Processing method of zipper cloth strap

A processing method and cloth tape technology, applied in dyeing, textile material processing, weaving, etc., can solve the problems of long weaving time and low efficiency, achieve pure color, improve efficiency, and facilitate application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

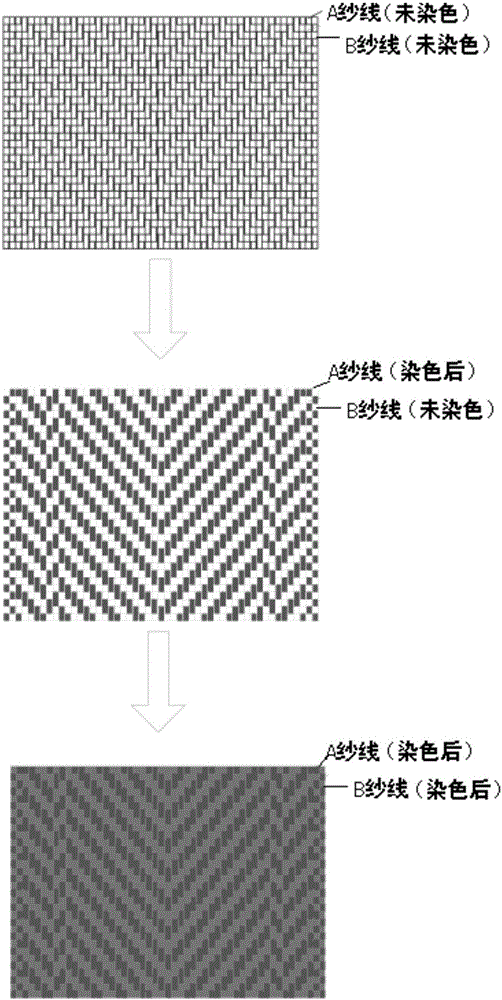

[0062]1) Provide the zipper tape to be dyed; the zipper tape to be dyed is woven from A yarn and B yarn, the A yarn is 300D polyester yarn (DTY), and the B yarn is 300D cationic polyester yarn (Xianglu Chemical Fiber Co., Ltd., 333detx / 72f), the blending ratio of cationic yarn and polyester yarn is 60%: 40%; the grammage of the zipper tape to be dyed is 7.7g / m, and the weft density is 16.5 shuttles / cm, the warp density is 32 pieces / cm;

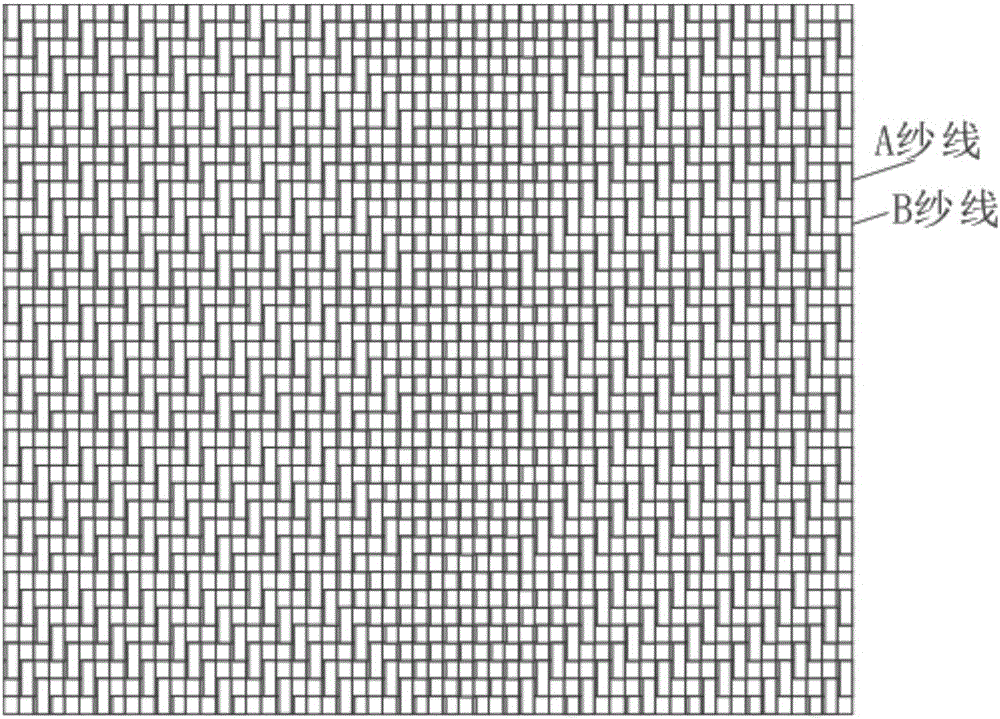

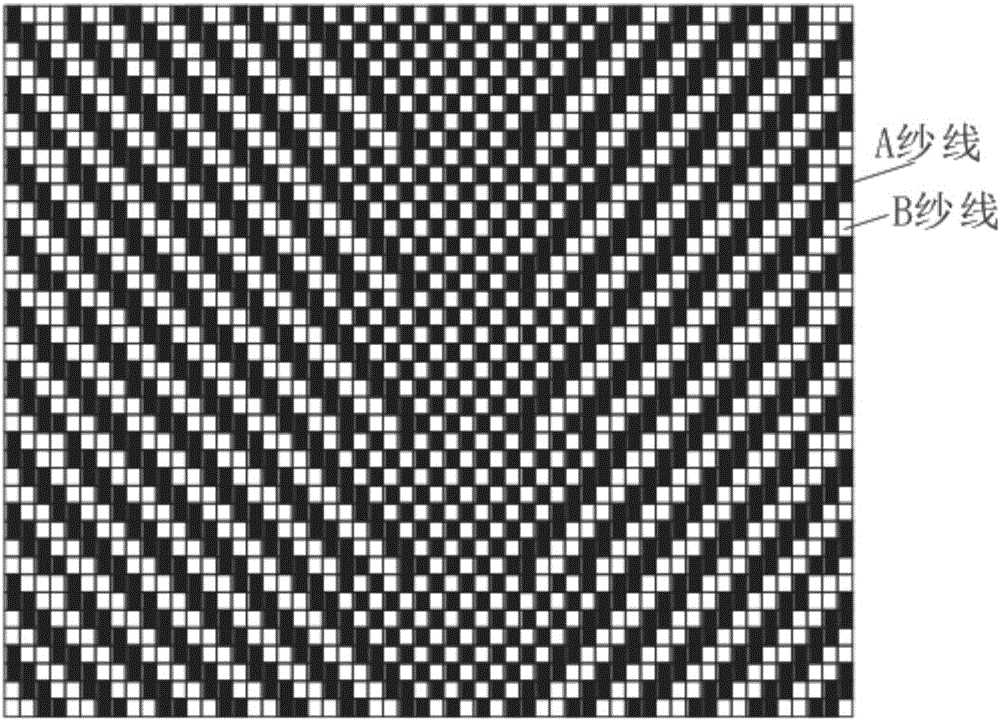

[0063] The zipper tape to be dyed has a herringbone structure, and its organizational structure is shown in Figure 4 , Figure 4 It is the organizational structure and weaving diagram of the zipper tape to be dyed in Example 1 of the present invention. The organizational structure of the zipper tape is that the 54 warp threads are single-thread 2-up and 2-down structure, and the last 2 ends are single-thread 1-up and 1-down structure.

[0064] 2) Carry out high-temperature and high-pressure dyeing of the zipper tape to be dyed with disper...

Embodiment 2

[0071] 1) Provide the zipper tape to be dyed, the zipper tape to be dyed is woven from A yarn and B yarn, the A yarn is 300D polyester yarn (DTY), and the B yarn is 300D cationic polyester yarn (Xianglu Chemical Fiber Co., Ltd., 333detx / 72f), the blending ratio of cationic yarn and polyester yarn is 60%: 40%; the grammage of the zipper tape to be dyed is 7.7g / m, and the weft density is 14.9 shuttles / cm, the warp density is 34.3 strands / cm;

[0072] The zipper tape to be dyed has a twill structure, and its organizational structure is shown in Figure 6 , Figure 6 It is the organizational structure and weaving diagram of the zipper tape to be dyed in Example 2 of the present invention. The organizational structure of the zipper tape is that the total number of warp threads is 60, and the order of every 4 warp threads is 2 single threads, 2 upper and 2 lower, and 2 single threads, 1 upper and 1 lower.

[0073] 2) Carry out high temperature and high pressure dyeing of the zip...

Embodiment 3

[0080] 1) Provide the zipper cloth tape to be dyed, the zipper cloth tape to be dyed is woven by A yarn and B yarn, the A yarn is 300D polyester yarn, and the B yarn is 300D cotton yarn; the zipper cloth to be dyed The specifications of the belt are: 45×45 counts, 65 / 35 polyester / cotton fine fabric;

[0081] The zipper tape to be dyed has a plain weave structure, its organizational structure is referring to Fig. 7, and Fig. 7 is the organizational structure and weaving diagram of the zipper tape to be dyed in Example 3 of the present invention; 56 warps, each 4 warp threads are single-thread 2-up and 2-down structure, and the last 2 warp threads are single-thread 1-up and 1-down structure.

[0082] 2) hot-melt dyeing the zipper tape to be dyed with disperse dyes to obtain a semi-finished product of zipper tape dyeing; wherein, the dye solution formula for disperse dyeing includes:

[0083] Disperse blue 2BLN 1.5g / L;

[0084] Wetting agent JFC lmL / L;

[0085] Diffusion agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com