Steam heating device for cloth roller of beam dyeing machine

A technology of steam heating device and cloth rolling roller, which is applied in textile processing machine accessories, equipment configuration for processing textile materials, liquid/gas/steam open-width fabric processing, etc. It can solve the problems of head and tail color difference, and achieve the elimination of head and tail color difference , to solve the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

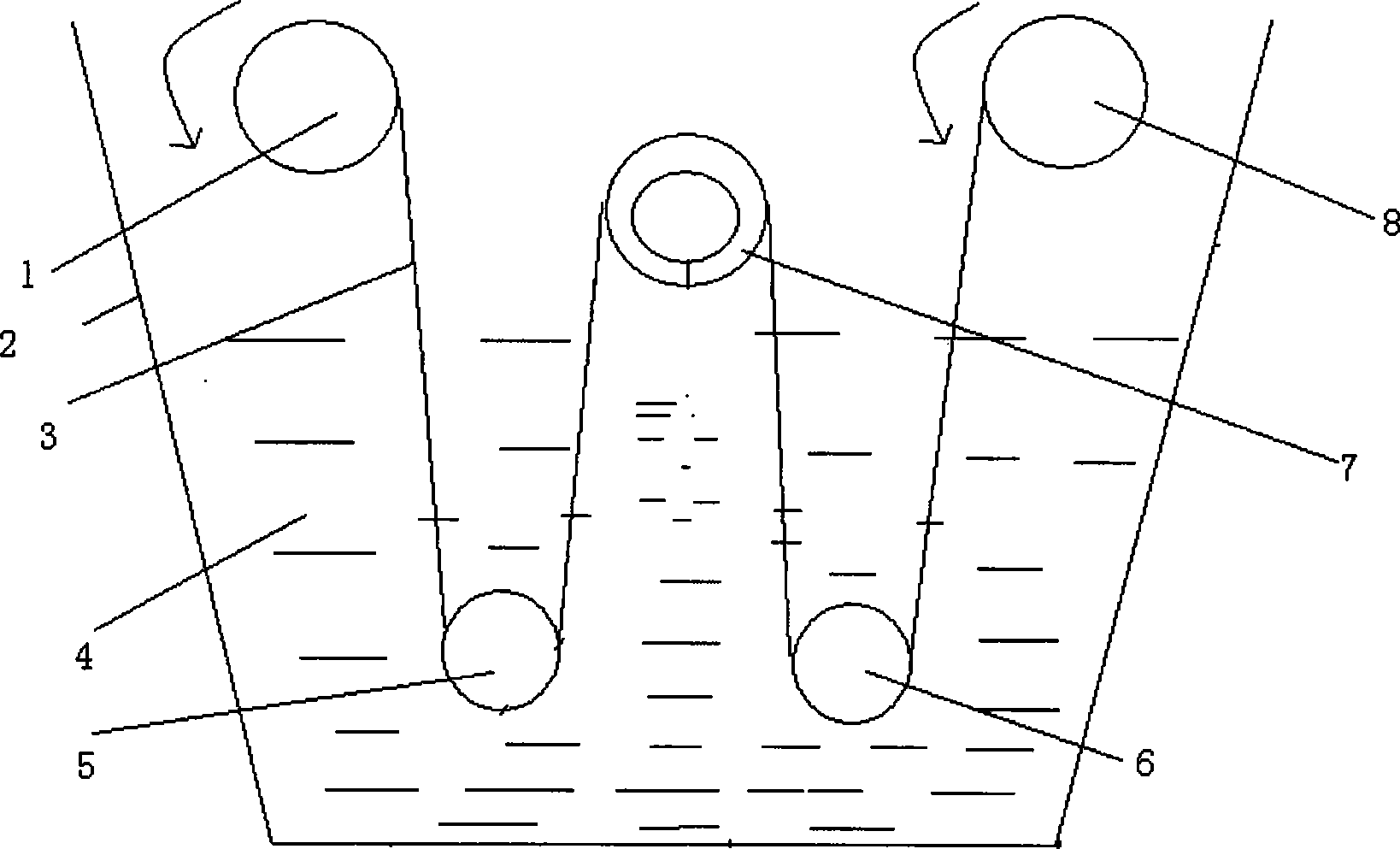

[0010] figure 1 It is a schematic diagram of the dyeing structure of a jigger in the prior art. The jigger includes a housing 2 in which the dye solution is located. It also includes a first cloth roll 1 and a second cloth roll 8 located at the upper end of the liquid surface. The first lower roller 5 and the second lower roller 6 inside the dye liquor are located between the first lower roller 5 and the second lower roller 6 and above the first lower roller 5 and the second lower roller 6 The force measuring roller 7, the pre-processed fabric 3 is rolled onto the second cloth roll 8, and then the cloth head passes through the second lower roller 6, the force measuring roller 7, and the first lower roller 5 to the first cloth roller 1 on.

[0011] When dyeing starts, the first cloth roll 1 rotates counterclockwise, and the first lower roller 5 and the second lower roller 6 are driven by the cloth. The force measuring roller 7 and the second cloth roller 8 rotate to make the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com