Novel polyester cotton blended yarn and production process thereof

A technology of polyester-cotton blending and production technology, which is applied in the direction of yarn, textiles and papermaking, can solve the problems of low pilling resistance, uneven yarn dryness and high production cost, and achieve bright color, uniform dryness, The effect of high coloring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

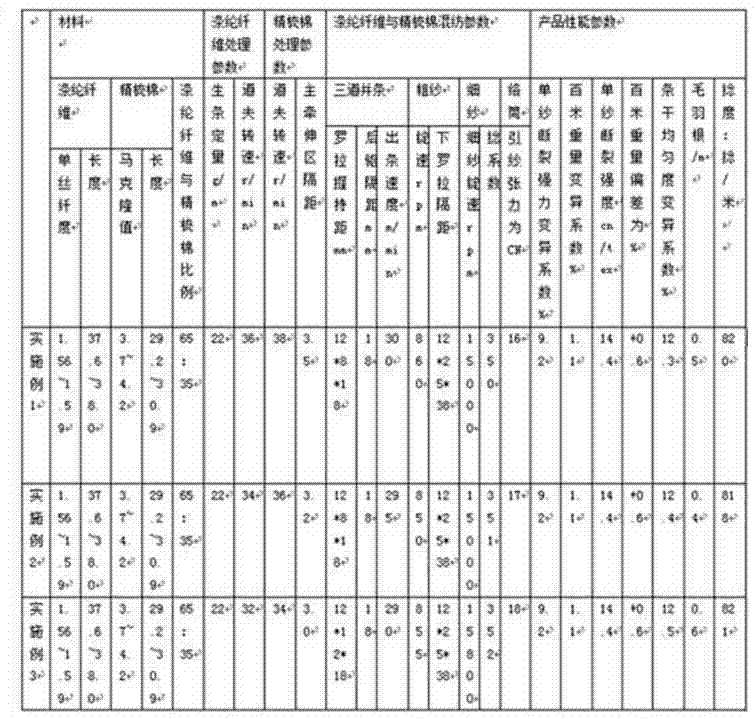

Examples

Embodiment 1

[0025] A new type of polyester-cotton blended yarn, including cationic upgraded modified polyester fiber and combed cotton. The polyester-cotton blended yarn is uniformly mixed with 65% polyester fiber and 35% combed cotton.

[0026] The above-mentioned new polyester-cotton blended yarn is blended with cationic modified polyester fiber and combed cotton. The monofilament fineness of cationic modified polyester fiber is 1.56-1.59dtex, and the length is 37.6-38.0mm; the micronaire value of combed cotton is 3.7~4.2, the length is 29.2~30.9mm, the specific steps are as follows:

[0027] The first step, polyester fiber treatment: the treatment process is followed by cleaning, carding and pre-merging. Among them, the cleaning process adopts the principle of short process and light blow to reduce the damage and rubbing of polyester fibers; the carding process, according to the polyester fiber In order to ensure the carding and smooth transfer of polyester fibers, take measures to lig...

Embodiment 2

[0032] A new type of polyester-cotton blended yarn, consisting of cationic upgraded modified polyester fiber and combed cotton, which is evenly mixed with 65% polyester fiber and 35% combed cotton.

[0033] The above-mentioned new polyester-cotton blended yarn is blended with cationic modified polyester fiber and combed cotton. The monofilament fineness of cationic modified polyester fiber is 1.56-1.59dtex, and the length is 37.6-38.0mm; the micronaire value of combed cotton is 3.7~4.2, the length is 29.2~30.9mm, the specific steps are as follows:

[0034] The first step, polyester fiber treatment: the treatment process is followed by cleaning, carding and pre-merging. Among them, the cleaning process adopts the principle of short process and light blow to reduce the damage and rubbing of polyester fibers; the carding process, according to the polyester fiber In order to ensure the carding and smooth transfer of polyester fibers, the sliver weight is set at 22g / m, and the doff...

Embodiment 3

[0039] A new type of polyester-cotton blended yarn, consisting of cationic upgraded modified polyester fiber and combed cotton, which is evenly mixed with 65% polyester fiber and 35% combed cotton.

[0040] The first step, polyester fiber treatment: the treatment process is followed by cleaning, carding and pre-merging. Among them, the cleaning process adopts the principle of short process and light blow to reduce the damage and rubbing of polyester fibers; the carding process, according to the polyester fiber In order to ensure the carding and smooth transfer of polyester fibers, take appropriate measures to lighten the weight of raw sliver and reduce the speed of doffer. The weight of raw sliver is set at 22g / m, and the speed of doffer is 32r / min;

[0041] The second step, combed cotton treatment: the treatment process is followed by blowing carding, pre-merging, sliver winding and combing. Doffer speed, doffer speed is 34r / min, imported Graff card clothing is used to increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com