Spraying type jig dyeing machine

A jigger and spray technology, applied in the field of dyeing and finishing machinery, can solve the problems of damage to the surface of the fabric, uneven dyeing, and difficult cleaning of impurities, and achieve the effects of reducing damage, good dyeing effect, and uniform spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

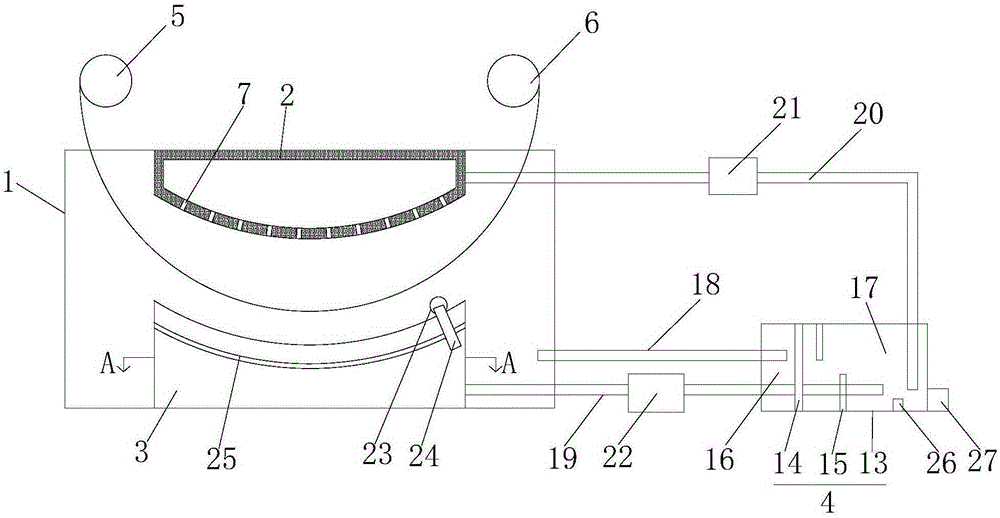

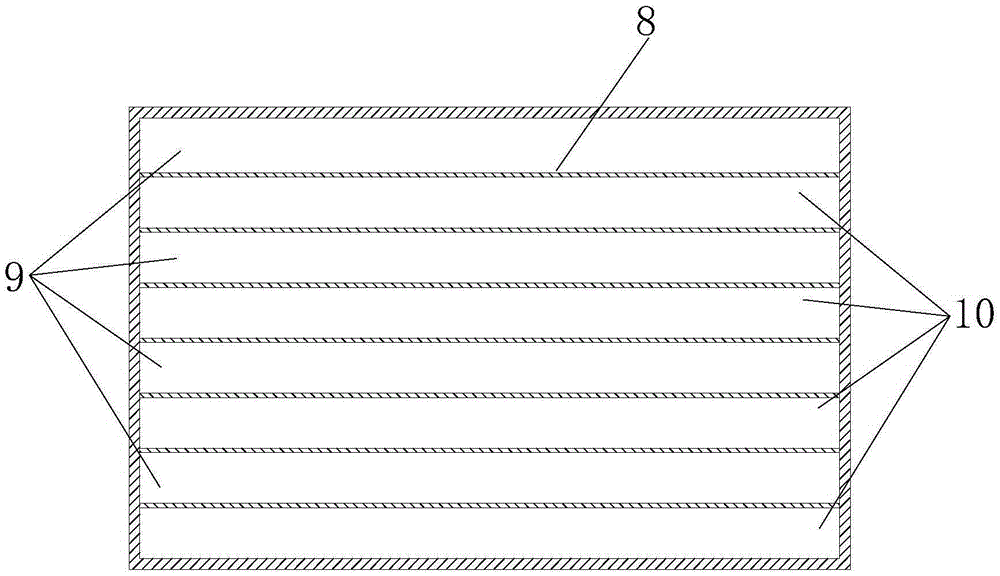

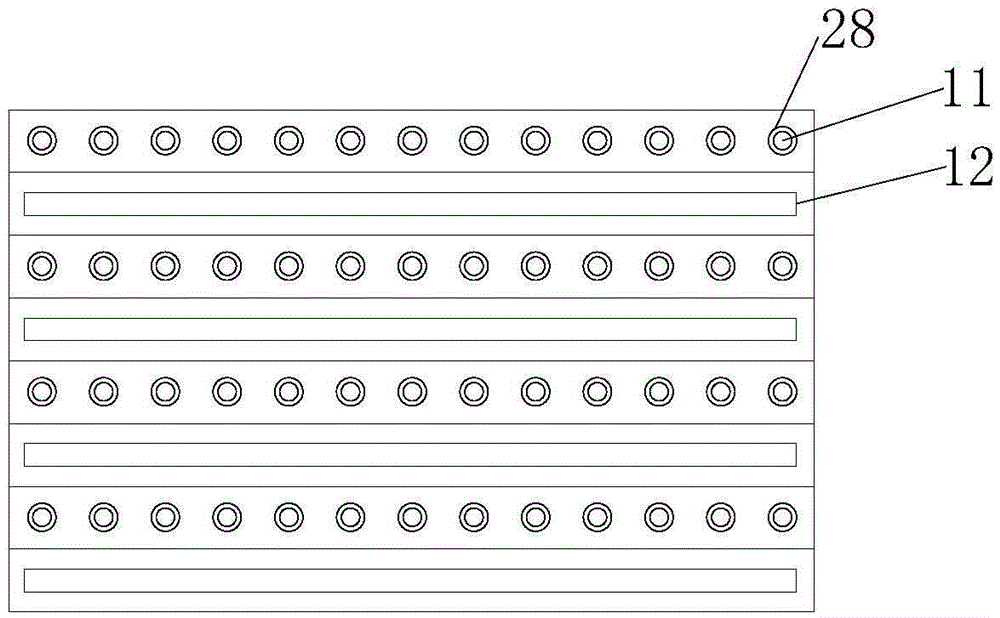

[0025] Such as figure 1 , figure 2 and image 3 as shown, figure 1 It is a structural schematic diagram of a spray jigger proposed by the present invention; figure 2 It is the A-A sectional schematic diagram of the lower spray recovery box in a spray jigger proposed by the present invention; image 3 It is a top view structure diagram of the middle and lower spray recovery box of a spray-type dyeing jigger proposed by the present invention.

[0026] refer to Figure 1-3 , a kind of spray jigger proposed by the present invention comprises a printing and dyeing box 1, an upper spray box 2, a lower spray recovery box 3 and a heating filter box 4;

[0027] The upper spray box 2 and the lower spray recovery box 3 are both arranged in the printing and dyeing box 1, the upper spray box 2 is located directly above the lower spray recovery box 3, the bottom wall of the upper spray box 2 is in a convex arc shape, and the lower The top wall of the spray recovery box 3 is in a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com