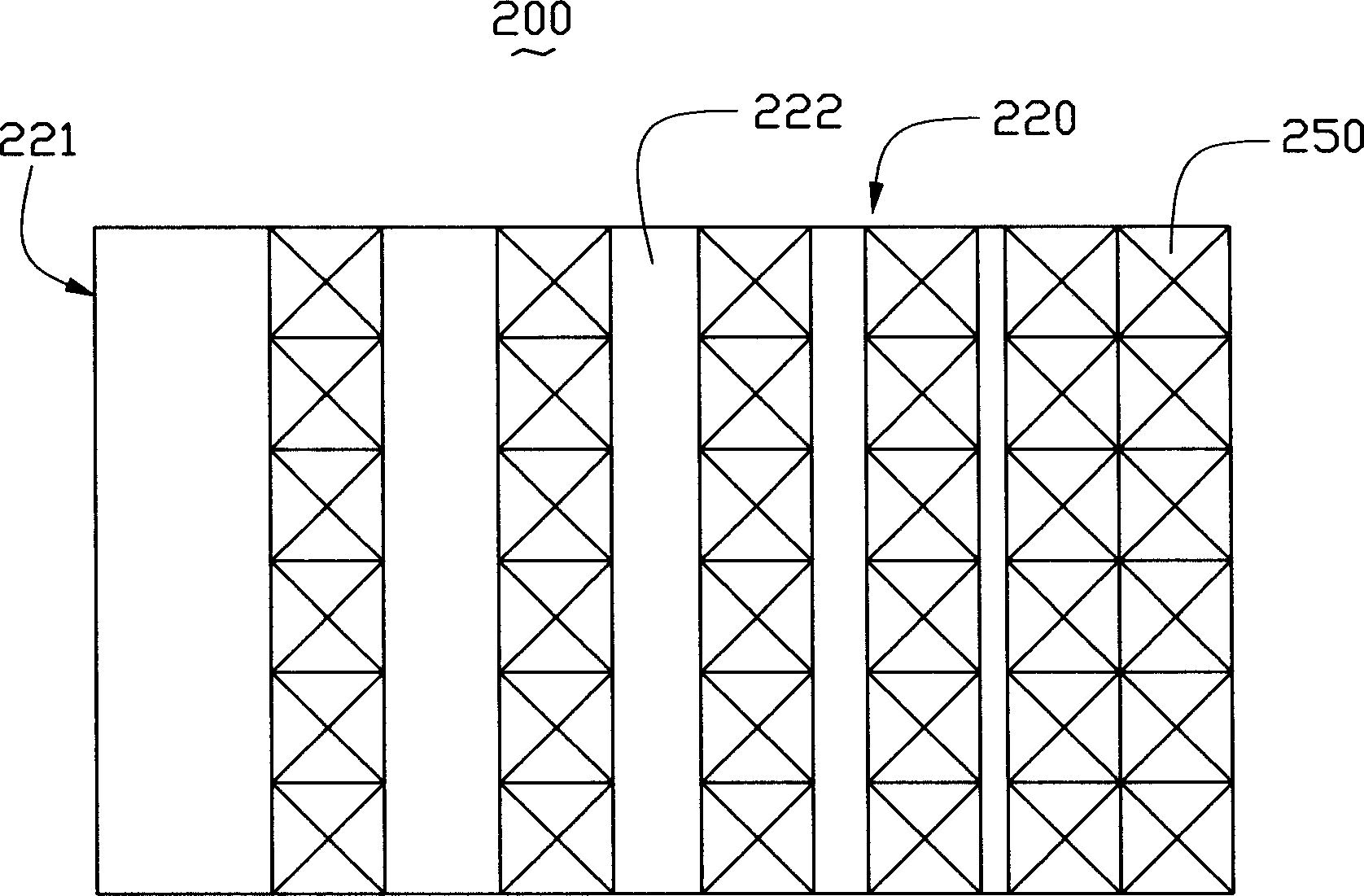

[0017] Figure 4 It is a perspective view of the first embodiment of the backlight system of the present invention. The backlight system 30 includes a light source 310 and a light guide plate 300. The light guide plate 300 is an integrally formed cuboid structure, and its material can be polyethylene, polycarbonate and the like. The light guide plate includes an incident surface 321, an exit surface 322 and a bottom surface 323, wherein the incident surface 321 receives the light beam emitted by the side light source 310 and guides the light beam into the light guide plate 300, and the bottom surface 323 guides the light beam into the light guide plate 300. The light beam is reflected and scattered to form a scattered light beam uniformly diverging in all directions. The output surface 322 guides the uniformly divergent light beam out of the light guide plate 300 and guides it to a liquid crystal display panel (not shown). The light source 310 is arranged on the light guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com