Continuous jig dyeing device for supercritical fluid and dyeing technology

A supercritical fluid, supercritical technology, applied in solvent dyeing, equipment configuration for processing textile materials, liquid/gas/vapor textile processing, etc., can solve the problems of short exposure time and low dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

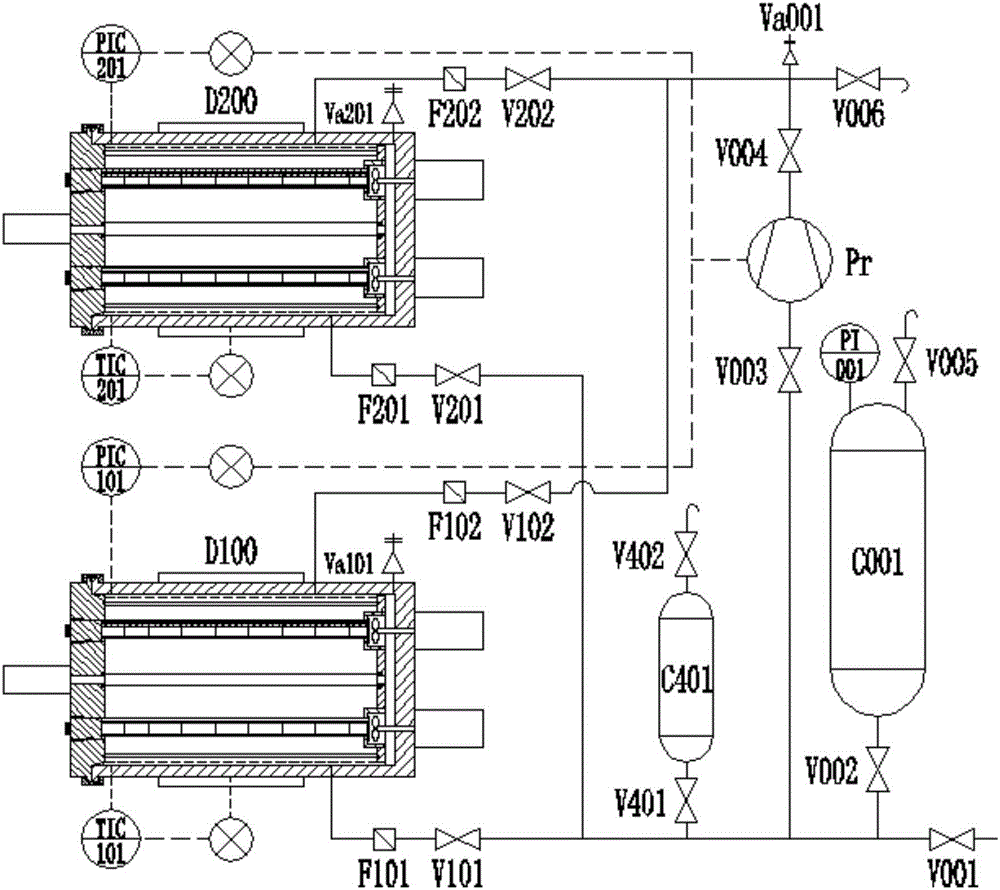

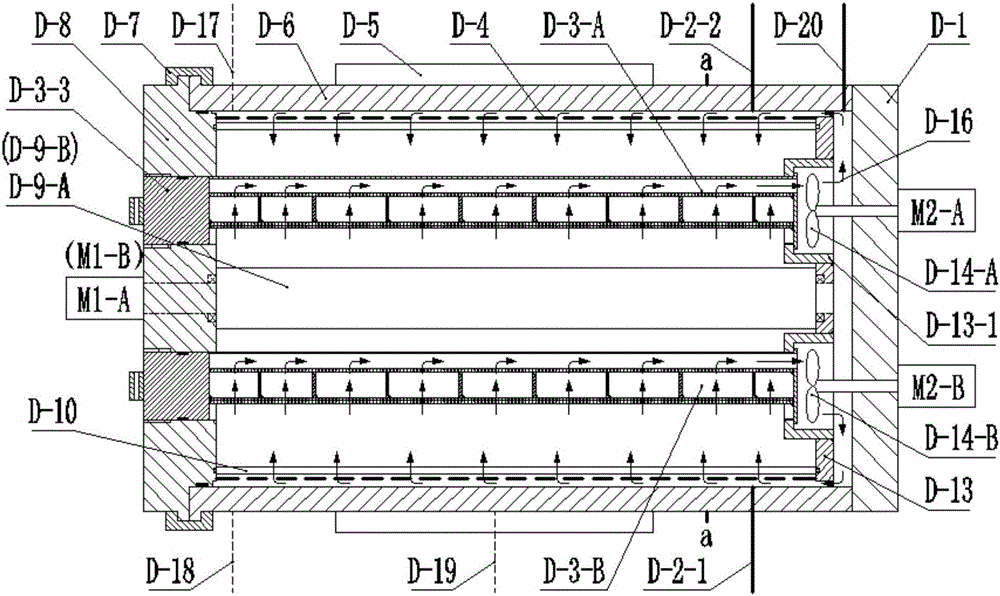

[0074] Example 1: Double integrated dyeing jigger supercritical fluid continuous dyeing device and dyeing process

[0075] Such as figure 1 As shown, the double integrated jigger supercritical fluid continuous dyeing device of the present invention consists of two integrated jiggers with the same structure, namely integrated jigger A D100 and integrated jigger B D200, filters F101, F102, F201, F202, booster Pr, supply tank C001, buffer tank C401, supply valve V001, switching valves V002, V003, V004, V101, V102, V201, V202, V401, emptying valves V005, V402, emptying valve V006, Safety valves Va001, Va101, Va201, temperature control instruments TIC101, TIC201, pressure control instruments PIC101, PIC201, pressure display instrument PI001, and pipes and fittings. Such as image 3 As shown, the integrated dye jiggers are equipped with pressure control instrument connection D-17, temperature control instrument connection D-18, heater temperature control wiring D-19, safety valve ...

Embodiment 2

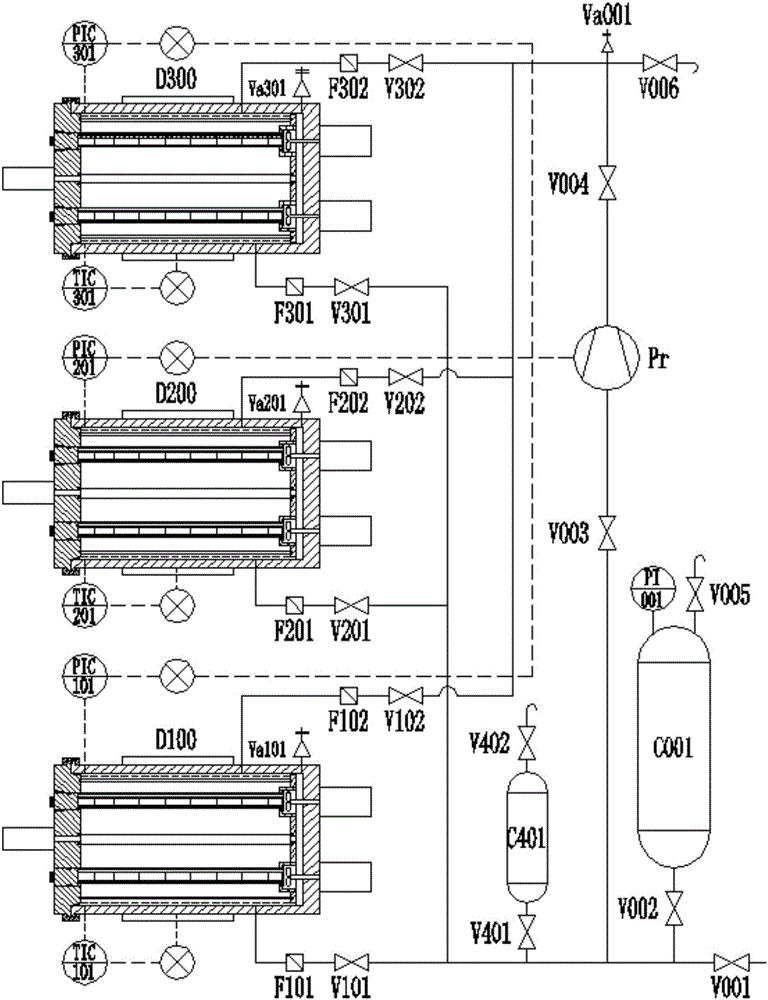

[0093] Example 2: Three-integrated dyeing jigger supercritical fluid continuous dyeing device and dyeing process

[0094] Such as figure 2 As shown, the supercritical fluid continuous dyeing device of the present invention consists of three integrated jiggers with the same structure, i.e. integrated jigger A D100, integrated jigger B D200 and integrated jigger CD300, filter F101, F102, F201, F202, F301, F302, supercharger Pr, supply tank C001, buffer tank C401, switching valve V002, V003, V004, V101, V102, V201, V202, V301, V302, V401, emptying valve V005, V402, vent valve V006, safety valves Va001, Va101, Va201, Va301, temperature control instruments TIC101, TIC201, TIC301, pressure control instruments PIC101, PIC201, PIC301, pressure display instrument PI001, and pipes and fittings. Such as image 3 As shown, the integrated dye jiggers are equipped with pressure control instrument connection D-17, temperature control instrument connection D-18, heater temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com