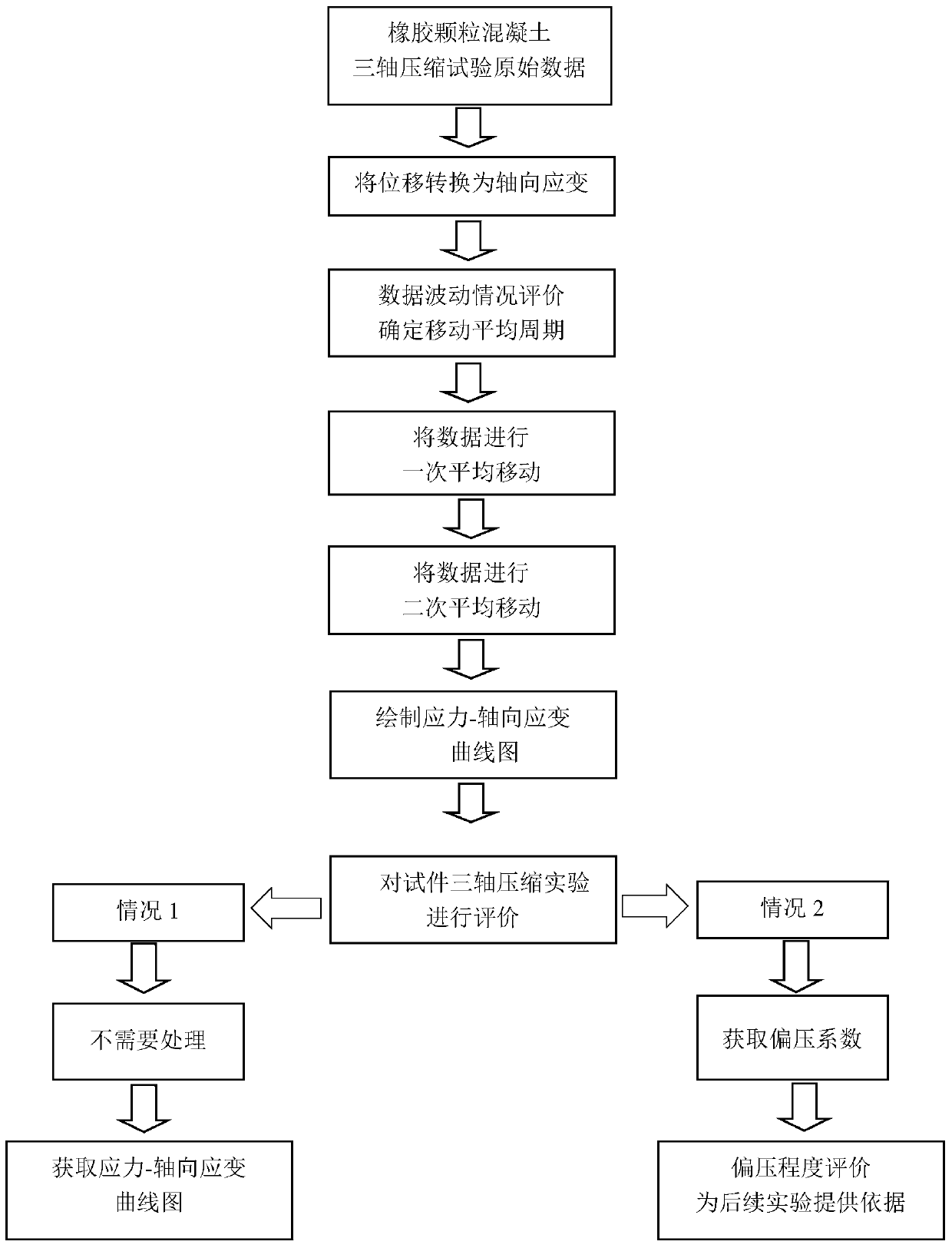

A method for processing experimental data of rubber particle concrete triaxial compression

A triaxial compression, rubber particle technology, applied in the direction of applying stable tension/compression to test material strength, measuring devices, instruments, etc., can solve the problem of high cost of triaxial testing machine, limited matching with rubber particle concrete, compression amount limited and other problems, to achieve the effect of accurate and effective treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

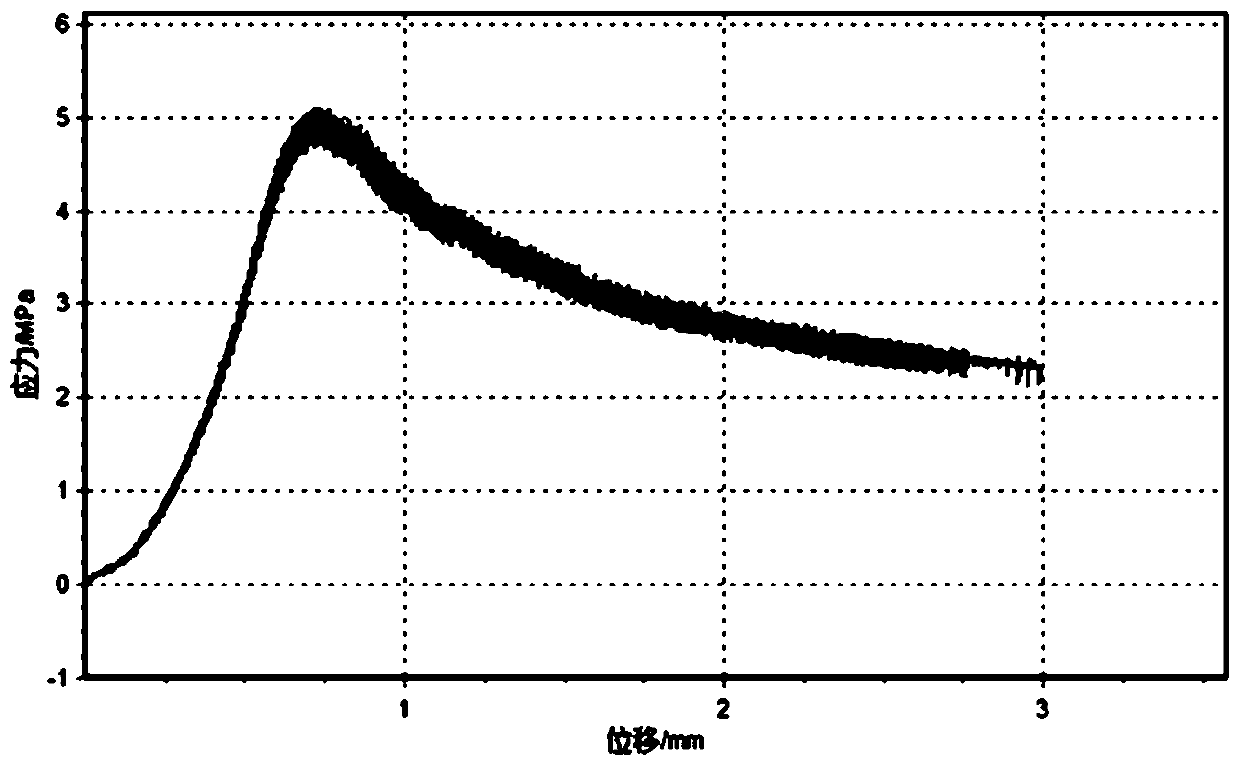

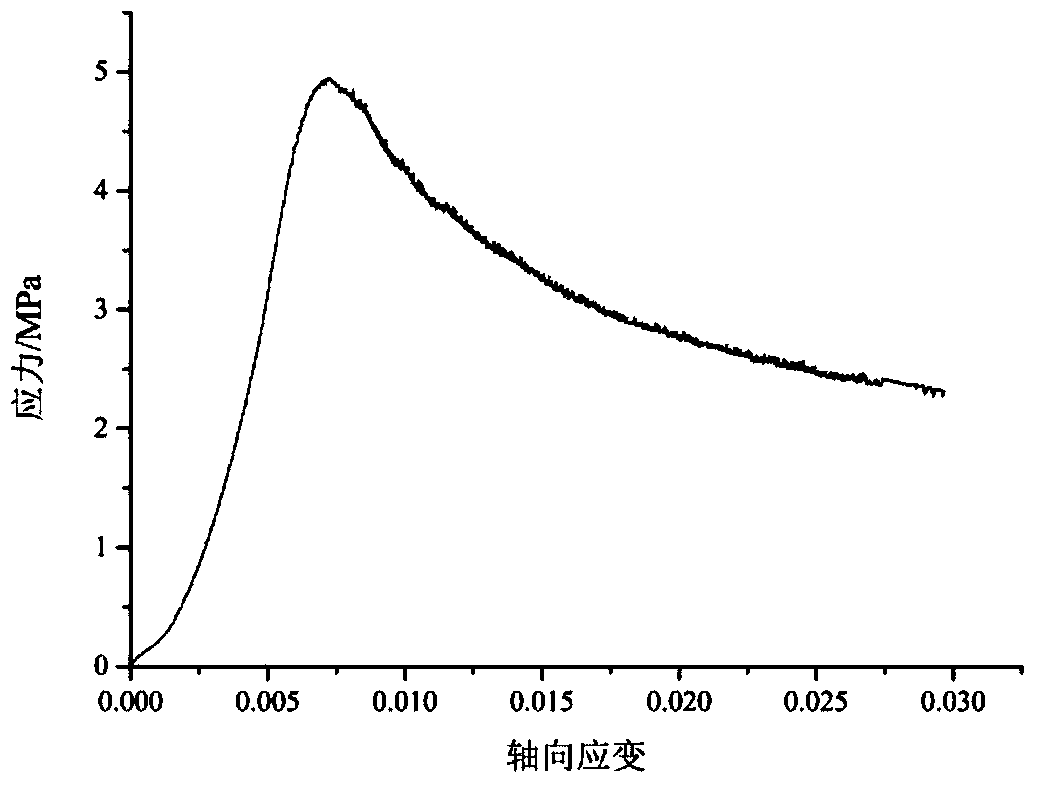

[0059] Taking the rubber particle concrete standard specimen with a mass ratio of rubber particles of 15% as an example, the triaxial compression test specimen is carried out at a confining pressure of 0 MPa, and the initial height measurement value of the specimen is H 0 =101.00mm, the rubber added in the experiment is styrene-butadiene rubber, and the experiment obtained 5413 rows of raw data output from the triaxial compression test of rubber particle concrete, and the data of the first 30 rows are shown in Table 1. The original stress-displacement curve is shown in figure 2 shown.

[0060] Table 1 shows the output raw data (the first 30 lines) of the rubber particle concrete triaxial compression test, as follows:

[0061] serial number

1

2

3

4

5

6

7

8

9

10

11

12

13

time

load

displacement

deformation 1

stress

Strain 1

Strain 2

Confining pressure

peripheral displa...

Embodiment 2

[0083] Taking the rubber particle concrete standard specimen with a mass ratio of 20% rubber particles as an example, the triaxial compression test specimen is carried out at a confining pressure of 8MPa, and the initial height measurement value of the specimen is H 0 =101.53mm, the rubber added in the experiment is styrene-butadiene rubber, and the experiment obtained a total of 11,577 rows of raw data output from the rubber particle concrete triaxial compression test. The first 30 rows of data are shown in Table 4. The output of the rubber particle concrete triaxial compression test The original stress-displacement curve is shown in Figure 4 shown.

[0084] Table 4 shows the output raw data (the first 30 lines) of the rubber particle concrete triaxial compression test, as follows:

[0085] serial number

1

2

3

4

5

6

7

8

9

10

11

12

13

time

load

displacement

out of shape

1

out of shape

2

st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com