Jig dyeing cloth linear velocity detection device

A technology of speed detection and cloth line, which is applied in the processing of textile material equipment configuration, textile material processing, textile and papermaking, etc., can solve problems such as color difference, achieve stable work, improve dyeing quality, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

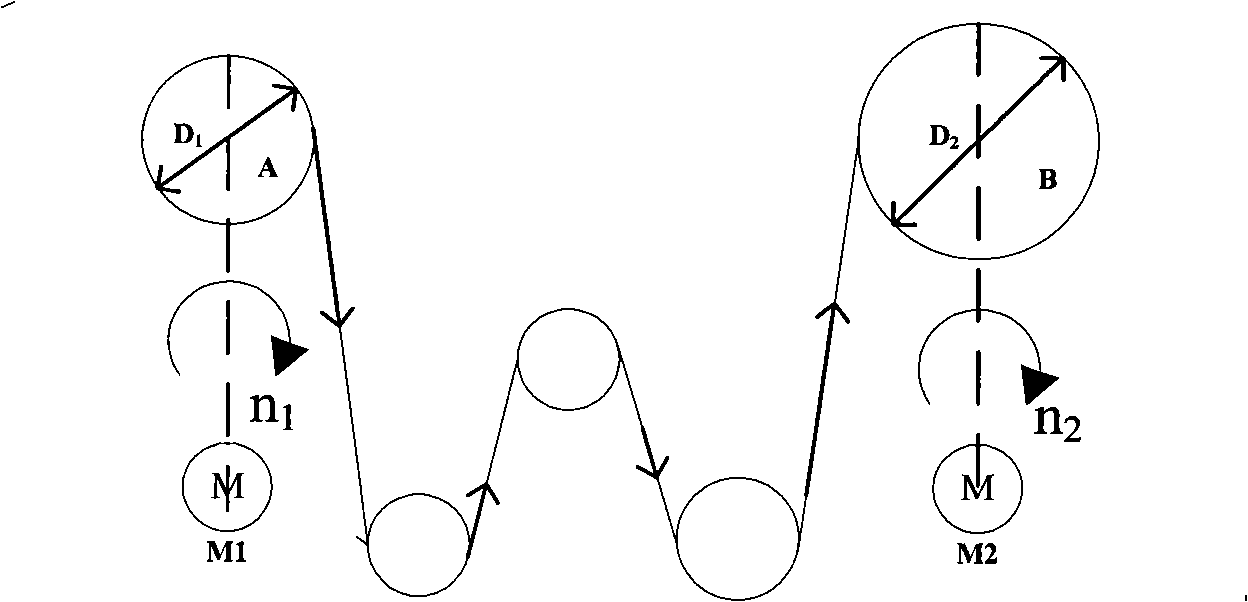

[0012] Further illustrate the present invention below in conjunction with accompanying drawing.

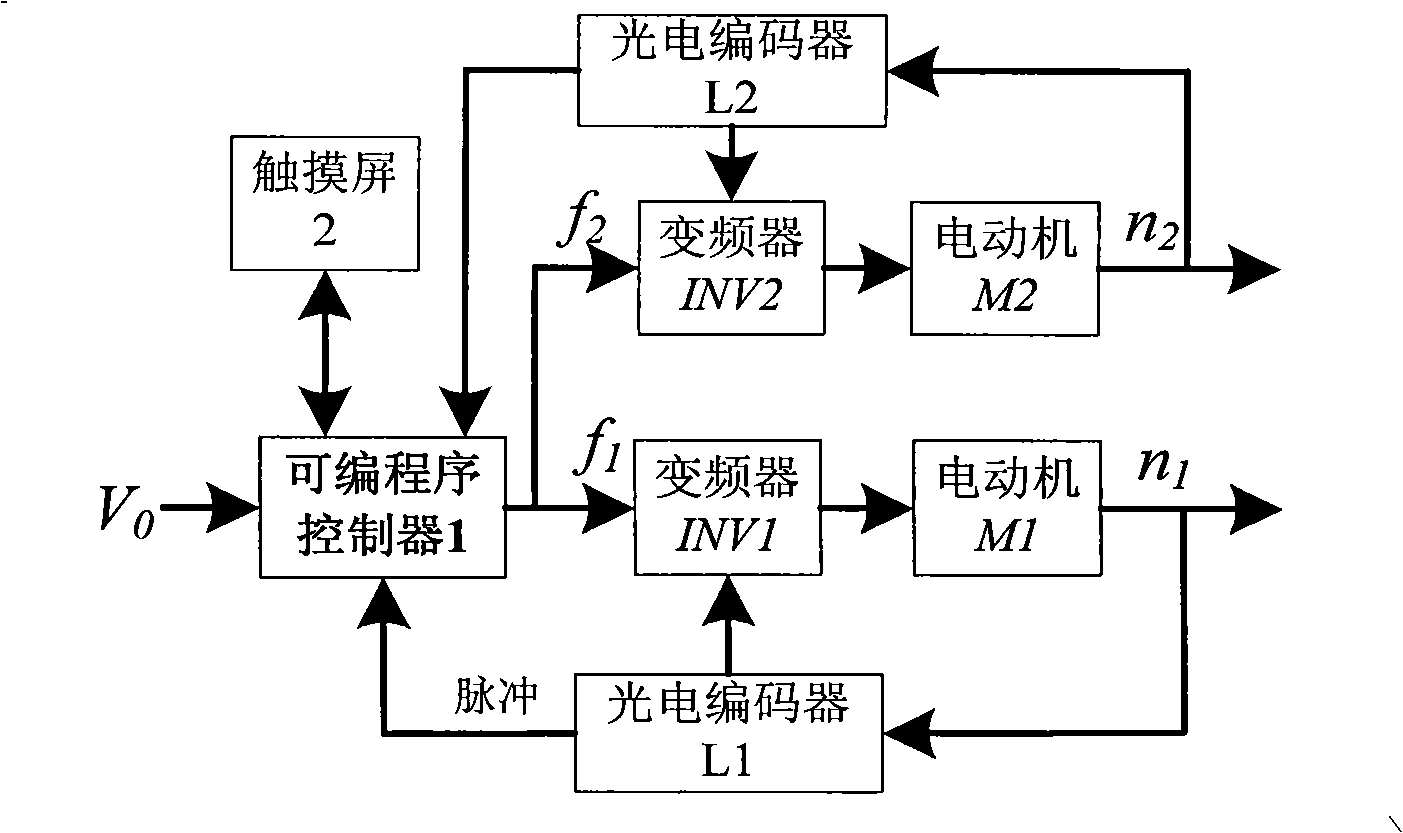

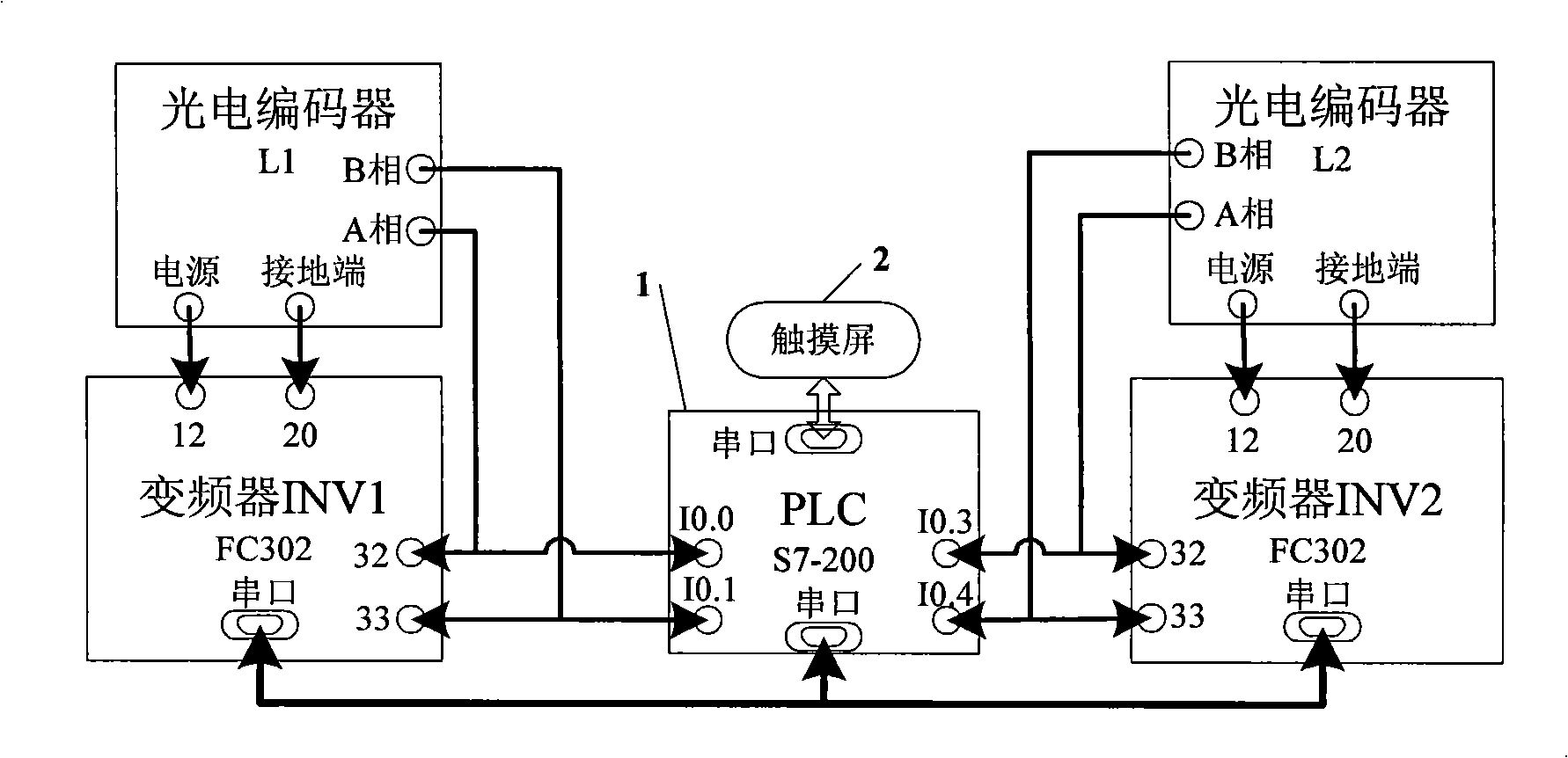

[0013] refer to figure 2 The jigger cloth line speed detection device includes a programmable logic controller 1 (PLC), a touch screen 2 for setting and displaying the speed, and two control units for winding and unwinding. The winding control unit includes a photoelectric encoder L1 and The servo system composed of inverter INV1 and the motor M1 driving the winding roller, the unwinding control unit includes the photoelectric encoder L2 and the servo system composed of the inverter INV2 and the motor M2 driving the unwinding roller; the photoelectric of the winding control unit The encoder L1 is installed on the tail shaft of the motor M1, the signal output terminal of the photoelectric encoder L1 is respectively connected with the input terminal of the programmable controller 1 and an input terminal of the inverter INV1, and the output terminal of the inverter INV1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com