Clothing softener and preparation method thereof

A technology of fabric softener and softener, which is applied in the field of fabric softener and its preparation, can solve the problems of poor hydrophilic air permeability, uncomfortable feeling, and unsmooth discharge of sweat, and achieve convenient operation, saving manpower and material resources, good air permeability and Moisture wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

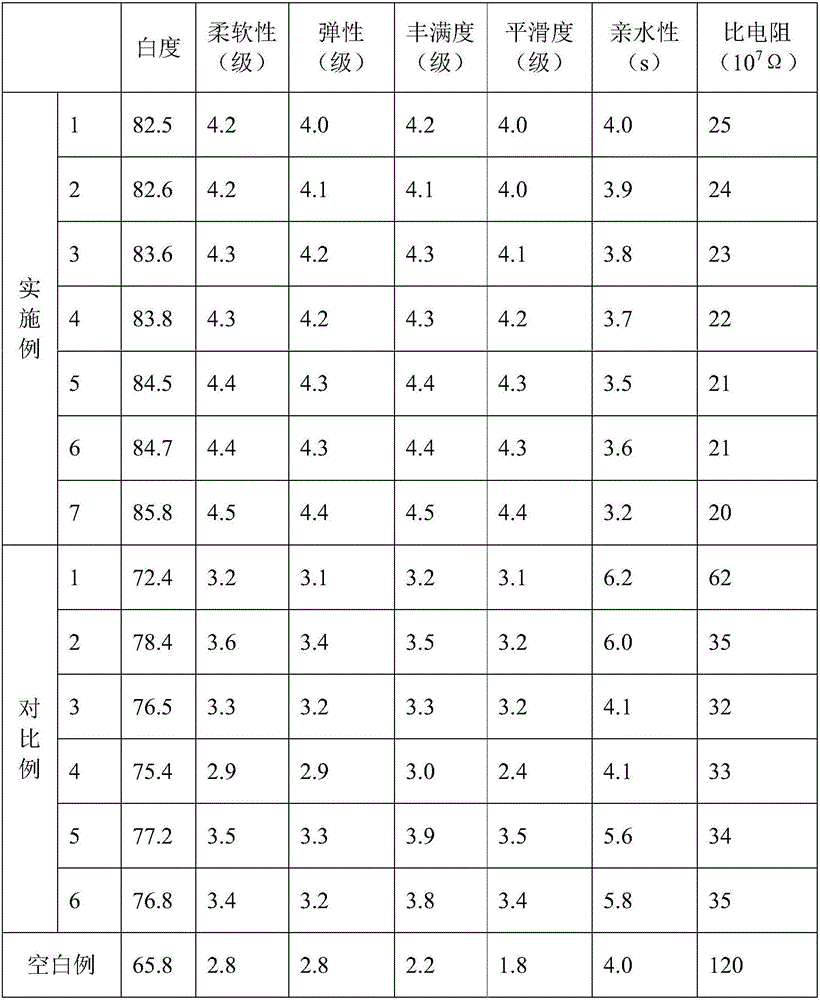

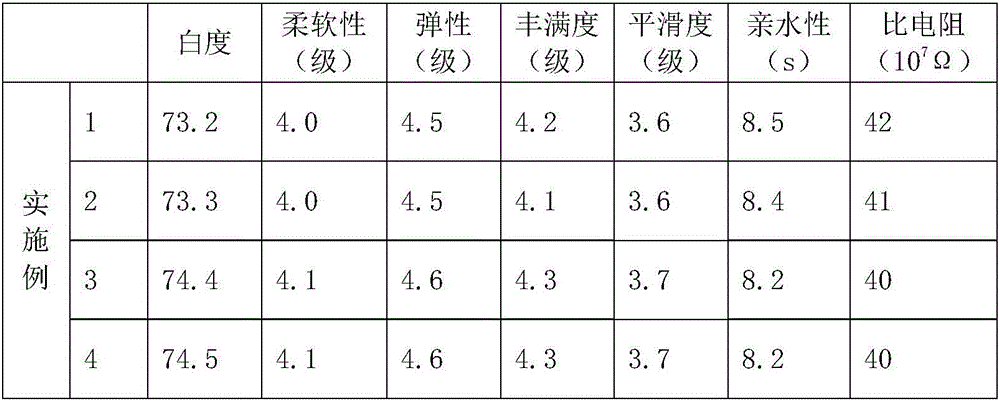

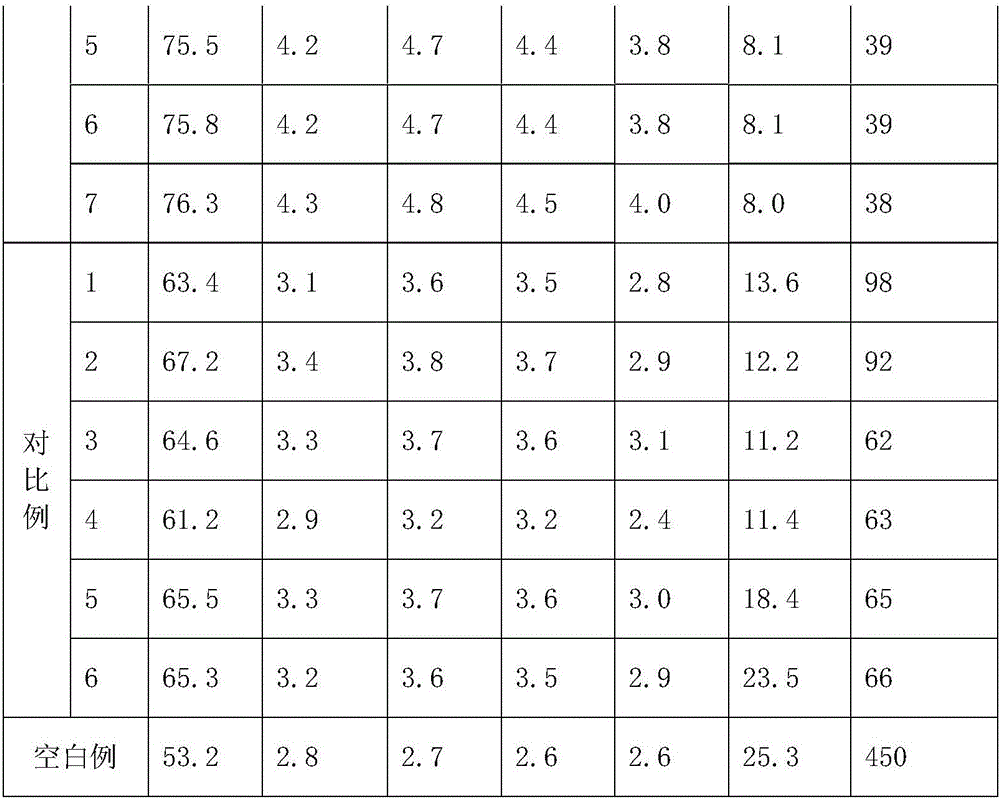

Examples

preparation example Construction

[0028] In the preparation process of hydrophilic silicone oil softener, epoxy-modified silicone oil and allyl alcohol undergo polycondensation reaction under the action of alkaline catalyst to generate hydrophilic silicone oil polymer, in order to strengthen hydrophilic silicone oil polymer Water-soluble, add emulsifier, so that the hydrophilic silicone oil polymer can be stably dispersed in the aqueous solution, that is, the hydrophilic silicone oil softener is obtained.

[0029] In a preferred embodiment of the present invention, the molecular weight of the epoxy-modified silicone oil is 8000-12000, preferably 10000; the emulsifier used is selected from ethylene glycol monobutyl ether and / or dimethylethanolamine, preferably ethylene glycol monobutyl ether Alcohol monobutyl ether; The basic catalyst used is selected from one or at least two of potassium hydroxide, sodium hydroxide and ammonium hydroxide, preferably ammonium hydroxide.

[0030] In a preferred embodiment of the...

Embodiment 1

[0044] This embodiment provides a fabric softener, comprising the following components in parts by mass: 2 parts of hydrophilic silicone oil softener, 5 parts of hydrophilic polyester polyether block copolymer softener, dialkyl di 5 parts of methyl ammonium chloride, 85 parts of demineralized water, 0.1 part of nano-microcapsule slow-release fragrance agent, 0.05 part of plant pigment, 0.4 part of kasone, 2 parts of sodium chloride, 1 part of hydroxypropyl methylcellulose;

[0045] Wherein, the hydrophilic silicone oil softener is prepared by the following method:

[0046] Weigh 1000g of epoxy-modified silicone oil with a molecular weight of 8000, put 110g of allyl alcohol into a reaction vessel and mix evenly, and react at 85°C for 3 hours under the catalysis of ammonium hydroxide, then heat up to 120°C for 4 hours. Then the reaction container was evacuated for 15 minutes, and then added with a concentration of 99% ethylene glycol monobutyl ether 1000g, which was stirred even...

Embodiment 2

[0049] This embodiment provides a fabric softener, comprising the following components in parts by mass: 8 parts of hydrophilic silicone oil softener, 1 part of hydrophilic polyester polyether block copolymer softener, diamide ethyl 15 parts of alkoxy ammonium chloride, 70 parts of demineralized water, 0.3 part of nano-microcapsule slow-release fragrance agent, 0.15 part of plant pigment, 0.6 part of kason, 4 parts of sodium chloride, 3 parts of hydroxypropyl methylcellulose;

[0050] Wherein, the hydrophilic silicone oil softener is prepared by the following method:

[0051] Weigh 1000g of epoxy-modified silicone oil with a molecular weight of 12000, put 90g of allyl alcohol into a reaction vessel and mix evenly, and react at 85°C for 3 hours under the catalysis of ammonium hydroxide, then heat up to 120°C for 4 hours. Then the reaction container was evacuated for 15 minutes, and then added with a concentration of 99% ethylene glycol monobutyl ether 1000g, which was stirred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com