Fabrication method of needling/spunlace and electrostatic spinning compound filtering material

A technology of composite filter material and manufacturing method, which is applied in the textile field, can solve the problems of low filter membrane strength and difficulty in achieving ultrafine particle filtration efficiency above 99%, and achieve the effects of low resistance, high breaking strength and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

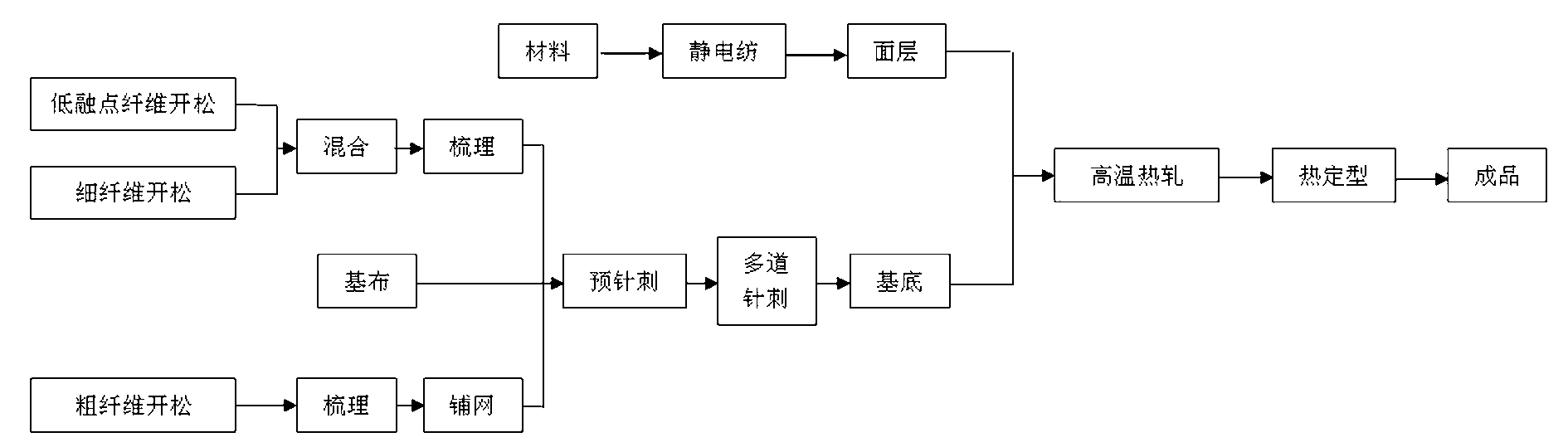

[0021] (1) High-performance filter substrates are prepared by acupuncture or spunlace:

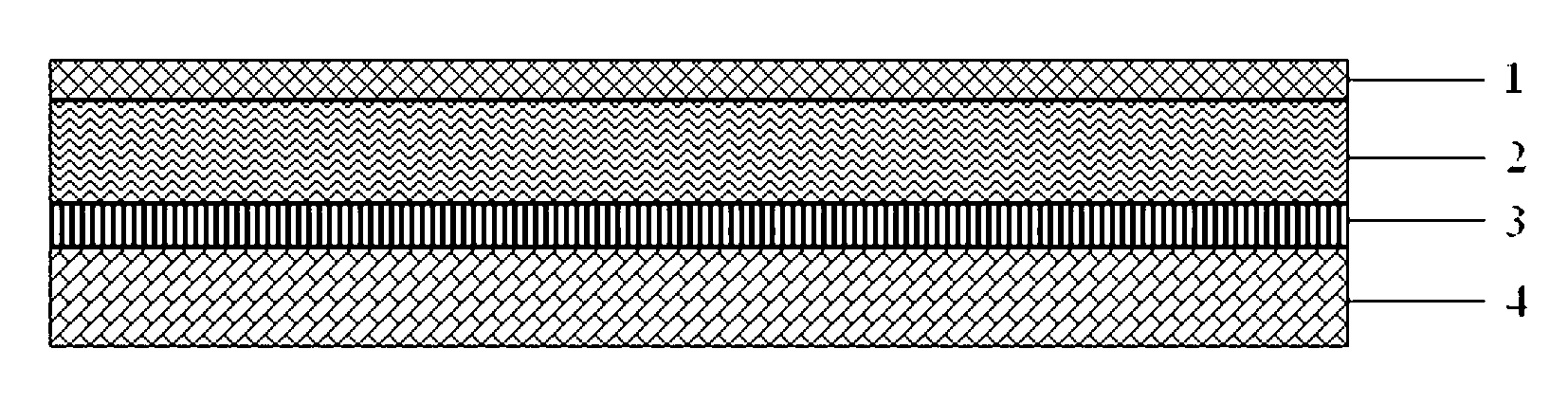

[0022] The high-performance filter material base is composed of three layers: the bottom layer is made of 7dtex polyester fiber, the middle layer is a high-strength polyester base fabric with a breaking strength of 1500N / 5cm in the warp direction and a breaking strength of 1500N / 5cm in the weft direction, and the upper layer is made of 30% by mass, 1.5dtex low melting point polyester fiber and 0.8dtex polyester fiber;

[0023] (2) The surface layer of high-performance polyester filter material is made by electrospinning, and the filtration efficiency of the surface layer of high-performance filter material for 2μm ultrafine particles reaches 99.9%;

[0024] (3) Put the surface layer of the filter material prepared in step (2) on the base of the filter material prepared in step (1), hot rolling and compounding at 250°C, and then heat setting at 180~230°C to make high-performance filter mat...

Embodiment 2

[0027] (1) High-performance filter substrates are prepared by acupuncture or spunlace:

[0028] The high-performance filter material base is composed of three layers: the bottom layer is made of 2.5dtex PPS fiber, the middle layer is a high-strength PPS base cloth with a radial breaking strength of 1200N / 5cm and a transverse breaking strength of 1000N / 5cm, and the upper layer is made of 50% mass fraction, Composition of 1.0dtex low melting point PPS fiber and 1.1dtex PPS fiber;

[0029] (2) Electrospinning is used to prepare high-performance PPS filter material surface layer: the filtration efficiency test of the high-performance filter material surface layer for 2μm ultrafine particles reaches 99.9%;

[0030] (3) Put the surface layer of the filter material prepared in step (2) on the base of the filter material prepared in step (1), hot rolling and compounding at 260°C, and then heat setting at 200~280°C to make high-performance filter material;

[0031] (4) The obtained h...

Embodiment 3

[0033] (1) High-performance filter substrates are prepared by acupuncture or spunlace:

[0034] The high-performance filter base is composed of three layers: the bottom layer is made of 5dtex polyimide fiber, the middle layer is a high-strength polyimide base fabric with a radial breaking strength of 1300N / 5cm and a transverse breaking strength of 1200N / 5cm, and the upper layer is made of Composition of 20% mass fraction, 2.0dtex low melting point polyimide fiber and 2.2dtex polyimide fiber;

[0035] (2) The high-performance polyimide filter material surface layer is made by electrospinning, and the filtration efficiency of the high-performance filter material surface layer for 2μm ultrafine particles reaches 99.99%;

[0036] (3) Place the surface layer of the filter material obtained in step (2) on the base of the filter material obtained in step (1), hot-roll and compound at 280°C, and then heat-set at 250~260°C to make a high-performance filter material;

[0037] (4) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com