Modified polyphenylene sulfide based flame-retardant anti-cutting yarn, preparation method and gloves

A polyphenylene sulfide and polyphenylene sulfide fiber technology, applied in gloves, yarns, clothing, etc., can solve the problems of poor oxidation resistance, heat and oxidation resistance, insufficient yarn heat and oxygen resistance, and macromolecular breakage. Achieve the effect of low production cost and good market application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

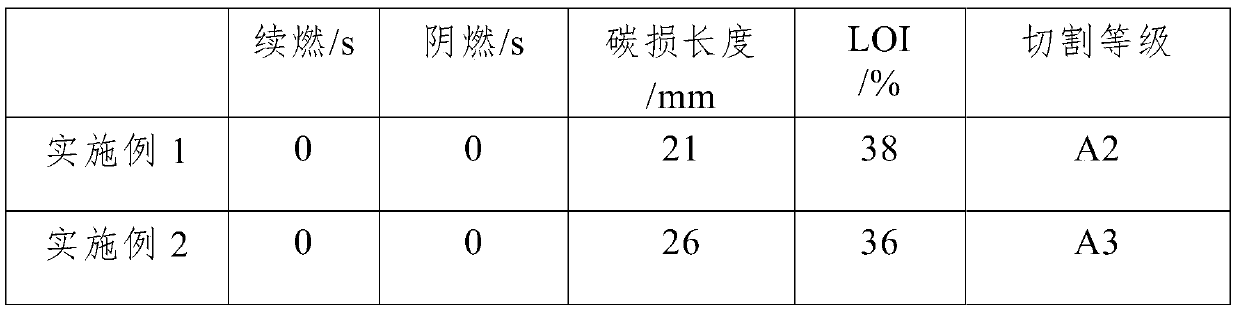

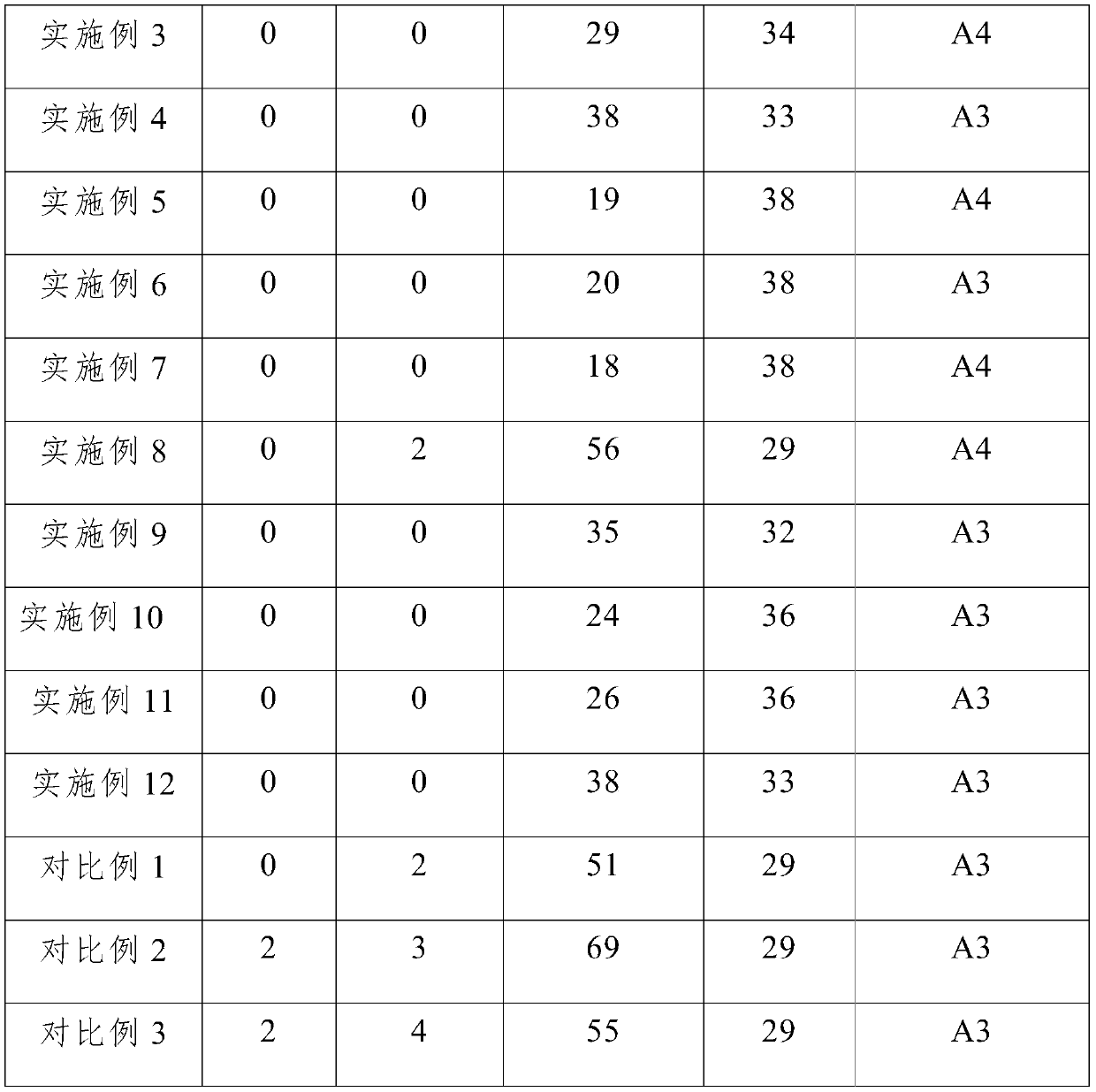

Examples

Embodiment 1

[0071]70wt% 1.5D*51mm modified polyphenylene sulfide fiber (modified by method 2), 10wt% 2D*51mm para-aramid staple fiber, 20wt% 50D glass fiber filament were cleaned by ring spinning machine Cottoning, carding, drawing, roving, spinning, and winding processes to produce core-spun single yarns with a count of 20S / 1 and a twist of 45 twists / 10cm, and plying to obtain 20S / 2 twists of 30 twists / 10cm Ply yarn. Two 20S / 2 yarns and one 20S / 1 yarn were used to weave gloves on a 10-needle glove machine, and the glove weight was 31.2g / piece.

Embodiment 2

[0073] 70wt% 2D*51mm modified polyphenylene sulfide fiber (modified by method 2), 10wt% 3D*51mm para-aramid staple fiber, 20wt% 100D glass fiber filament, are cleaned by ring spinning frame , carding, drawing, roving, spun yarn, and winding process to produce a core-spun single yarn with a count of 10S / 1 and a twist of 45 twists / 10cm, and a ply of 10S / 2 with a twist of 30 twists / 10cm yarn. One 10S / 2 yarn and one 10S / 1 yarn were used to weave gloves on a 10-needle glove machine, and the glove weight was 32.5g / piece.

Embodiment 3

[0075] 50wt% 1.5D*51mm modified polyphenylene sulfide fibers, 10wt% 4D*51mm para-aramid staple fibers, 40wt% 200D glass fiber filaments are cleaned, carded and drawn on a ring spinning frame , roving, spun yarn, and winding process to produce a core-spun single yarn with a count of 10S / 1 and a twist of 45 twists / 10cm, and a plied yarn with a twist of 10S / 2 and a twist of 30 twists / 10cm. One 10S / 2 yarn and one 10S / 1 yarn were used to weave gloves on a 10-needle glove machine, and the glove weight was 30.2g / piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com