Paper type collecting device

It is a paper-based and accumulative technology, which is applied in the directions of transportation and packaging, sending objects, and thin material processing. It can solve the problems of complicated control content and difficult deceleration, and achieve the effects of reducing rebound, preventing scatter, and reducing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

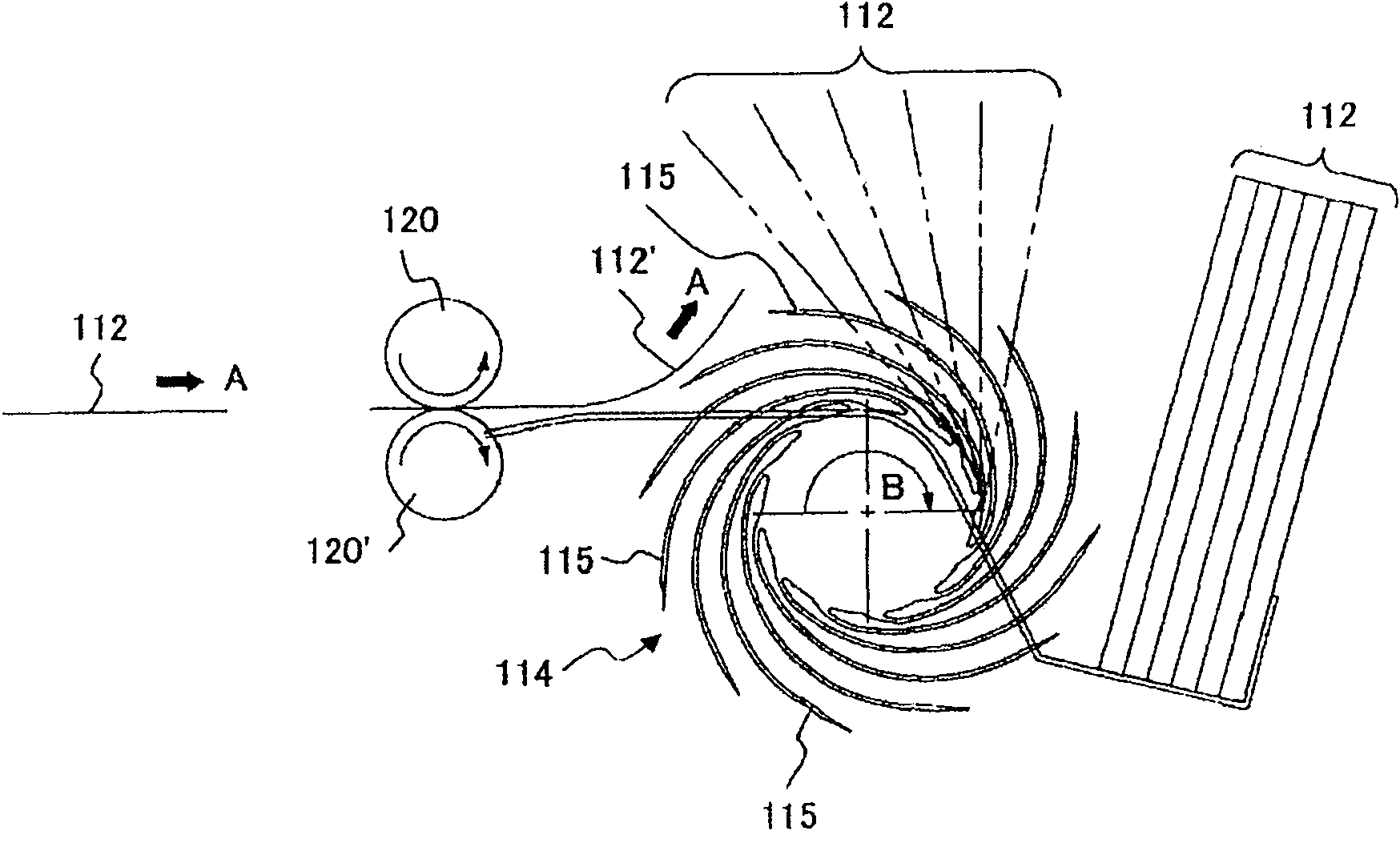

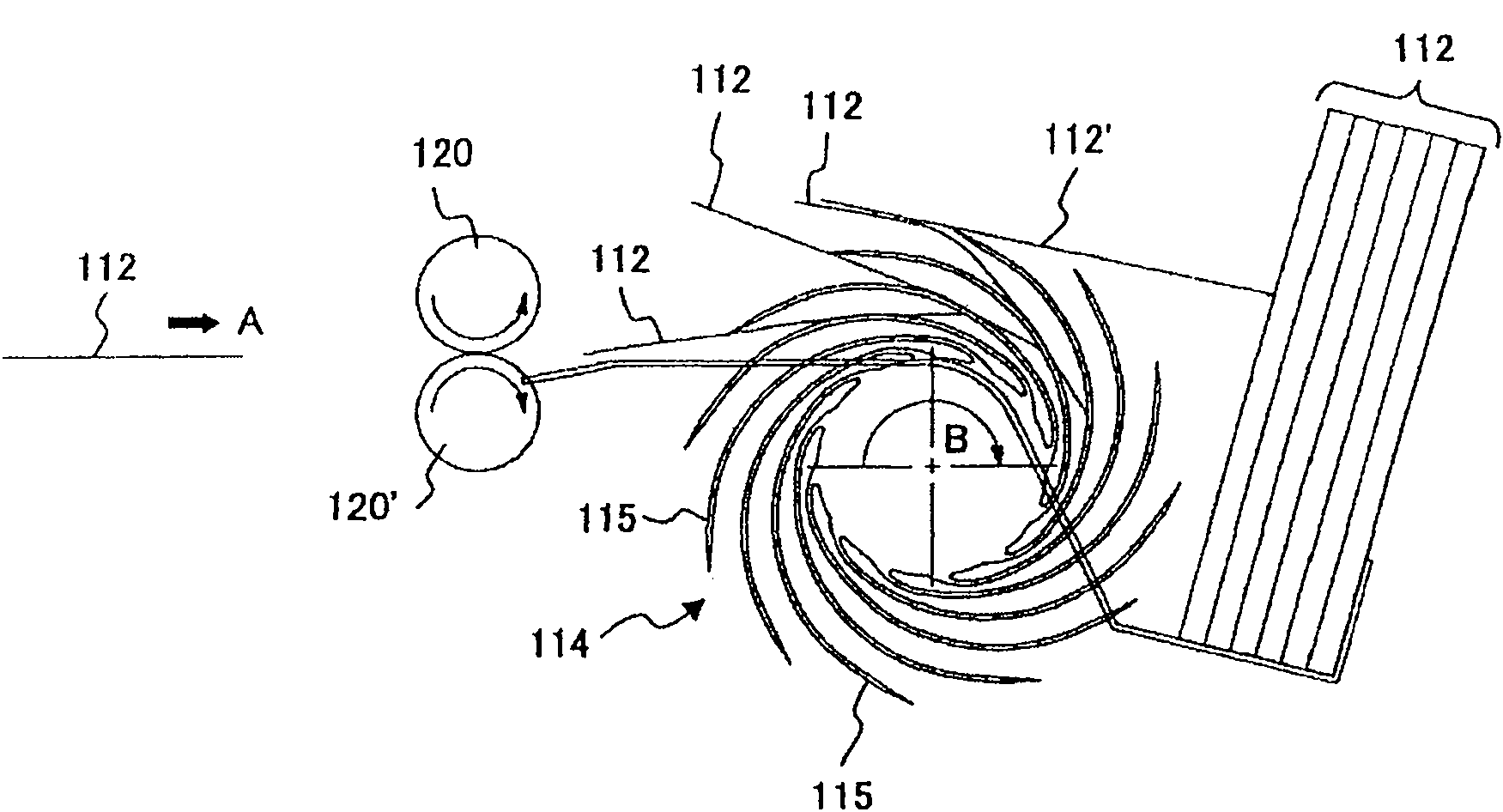

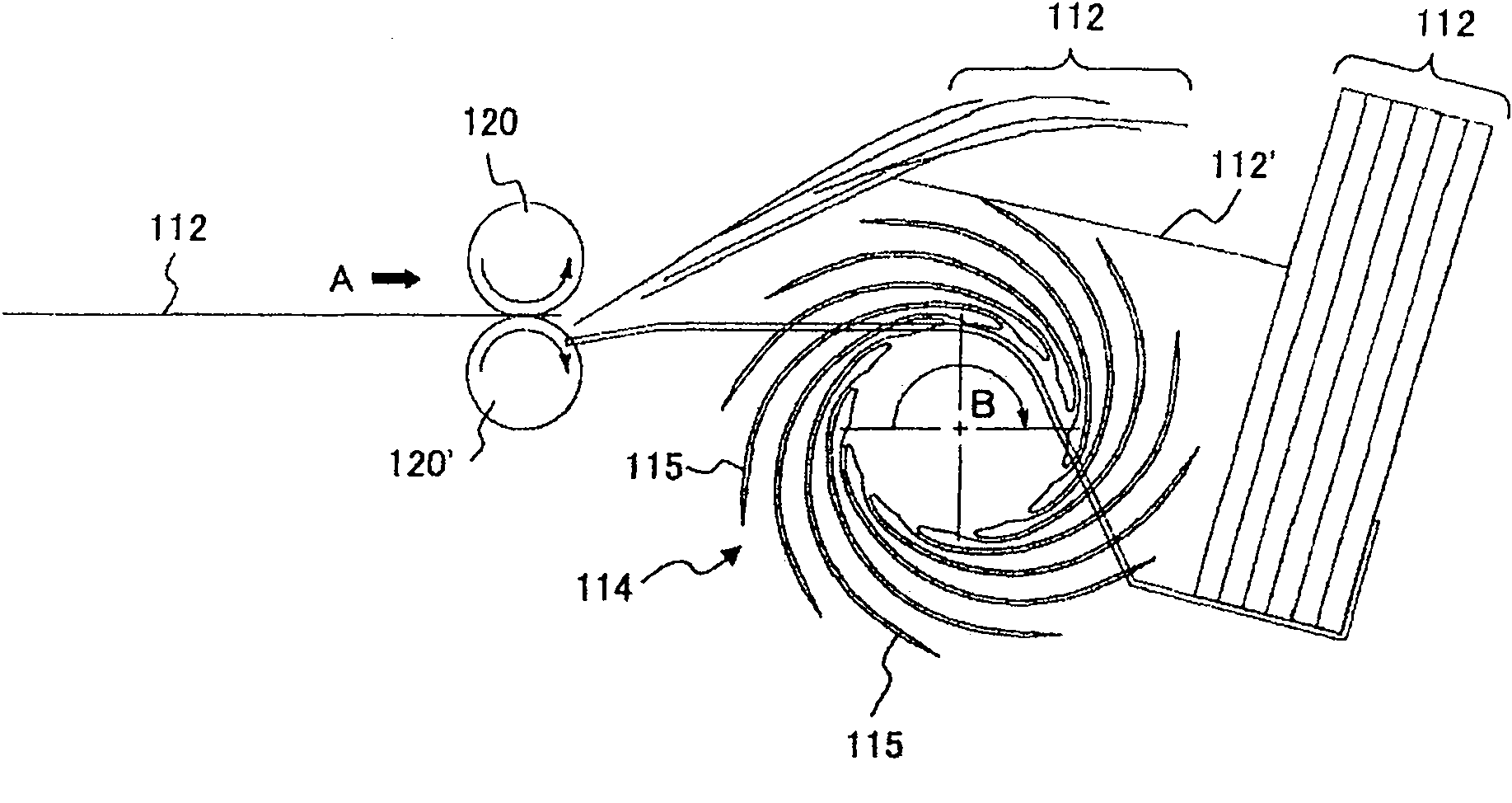

[0042] image 3 It is a side view of the sheet stacking device of the first embodiment, Figure 4A is the front view of the impeller, Figure 4B and Figure 4C is its side view.

[0043] exist image 3 Among them, the paper stacking device 10 is a device that vertically accommodates bills, checks, securities, and the like as paper bills, for example, paper bills 12 .

[0044] The paper stacking device 10 includes: an impeller 14 having a plurality of blades 15 on the outer peripheral surface, and the impeller 14 accommodates the banknotes 12 between adjacent blades 15, 15 and rotates and conveys them in the direction of the arrow F; The accumulating portion 16 accumulates the banknotes 12 conveyed by the impeller 14 ;

[0045] In addition, the banknotes 12 are continuously supplied to the impeller 14 one by one at a constant speed in a fixed direction by the transport roller pair 20, 20'.

[0046] Furthermore, the banknotes 12 are conveyed one by one while being rotated by...

no. 2 approach

[0082] Figure 7A It is a front view of the impeller of the sheet stacking device of the second embodiment, Figure 7B is its side view. In addition, the same code|symbol is attached|subjected to the same or equivalent part as 1st Embodiment, and the description is abbreviate|omitted.

[0083] In this embodiment, if Figure 7A and Figure 7B As shown, a cylindrical roller 30 fixed to the drive shaft 22 is arranged between a pair of symmetrical first and second impellers 14A, 14A.

[0084] In this way, even when the roller 30 is disposed between the first and second impellers 14A, 14A, an upward convex crease 24 can be formed at the center of the banknote 12 in the width direction (see Figure 7B ). Thereby, the frictional force between the banknote 12 and blade|wing 15A, 15A etc. increases, and it can prevent that the banknote 12 detached from the blade wheel 14 and scattered during rotary conveyance.

[0085] In this embodiment, if Figure 7A As shown, the radius of the ...

no. 3 approach

[0095] Figure 8A It is a front view of the impeller of the sheet stacking device of the third embodiment, Figure 8B is its side view. In addition, the same code|symbol is attached|subjected to the same or equivalent part as 1st Embodiment, and the description is abbreviate|omitted.

[0096] In this embodiment, if Figure 8A As shown, protrusions 32 are formed on the outer surfaces of the blades 15A, 15A of the respective first and second impellers 14A, 14A.

[0097] In this embodiment, in Figure 8A Among them, the protruding portion 32 is formed when the banknote 12 comes into contact with the tip g of one blade 15A-1 of the adjacent blades of the first and second impellers 14A, 14A when the banknote 12 comes into contact with the other blade 15A-2. The contact point h.

[0098] In addition, in this embodiment, although the case where the protrusion part 32 was formed in the same position as the contact point h was demonstrated, it is not limited to this. For example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com