Production method for pure cotton single direction wet guiding functional nonwovens

A non-woven fabric, functional technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of losing water repellency on one side of the non-woven fabric, and it is difficult to arrange the droplets in a regular manner. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

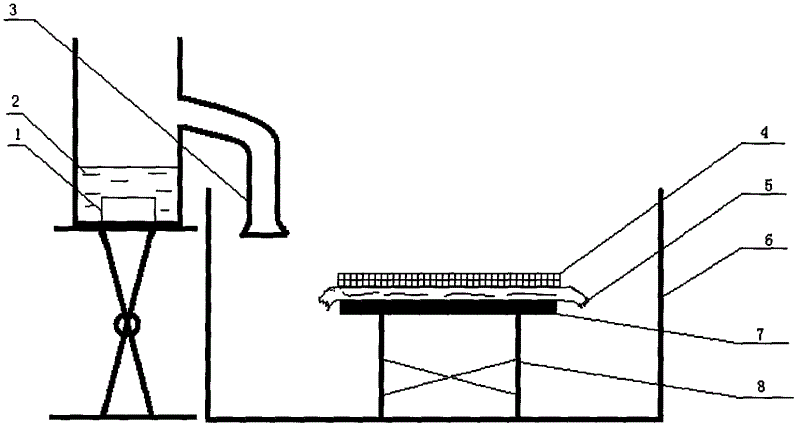

[0033] A method for preparing pure cotton unidirectional moisture-conducting functional nonwoven fabric, characterized in that: the preparation method of pure cotton unidirectional moisture-conducting functional nonwoven fabric is as follows:

[0034] A Preparation of fluorine-containing water-repellent finishing agent solution 2

[0035] Dissolve the fluorine-containing water-repellent finishing agent in distilled water, and stir until it is uniformly dispersed to prepare a mixed solution with a mass fraction of the fluorine-containing water-repellent finish agent of 1% to 30%, and then add penetrant to the mixed solution, the penetrant The mass is 1 to 3 times that of the fluorine-containing water-repellent finishing agent, and the type is sodium α-alkenyl sulfonate or fatty alcohol polyvinyl chloride ether or sulfated castor oil or sodium alkyl sulfonate or sodium alkylbenzene sulfonate or sodium alkylsulfate, sodium secondary alkylsulfonate, sodium secondary alkylsulfate, ...

Embodiment 1

[0043] A Dissolve 1g of AG-XF fluorine-containing water repellent in 99g of distilled water, stir well until it is evenly dispersed, and make AG-XF

[0044] A mixed solution with a mass fraction of fluorine-containing water-repellent agent of 1%, and then 1 g of sodium α-olefin sulfonate penetrant was added to the mixed solution to obtain an AG-XF fluorine-containing water-repellent solution to be ultrasonically atomized.

[0045] B Place the ultrasonic atomizer in the AG-XF fluorine-containing water repellent solution for ultrasonic atomization to prepare AG-XF fluorine-containing water repellent atomized microbeads, and the particle size of the atomized microbeads is 10 μm.

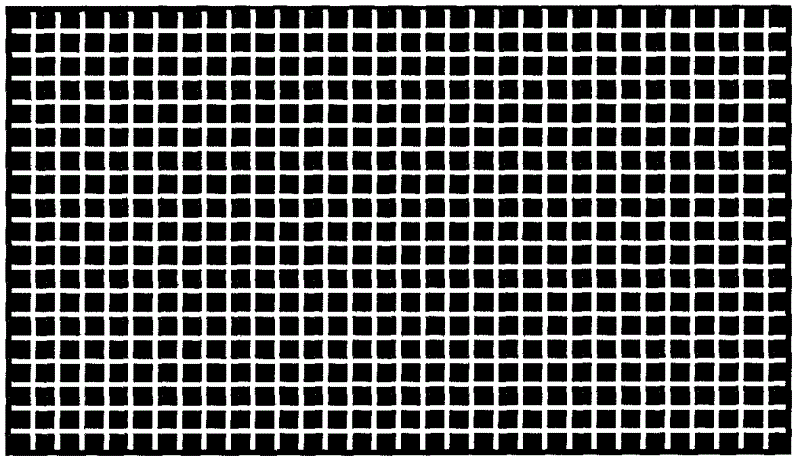

[0046] C Place the pure cotton non-woven fabric on a glass plate, lay a 20-mesh screen on the upper surface of the pure cotton non-woven fabric, and place it in a container through a bracket to make the pure cotton non-woven fabric The woven cloth is in the middle of the container, and the AG-XF fluorin...

Embodiment 2

[0048] A Dissolve 1g of AG-XF fluorine-containing water repellent in 99g of distilled water, stir well until it is uniformly dispersed, and make a mixed solution of AG-XF fluorine-containing water repellent with a mass fraction of 1%, and then add 2g to the mixed solution Fatty alcohol polyvinyl chloride ether to obtain the AG-XF fluorine-containing repellent solution to be ultrasonically atomized.

[0049] B Place the ultrasonic atomizer in the AG-XF fluorine-containing water repellent solution for ultrasonic atomization to prepare AG-XF fluorine-containing water repellent atomized microbeads, and the particle size of the atomized microbeads is 10 μm.

[0050] C Place the pure cotton non-woven fabric on a glass plate, lay a 30-mesh screen on the upper surface of the pure cotton non-woven fabric, and place it in a container through a bracket to make the pure cotton non-woven fabric The cotton non-woven fabric is in the middle of the container, and the AG-XF fluorine-containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com