Patents

Literature

35 results about "Textile finisher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing.

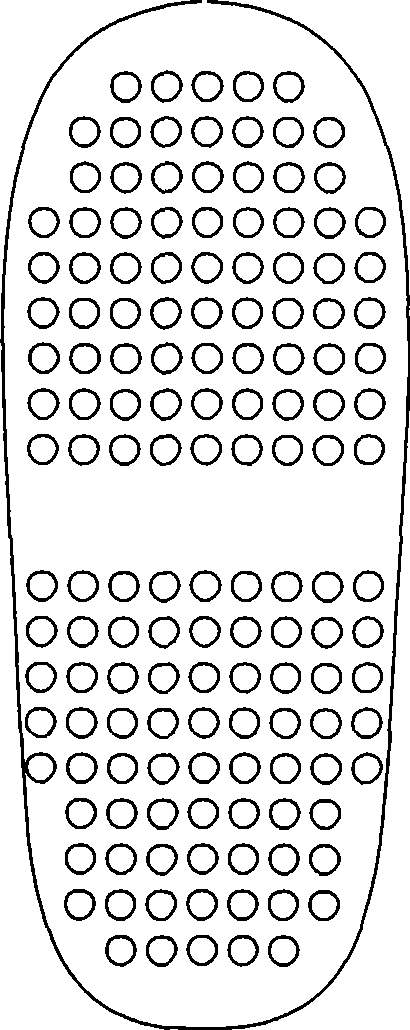

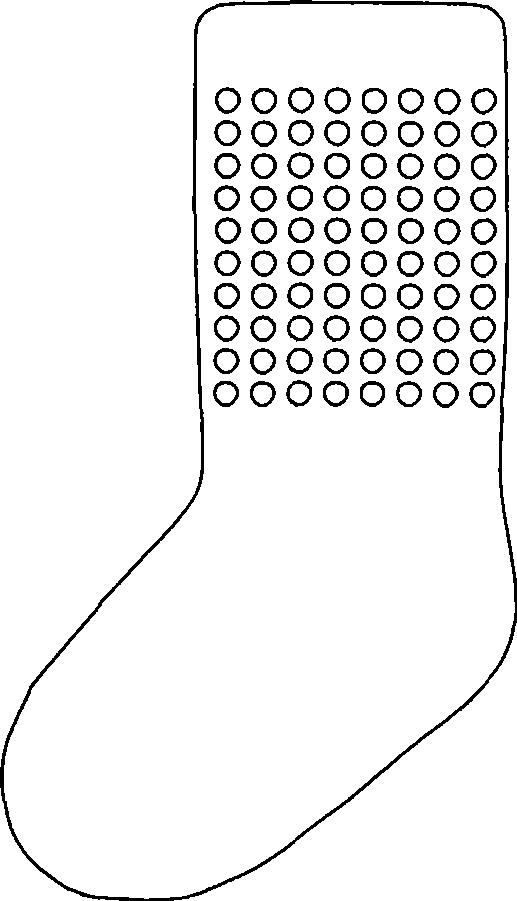

Textile finishing agent with thermal protecting, antibacterial and moisture-keeping functions, and health socks using the same

InactiveCN101476240AStay hydratedAvoid crackingFibre treatmentPanty-hoseTextile technologyHuman body

The invention provides a weaving finishing agent with the functions of emitting far infrared ray, generating air negative ion, resisting bacterium and retaining moisture, which has positive roles to human body health, belonging to the functional textile technology field. The invention further provides the socks applying the weaving finishing agent, which achieves the functions of warming, killing and resisting bacterium, retaining skin moisture, preventing skin seasoning check, promoting blood circulation, promoting metabolism and alleviating fatigue and ache.

Owner:SHENZHEN BAOLI VOGUE TECH

Cation type aqueous full fluorine polyurethane textile finishing agent and preparing method thereof

The invention belongs to the filed of fine chemicals and preparation technology thereof, more particularly relates to a cationoid aqueous perfluorinated polyurethane textile finishing agent and a preparation method thereof. The invention aims at overcoming the problems in the prior art that product stability is poor, the combination between the product and fiber textile with negative charge is poorer and the washability of the textile is poorer, simultaneously overcoming the problem of environment pollution existing in the preparation technology. The aim of the invention is realized as follows: the cationoid aqueous perfluorinated polyurethane textile finishing agent is prepared by the following method which sequentially comprises the following steps of: (1) preparing a tertiary amine type polyurethane prepolymer containing hydrophilic group; (2) preparing perfluorinated alkyl end capping polyurethane; and (3) preparing perfluorinated alkyl end capping quaternary ammonium salt type cation aqueous polyurethane. The invention has the advantages of good water proof property, good stability, good hydrophobic and oleophobic property and environment-friendly and simple and convenient preparation technology.

Owner:SHAANXI UNIV OF SCI & TECH

Textile finishing agents

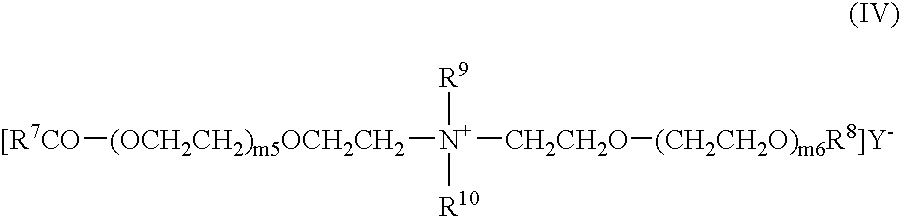

InactiveUS20060258558A1Organic detergent compounding agentsNon-ionic surface-active compoundsFiberYarn

A method for treating fibers, yarns or textiles to improve the sensory effect for a user or weaver of a fabric article. The method treats the fiber, yarns or textiles with an emulsion containing 15-30% by weight of a mixture of waxes having melting points in the range of 35° C. to 60° C. including a lipophilic wax matrix; 10%-20% by weight of emulsifier which are at least one of alkyl or alkenyl oligoglycosides or alkyl ether sulfates, 1%-10% by weight of a crystal regulator which can be partial esters of C12-22 fatty acids with at least one of glycerol, polyglycerol and sorbitan. The mean particle size of the wax crystals is not greater than 6 μm. The emulsion includes water and auxiliaries and additives.

Owner:COGNIS IP MANAGEMENT GMBH

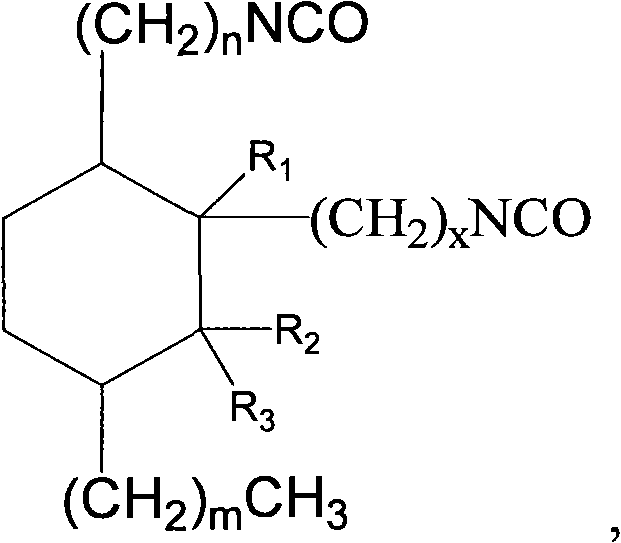

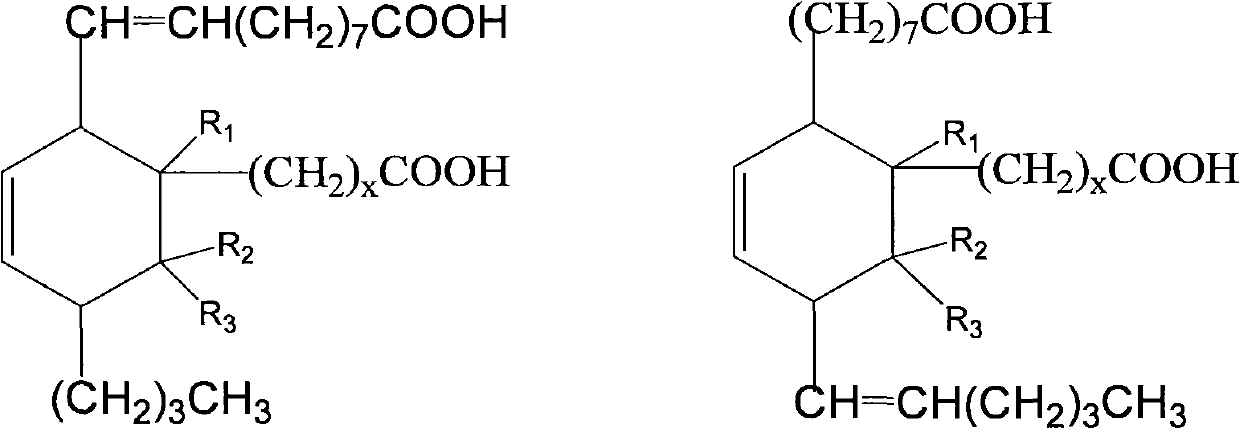

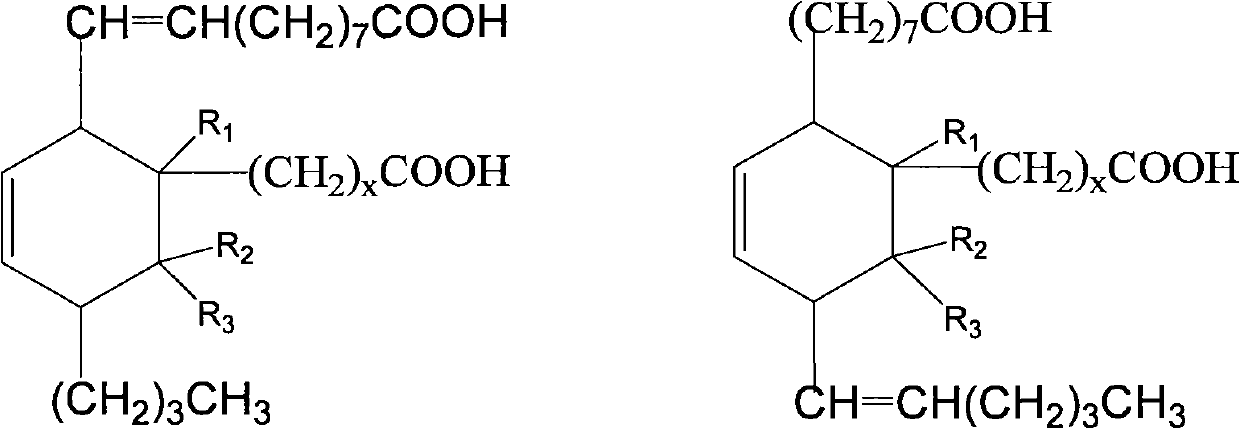

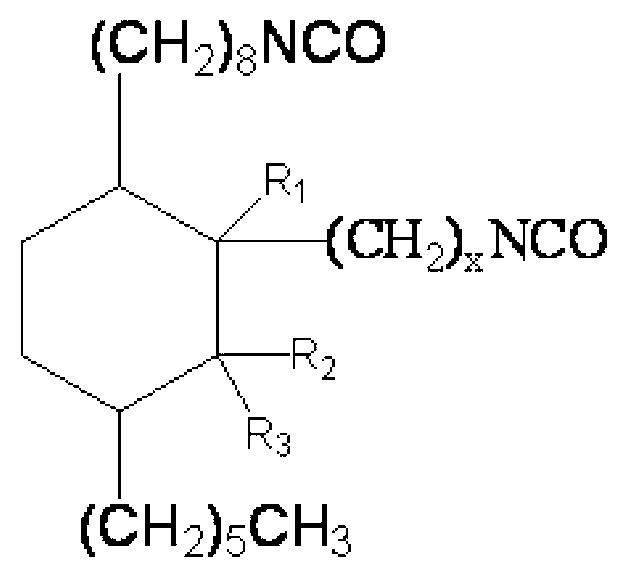

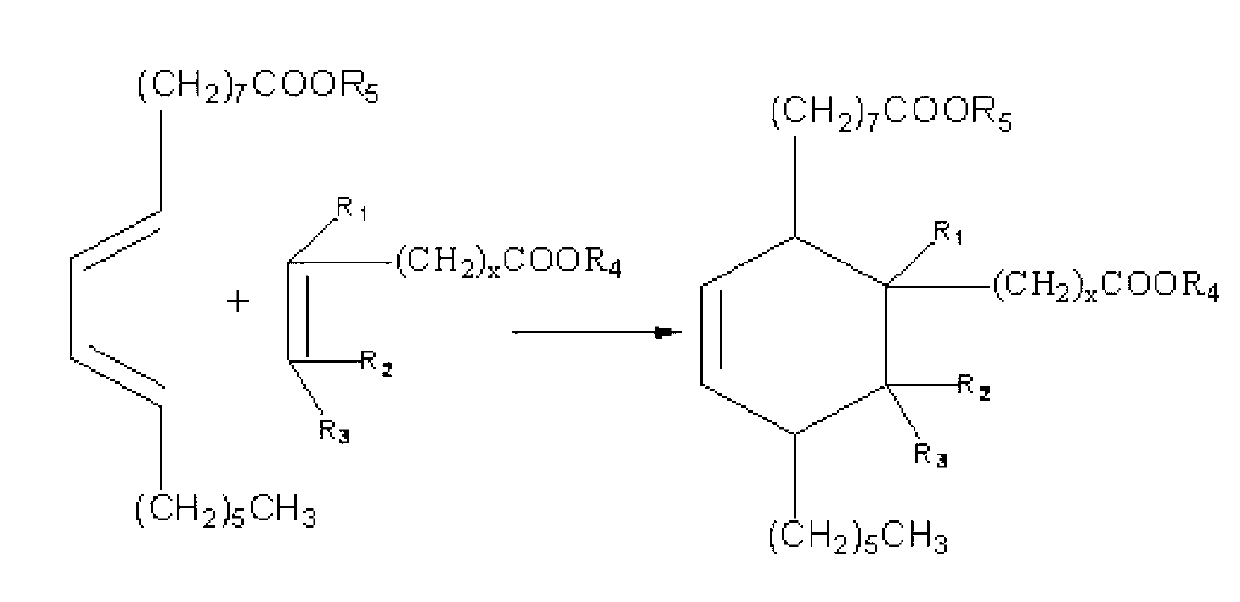

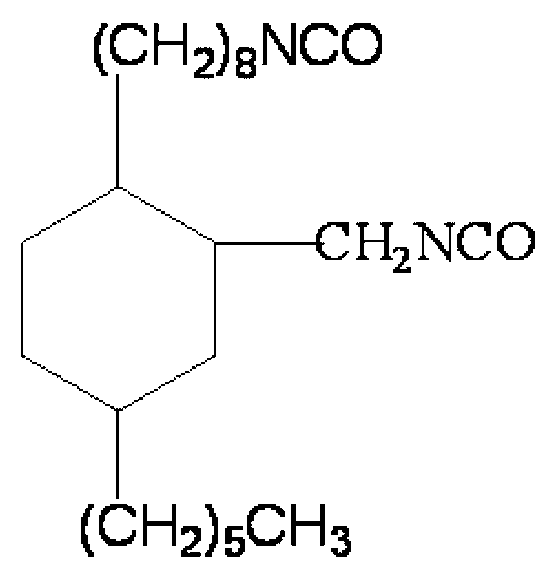

2-octyl-3,4-di(7-diisocyanateheptyl)-1-hexylcyclohexane and its preparation method and use

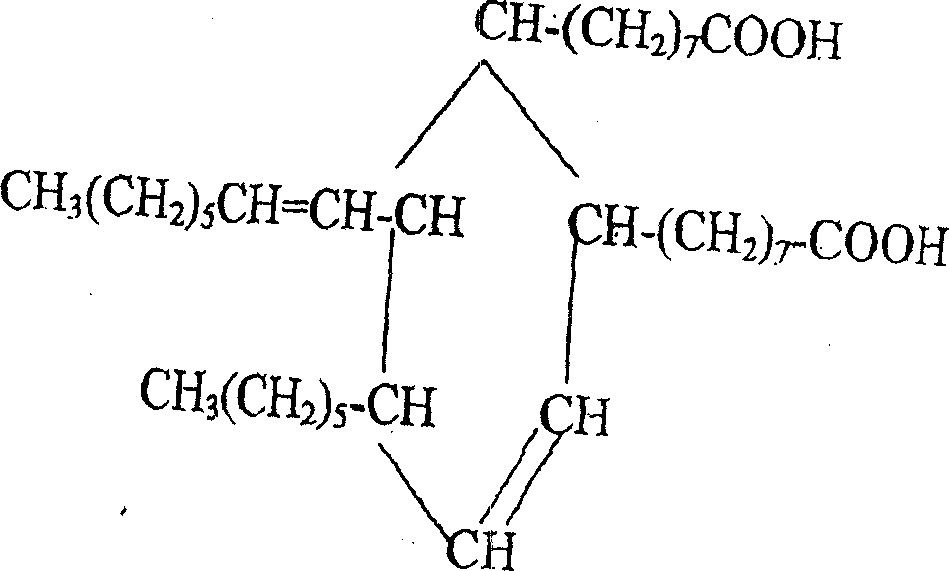

InactiveCN101100448AEasy to industrializeEasy to operatePreparation from carboxylic acid nitrogen analoguesElastomerIsomerization

Production of 2-octyl-3,4-di(7-isocyanate caprylic)-1-hexyl cyclohexane and fatty isocyanate containing it is carried out by hydrogenation catalyzing for dimmer acid between room temperature to 280 deg. C, dewatering for generated saturated dimmer acid, reacting with sulfurous chloride, reacting dimeric acid acyl bromide with sodium azide to generate dimeric acid azide, isomerization decomposing to convert into final product. It can be used to produce polyurethane varnish, elastomer, adhesive, spinning finishing agent and rocket impeller.

Owner:刘林学 +1

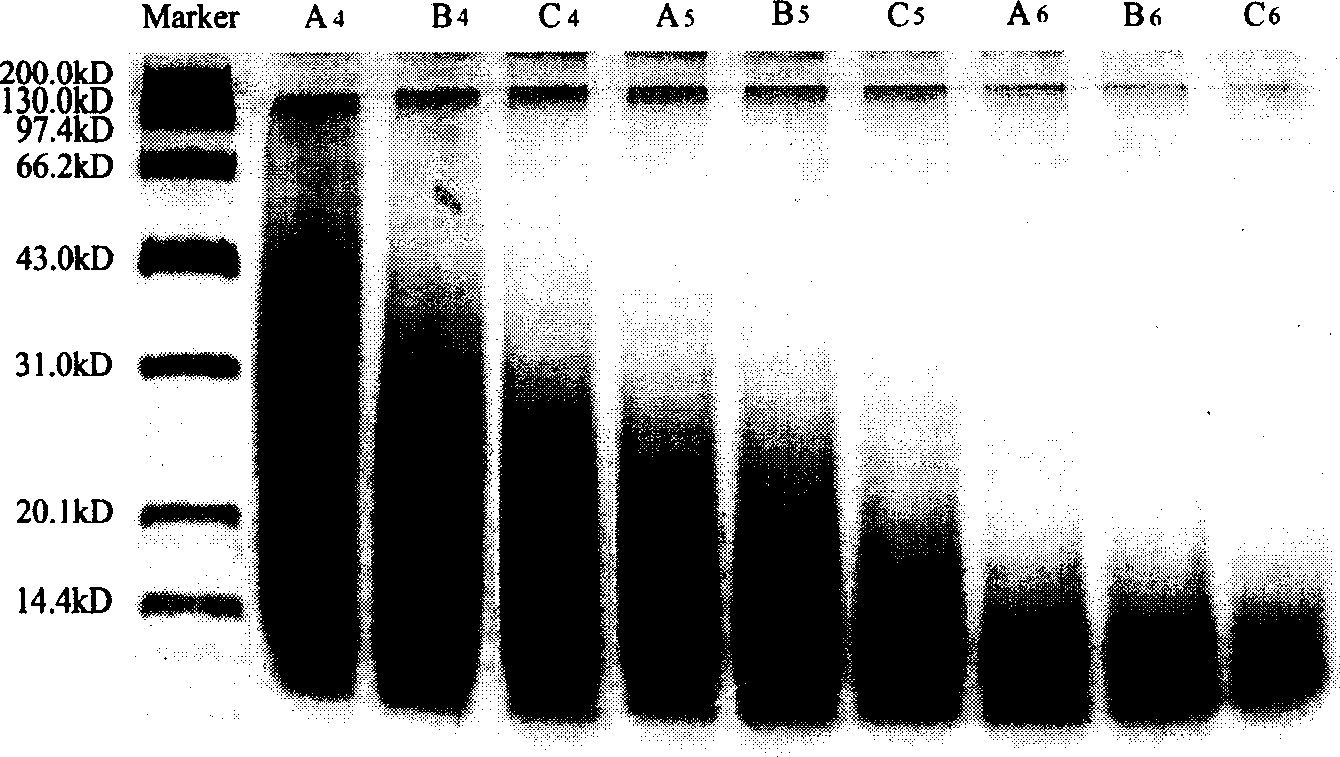

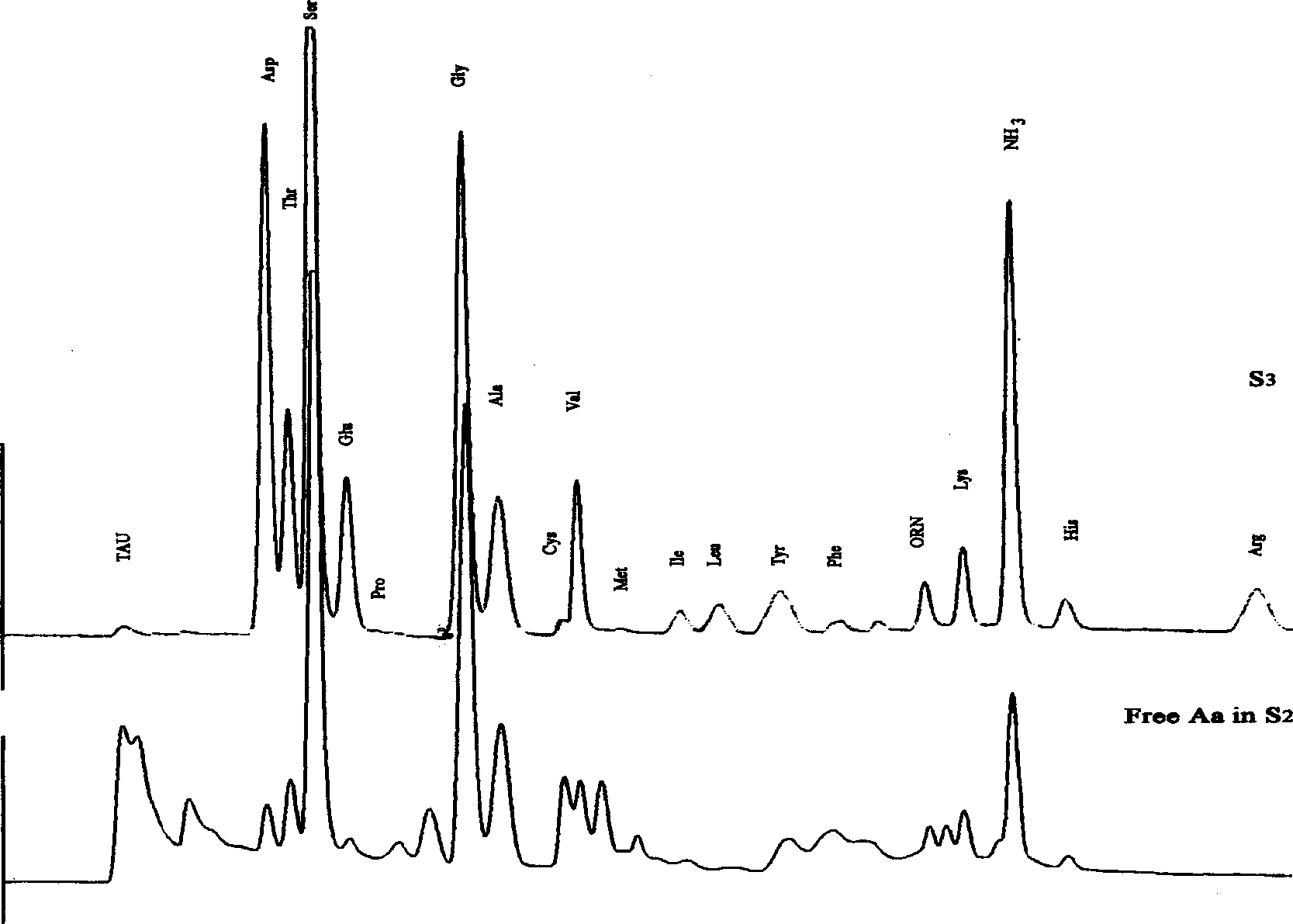

Production method of water soluble sericin

The method for preparing water soluble sericin with different molecular weights by using cocoon as raw material includes the following steps: soaking cleaned cocoon crust and waste silk in water or alkalescency solution, regulating pH value of said solution to 8-12 and making high-temp. high-pressure degrading treatment, regulating temp. or pressure, treatment time and pH value of boiling solution and controlling requirement molecular weight of water soluble sericin so as to prepare water soluble sericin solution or powder. The product can be extensively used in the fields of biological material, textile finishing agent.

Owner:SUZHOU UNIV

Aliphatic diisocyanate and preparation method and purposes thereof

ActiveCN101805270AHigh yieldEasy to operatePreparation from carboxylic acid nitrogen analoguesPolyureas/polyurethane adhesivesElastomerChemical structure

Owner:浙江优创材料科技股份有限公司

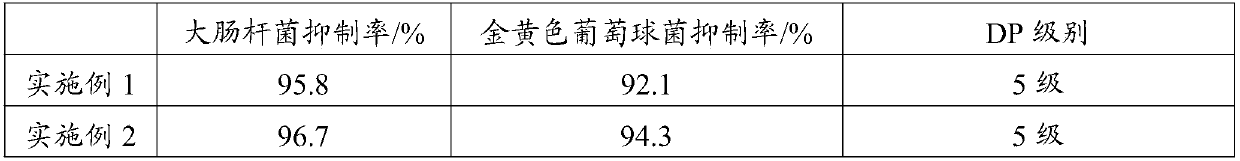

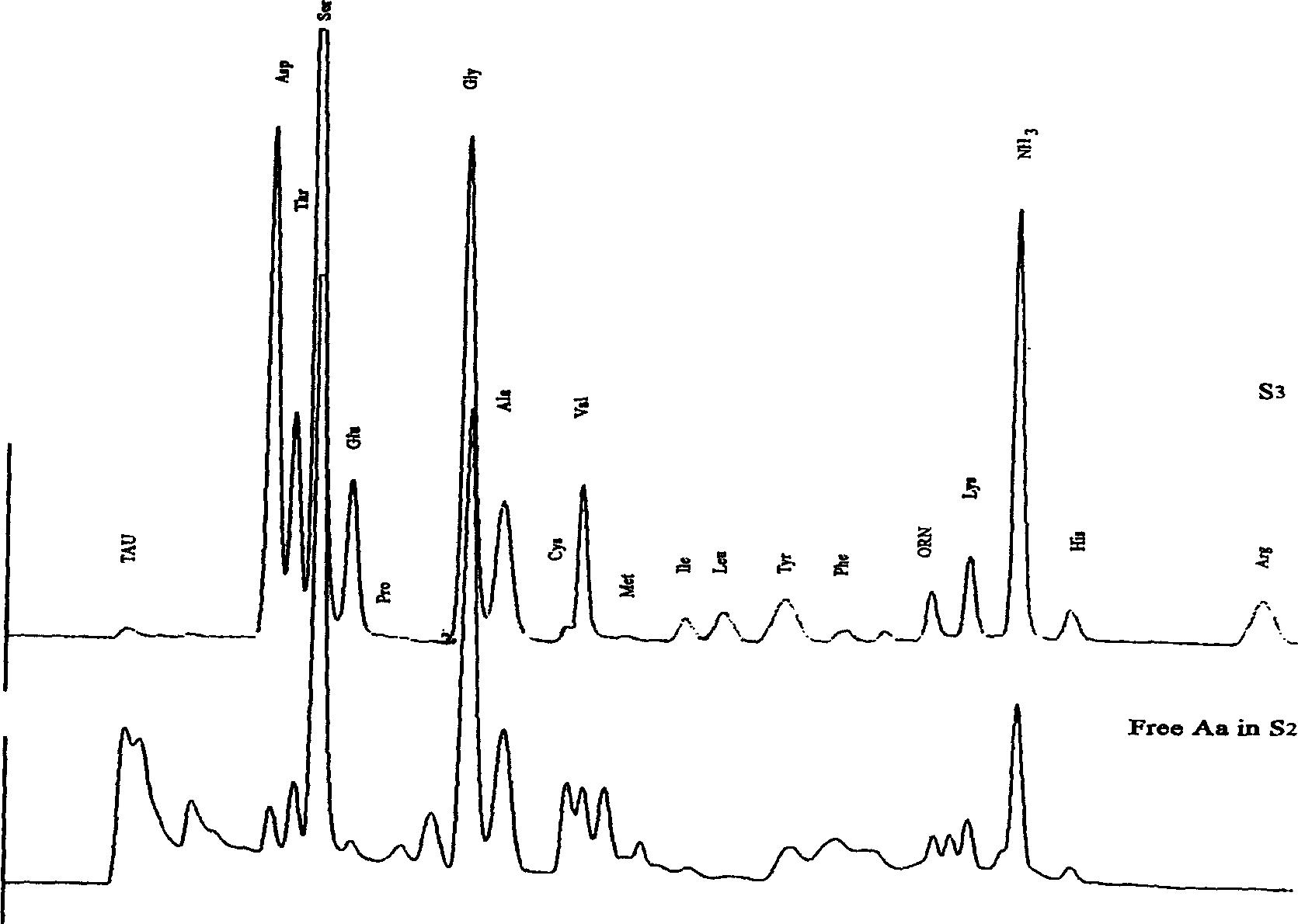

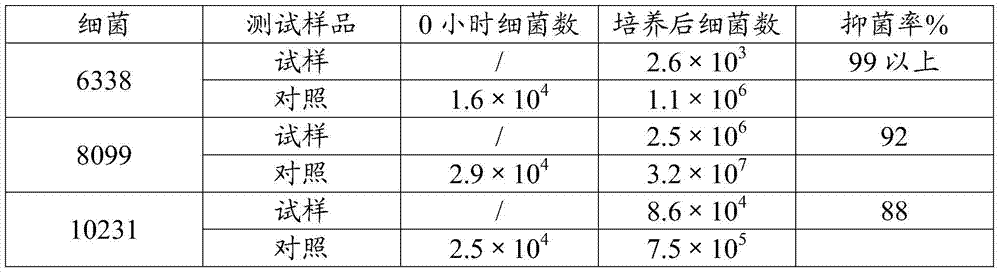

Method for preparing bacteriostatic textile finishing agent from ursolic acid extract

ActiveCN110499644ALow extraction rateRaw materials are easy to obtainBiocideBiochemical fibre treatmentSolubilitySilanes

The invention relates to the field of preservation of textile relics, and discloses a method for preparing a bacteriostatic textile finishing agent from an ursolic acid extract. A dual-phase extraction method and a microwave-assisted extraction method are combined to be used for shortening the extracting time and improving the extraction efficiency. A mixed solution of a (NH4)2SO4 solution and ethyl alcohol is used as an extracting agent, the viscosity is easily reduced, the diffusivity and the solubility of the liquid are improved, and therefore, the content of extracted ursolic acid is increased. The ursolic acid and nanometer zinc oxide are used as a bacteriostatic agent, and the antibacterial activity of a textile is improved; by adding 3 (trimethoxy silane) propyl dimethyl octadecyl ammonium chloride and 3-imino-N-nitrided acetamidocyclic buty amide in the preparation process of the textile finishing agent, the finishing agent can be chemically bonded with cellulosic fibers and can be polycondensated to form a film, and the antibiotic constituents of the finishing agent have the washability.

Owner:ZHEJIANG SCI-TECH UNIV

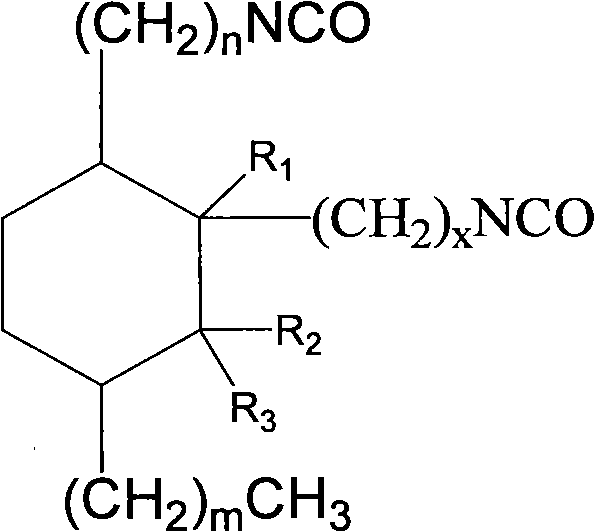

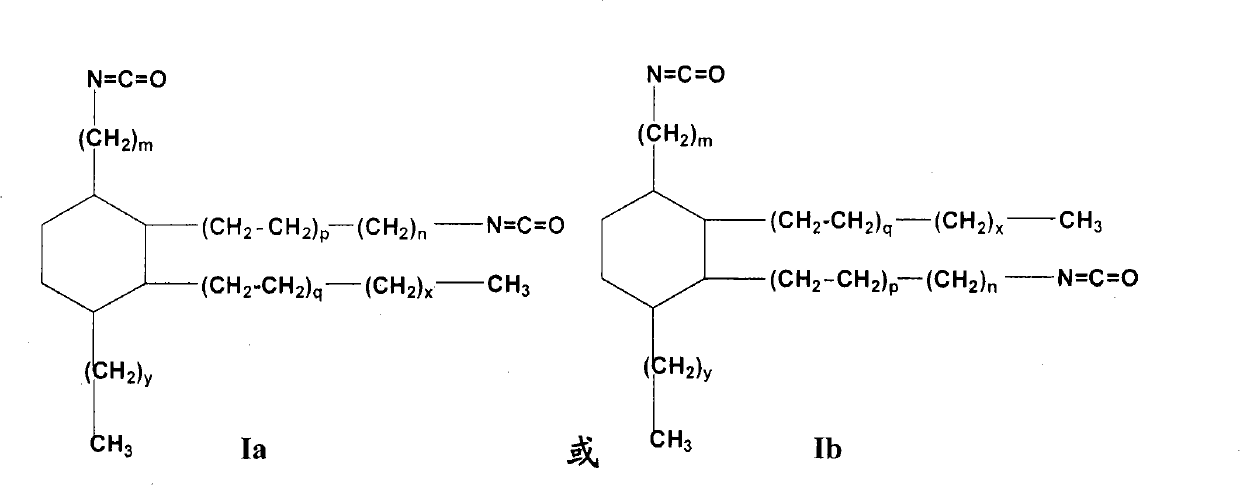

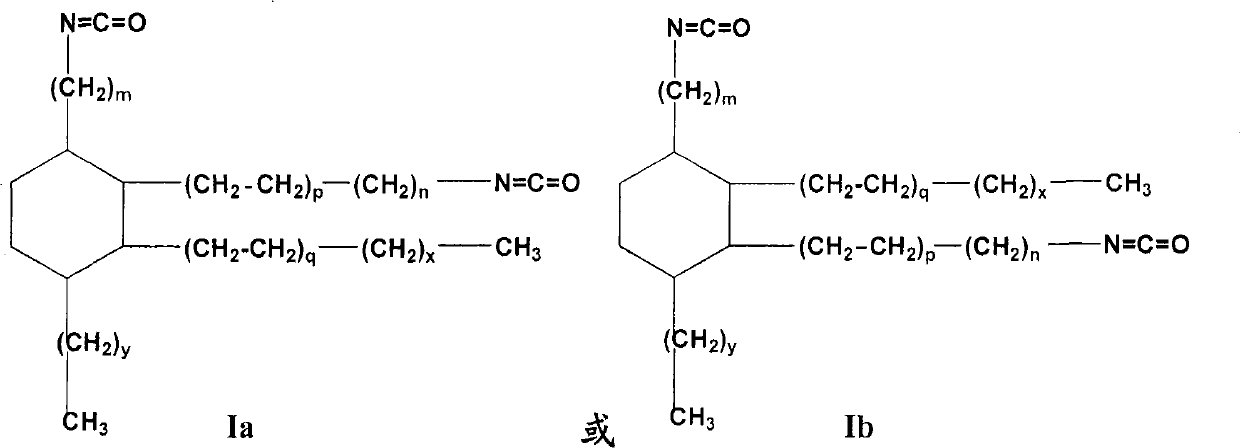

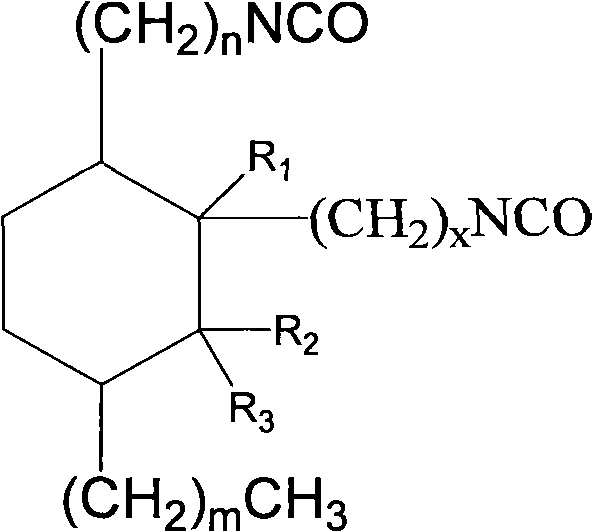

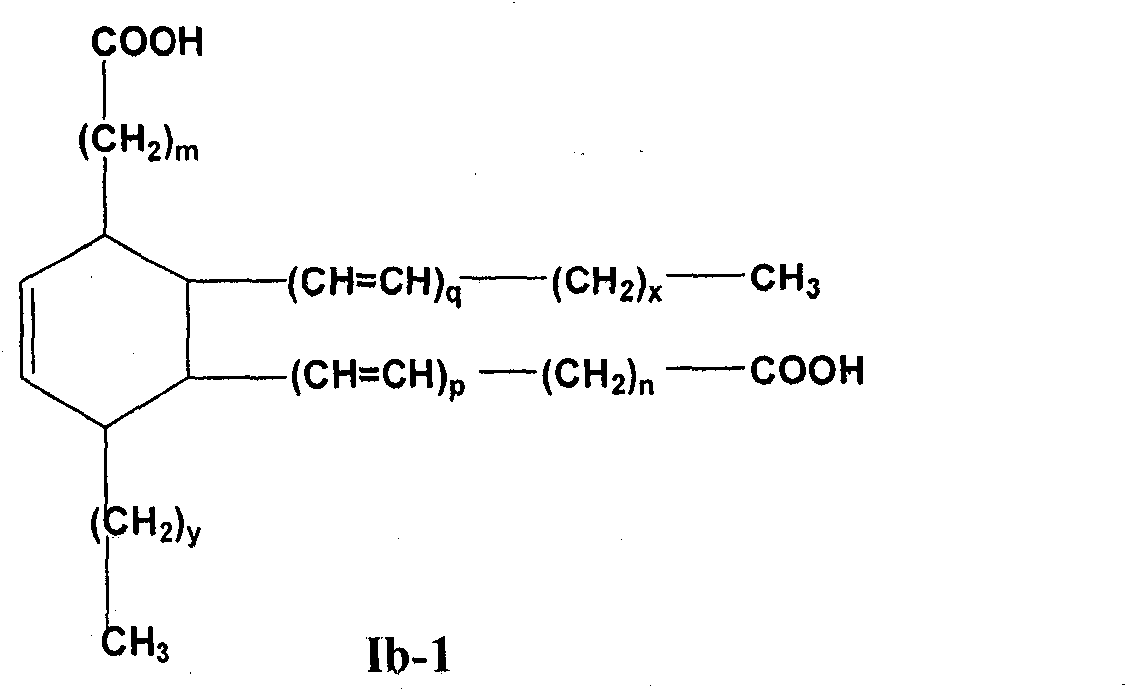

Isocyanate alkyl substituted cyclohexane and preparation method as well as application thereof

ActiveCN101792402AEasy to industrializeEasy to operateIsocyanic acid derivatives preparationOrganic compound preparationElastomerPolymer science

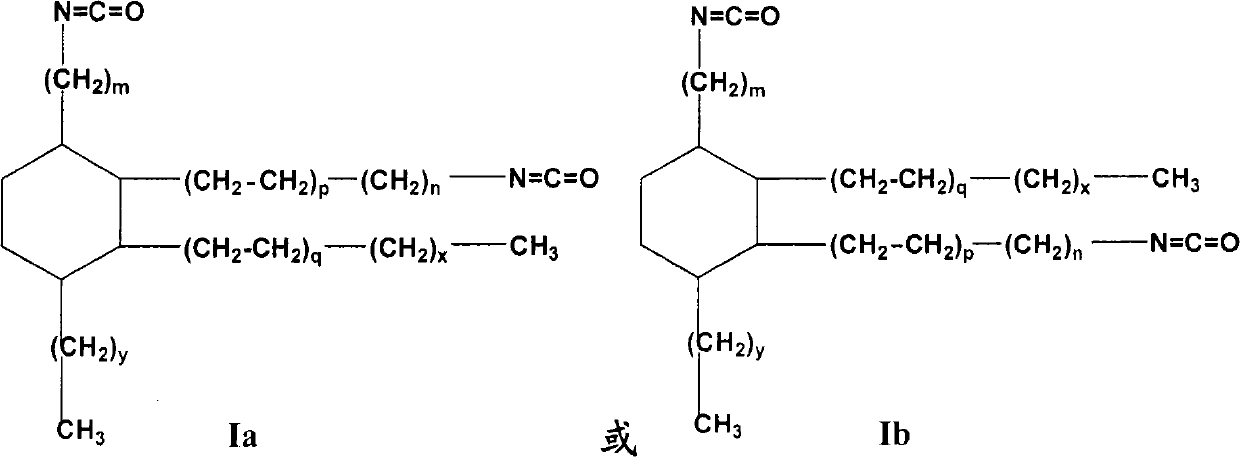

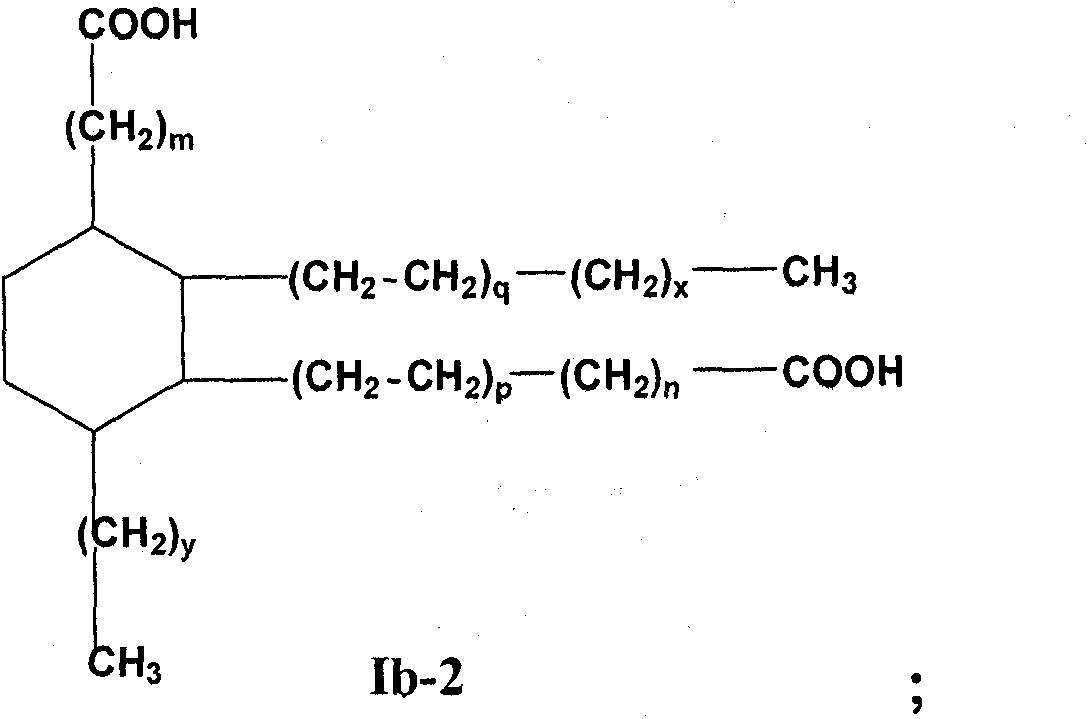

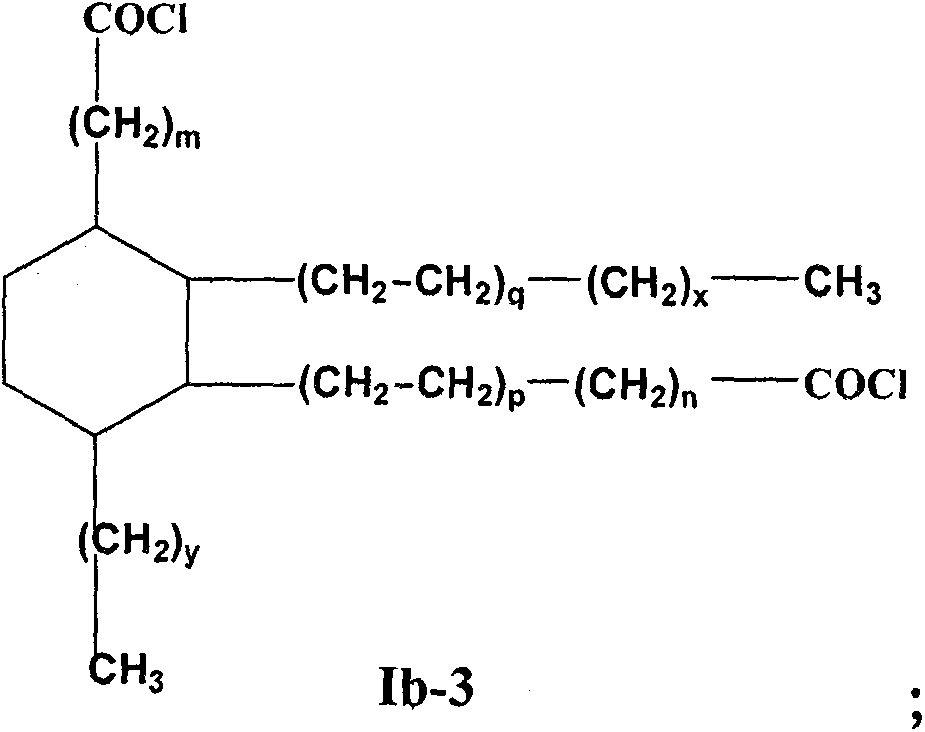

The invention relates to a compound shown in formula Ia or Ib, wherein one of p and q is equal to 0, and the other one of p and q is equal to 1; m and y are respectively equal to integers from 0 to 12 independently, and the sum of m and y is equal to 12; and n and x are respectively equal to integers from 0 to 12 independently, and the sum of n and x is equal to 12. The invention also relates to a preparation method of the compound shown in formula Ia or Ib and application of the compound shown in formula Ia or Ib as a component for producing polyurethane lacquer, paint, elastomers, adhesives, textile finishing agents or rocket propellants.

Owner:浙江优创材料科技股份有限公司

Cation type aqueous full fluorine polyurethane textile finishing agent and preparing method thereof

The invention belongs to the filed of fine chemicals and preparation technology thereof, more particularly relates to a cationoid aqueous perfluorinated polyurethane textile finishing agent and a preparation method thereof. The invention aims at overcoming the problems in the prior art that product stability is poor, the combination between the product and fiber textile with negative charge is poorer and the washability of the textile is poorer, simultaneously overcoming the problem of environment pollution existing in the preparation technology. The aim of the invention is realized as follows: the cationoid aqueous perfluorinated polyurethane textile finishing agent is prepared by the following method which sequentially comprises the following steps of: (1) preparing a tertiary amine type polyurethane prepolymer containing hydrophilic group; (2) preparing perfluorinated alkyl end capping polyurethane; and (3) preparing perfluorinated alkyl end capping quaternary ammonium salt type cation aqueous polyurethane. The invention has the advantages of good water proof property, good stability, good hydrophobic and oleophobic property and environment-friendly and simple and convenient preparation technology.

Owner:SHAANXI UNIV OF SCI & TECH

Special antibacterial finishing agent for textiles and preparation method of special antibacterial finishing agent

InactiveCN106758218AImprove antibacterial propertiesAromaBiochemical fibre treatmentTextile finisherWater soluble

The invention provides a special antibacterial finishing agent for textiles and a preparation method of the special antibacterial finishing agent and belongs to the field of textile auxiliaries. The special antibacterial finishing agent for the textiles is prepared from the raw materials of sodium carboxymethylcellulose, amino silicon oil, pine needle oil, a dandelion extract, a honeysuckle flower extract, peppermint oil, fatty alcohol-polyoxyethylene ether, water soluble wool fat, lauramide sodium sulfovinate, citric acid, cocamidopropyl betaine, nano-zinc oxide, chitosan, lysozyme, ethanol and water. The special antibacterial finishing agent for the textiles, provided by the invention, has the advantages of high antibacterial property, aromatic odor, safety, reliability, no stimulation and no allergic reactions to skins, no potential carcinogenicity, simple preparation process, low raw material cost and convenient use, is green and environment-friendly and is poison-free for people at the application concentration; the special antibacterial finishing agent for the textiles has the function of performing mildew resistant finish on cotton, ramie and chemical fiber; and the finished fabrics have the advantages of facile hand feeling and comfortable sense.

Owner:张发民

Functional fabric and preparation process thereof

ActiveCN112695524AImprove adsorption capacityGuaranteed adsorption effectBiochemical fibre treatmentVegetal fibresPolymer scienceCollagenan

The invention discloses functional fabric and a preparation process thereof, relates to textile processing, and aims at solving the problem that an antibacterial finishing agent and a collagen finishing agent are prone to instability in a padding process, so that the antibacterial effect of textiles is influenced and becomes poor. The technical scheme is as follows: the fabric is obtained by dipping gray fabric in a collagen finishing agent and an antibacterial finishing agent, wherein the collagen finishing agent comprises the following components in percentage by weight: 5-15% of hydrolytic gel, 10-20% of fibroin, 20-35% of glycine, 5-10% of hydroxyproline, 1-5% of fibroin and the balance of water. The mixed antibacterial finishing agent can form a film on the fabric in a padding process through dimethyl diallyl ammonium chloride, the fastness between the antibacterial finishing agent and the gray fabric and between the collagen finishing agent and the gray fabric is improved, the influence of other textile finishing agents on the antibacterial finishing agent in the padding process is reduced, and therefore, the antibacterial functional characteristic of the fabric is improved.

Owner:浙江流庆纺织有限公司

Textile finishing agent and applications of textile finishing agent in preparation of wicking fabrics

ActiveCN109252366AGood moisture permeabilityGood hygroscopicityUltrasonic/sonic fibre treatmentMoisture permeabilityTextile finisher

The invention discloses a textile finishing agent and applications of the textile finishing agent in preparation of wicking fabrics, wherein the textile finishing agent comprises the following raw materials by weight: 10-20 parts of a chitosan oligosaccharide solution, 0.2-1.0 part of a penetrant, 1-3 parts of a moisture wicking finishing agent, and 100-140 parts of water. According to the presentinvention, the textile finishing agent can carry out post-finishing on the fabric so as to effectively improve the quick-drying wicking property, the moisture permeability and the moisture absorptionof the fabric.

Owner:吴江市新虹利纺织品有限公司

A kind of fiber dyeing and deepening agent and preparation thereof

The invention relates to the technical field of a textile finishing agent, and concretely discloses a fiber dyeing deepening agent. The textile finishing agent is prepared from the following formula raw materials in percentage by mass: 5.0.0 to 10.0 percent of emulsifiers, 10.0 to 20.0 percent of aliphatic amine, 25.0 to 35.0 percent of aliphatic amine derivatives, 3.0 percent of acid, 5.0 to 8.0 percent of aliphatic alcohol, 3.0 to 5.0 percent of urea and the balance deionized water. The fiber dyeing deepening agent has the advantages that the coloring effect on spandex (lycra) and nylon is extremely good; no allergy, no teratogenesis, no mutagenesis and no carcinogenesis are caused; no toxic and side effects are caused on the human body; the energy is saved; the environment is protected.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

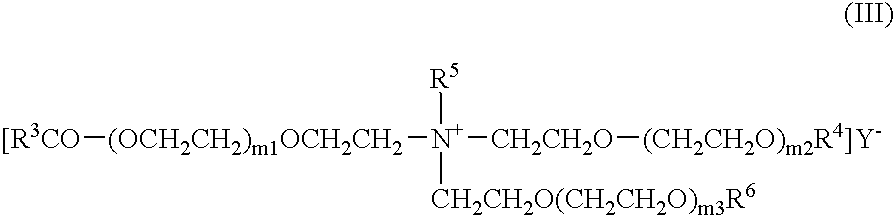

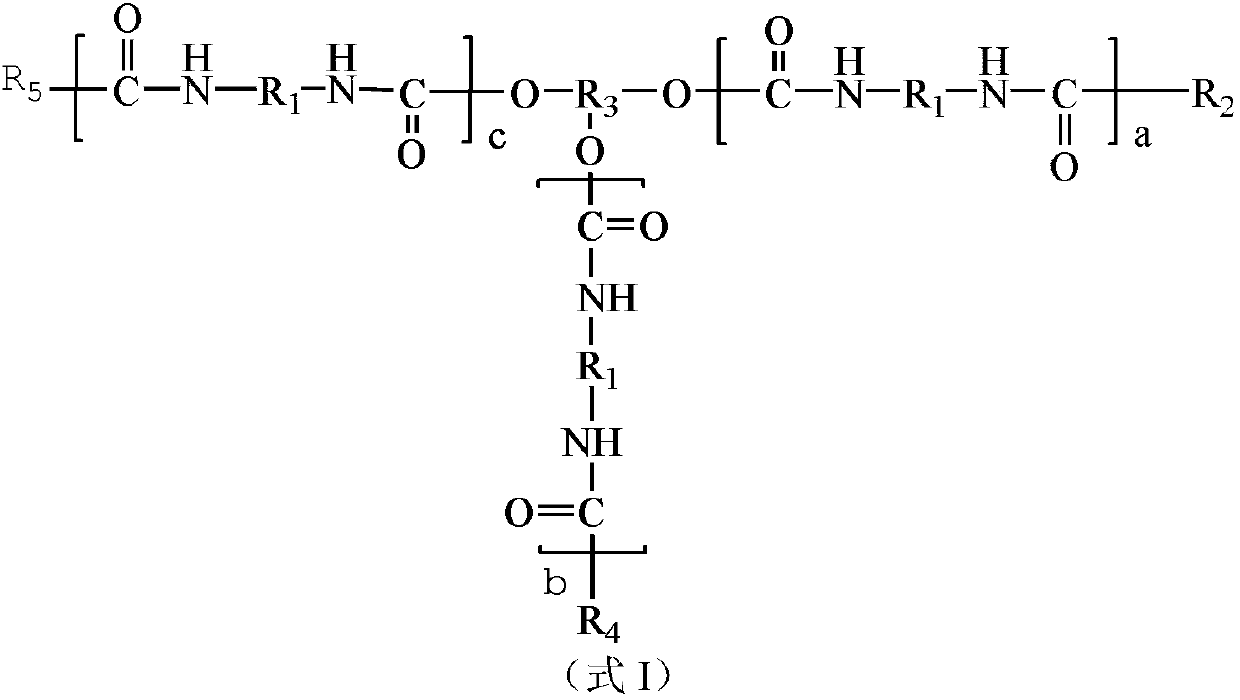

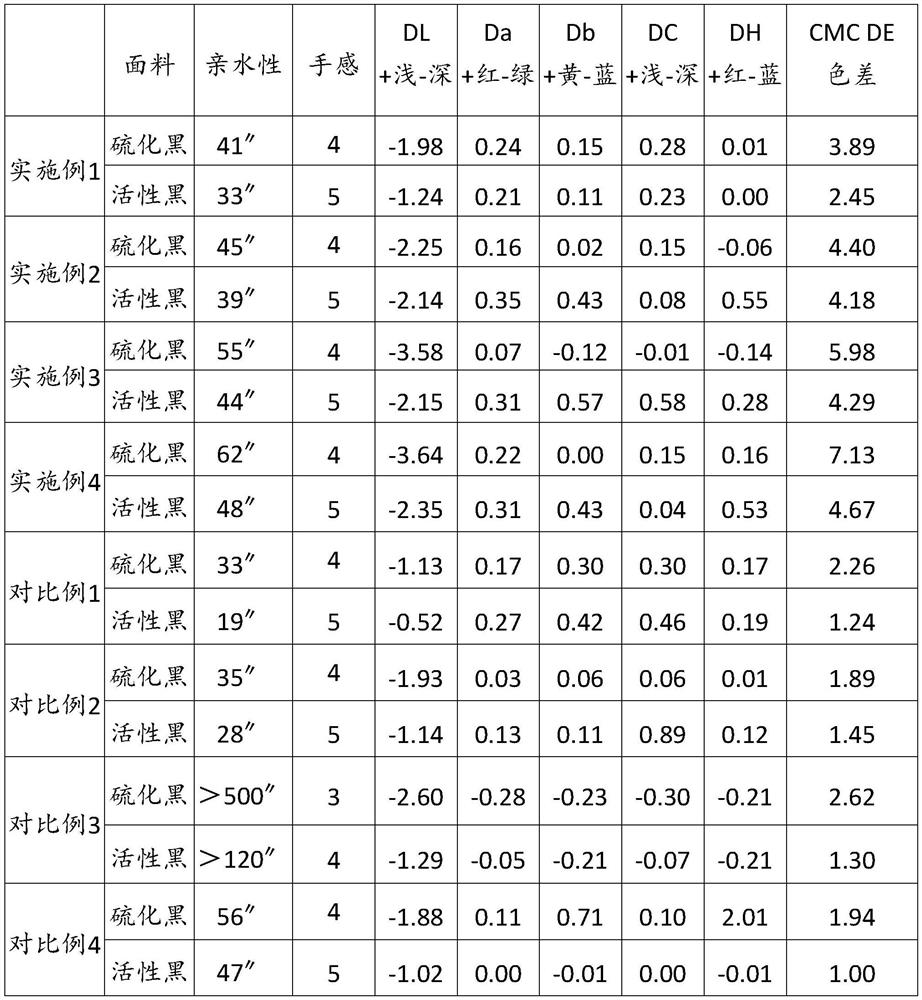

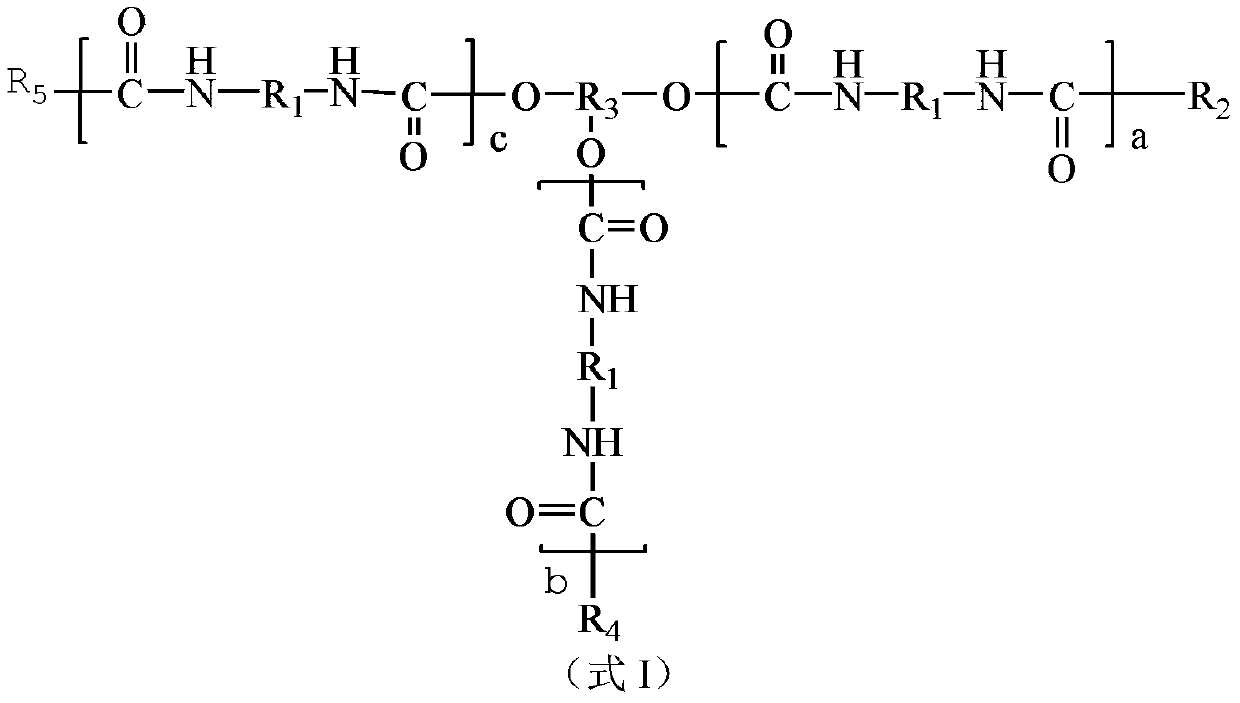

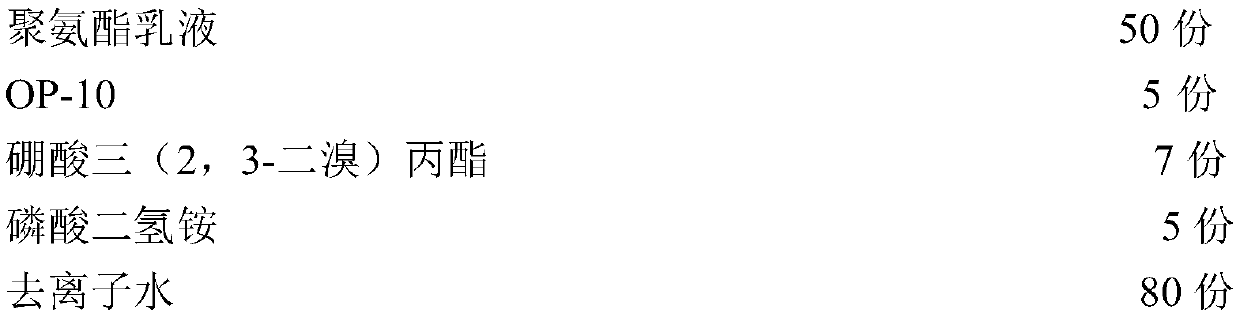

Laundering-resisting flame-retarding synergist for textiles as well as preparation method and application thereof

ActiveCN107759763AReduce the effect of water repellencyReduce the impactHeat resistant fibresLiquid repellent fibresOrganic acidAlcohol

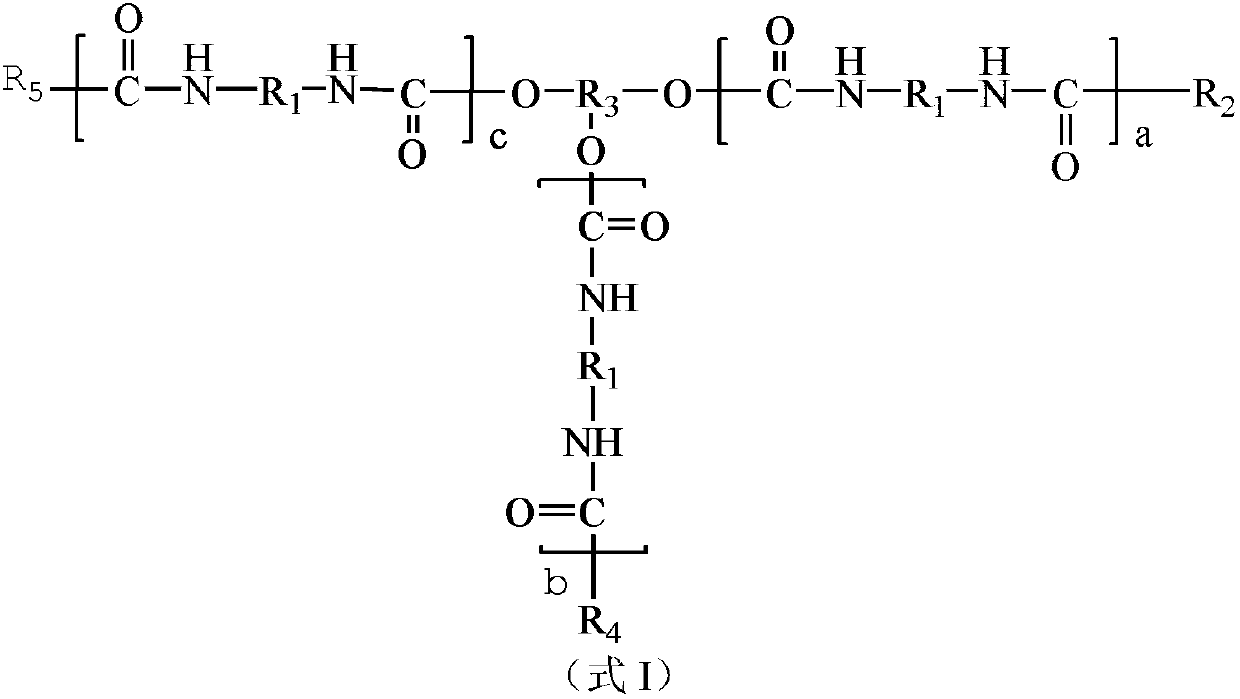

The invention discloses a laundering-resisting and flame-retarding synergist for textiles as well as a preparation method and application thereof. The flame-retarding synergist is prepared from the following substances in parts by mass: 40 to 60 parts of a polyurethane flame retardant, 3 to 10 parts of an emulsifier, 5 to 15 parts of an organic acid ester type flame retardant, 4 to 8 parts of ammonium dihydrogen phosphate and 80 parts of de-ionized water, wherein a structural general formula of the polyurethane flame retardant is shown as formula I, and a, b and c are arbitrary integers from 1to 4; R1 is a residue of diisocyanate; R2 is a residue of halogen-containing alcohol; R3 is a residue of polyol; R4 is a residue of methoxypolyethylene glycols; and R5 is a residue of an end cappingagent. The laundering-resisting and flame-retarding synergist for the textiles, provided by the invention, is mainly applied to functional finishing of the textiles and can be used for synergizing thelaundering resistance and the flame-retarding performance of a textile finishing agent; and the laundering-resisting and flame-retarding synergist has the advantages of cheap and easy-to-obtain raw materials, simple preparation technology and safety and environment protection. The formula I is shown in the description.

Owner:BEIJING CTA TEX CHEM

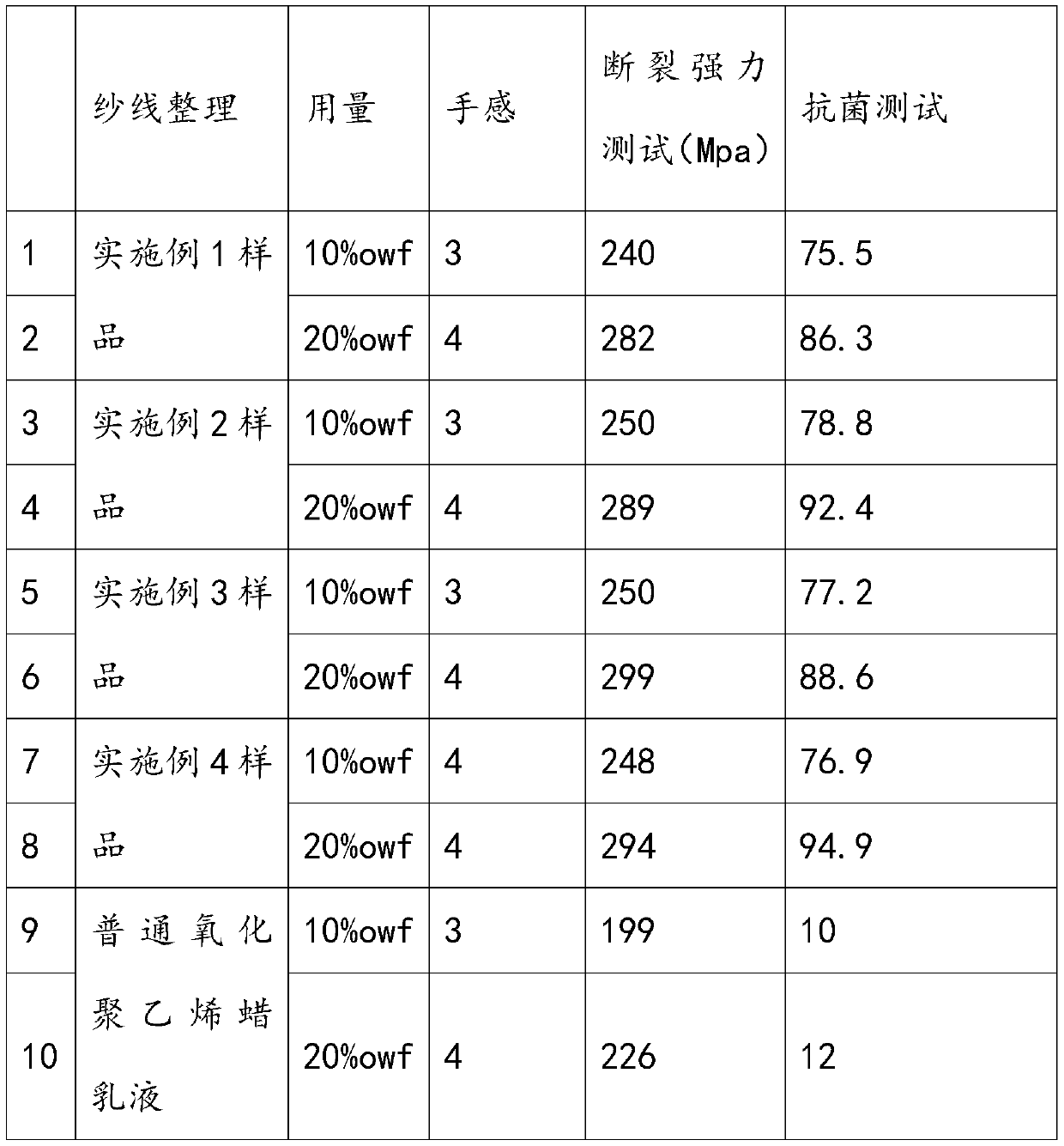

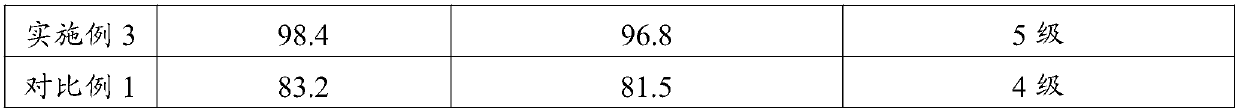

Graphene modified oxidized polyethlene wax emulsion and preparing method thereof

The invention relates to a graphene modified oxidized polyethlene wax emulsion and a preparing method thereof, and belongs to the technical field of chemical emulsion synthesis and textile processing.The graphene modified oxidized polyethlene wax emulsion is prepared from 0.1-50% of graphene, 0.1-50% of an emulsifier, 0.1-50% of oxidized polyethlene wax, 0.1-50% of a co-emulsifier, 30-99% of water and 0.01-2% of a neutralizer. The preparing method comprises the following steps of adding the graphene, the emulsifier, the oxidized polyethlene wax, the co-emulsifier, the water and the neutralizer into a high-pressure emulsification kettle; under the protection of nitrogen, conducting stirring, and gradually raising the temperature to 10-130 DEG C; carrying out an emulsification reaction, wherein the reaction continues for 20-280 min; taking out a sample, and cooling to 30-50 DEG C. According to the graphene modified oxidized polyethlene wax emulsion and the preparing method thereof, theperformance of the graphene and the performance of the oxidized polyethlene wax emulsion complement each other, a textile finishing agent with stable properties and application processes is obtained and directly used as a textile processing auxiliary, and the purposes of avoiding environmental pollution caused by solvents and improving various properties are achieved.

Owner:上海矽联新材料科技有限公司

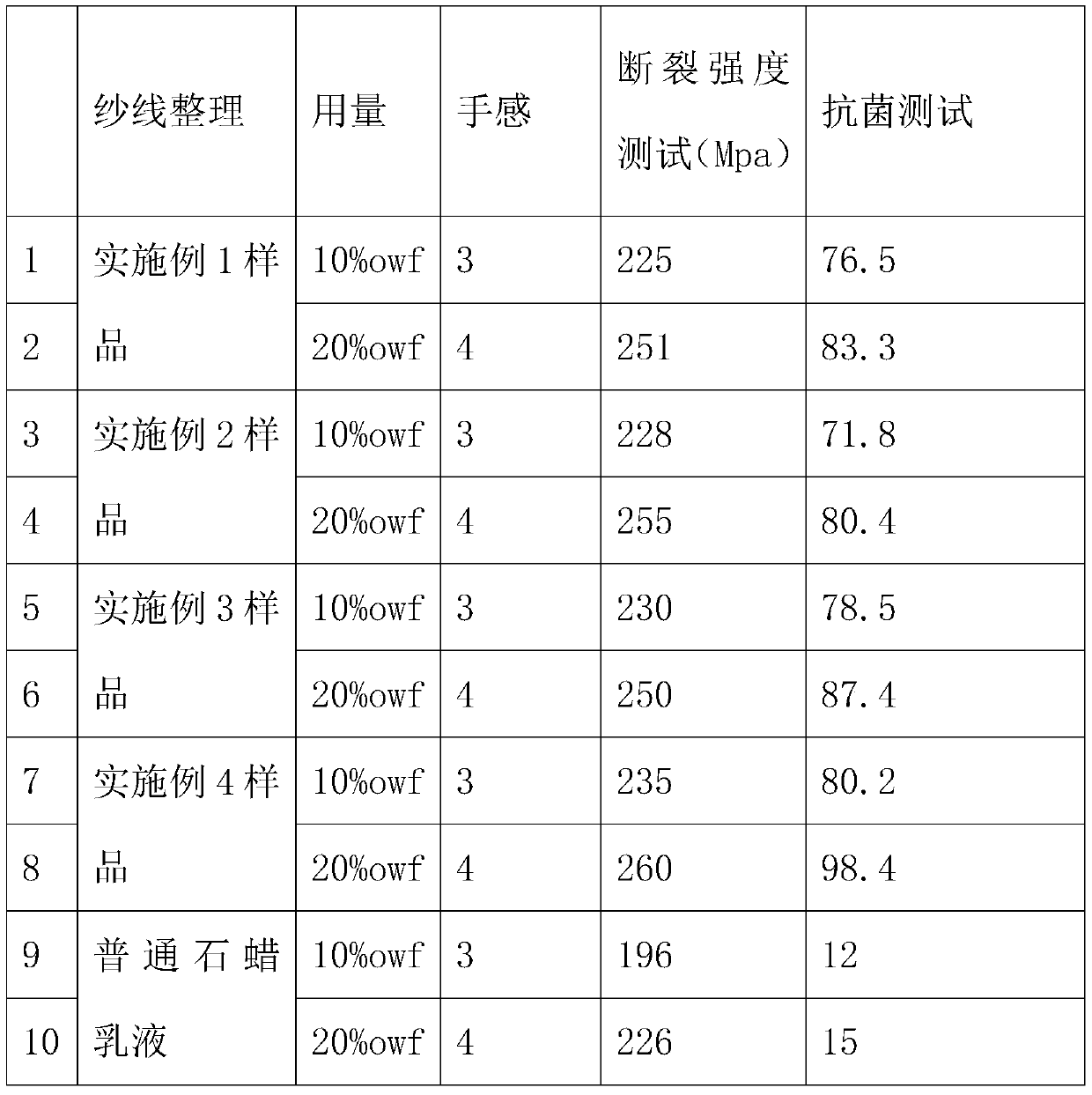

Graphene modified wax emulsion and preparation method thereof

InactiveCN109750494AImprove the lubrication effectHigh yarn strengthVegetal fibresProcedure AgentsEmulsion

The invention relates to a graphene modified wax emulsion and a preparation method thereof, and belongs to the technical fields of chemical emulsion synthesis and textile processing. The graphene modified wax emulsion is prepared from the components in percentage by weight: 0.1-50% of graphene, 1-50% of an emulsifier, 1-50% of wax, 1-50% a co-emulsifier and 30-99% of water. The preparation methodcomprises the following steps: the graphene, the emulsifier, the wax, the co-emulsifier and the water are sequentially added into an emulsification kettle; nitrogen is input from a nitrogen guiding-inpipe, under protection of the nitrogen, a stirrer is started, and the mixture is stirred and gradually heated to 10-100 DEG C; an emulsification reaction is conducted for 10-240 minutes; a sample istaken out and cooled to 40 DEG C or below; and the particle size of the sample is measured, and the sample with the particle size being within 0.5-2 [mu]m is qualified, and discharged. The propertiesof the graphene and a wax emulsion are made to be complementary, thus a textile finishing agent with the stable performance and application process is obtained to be directly used as a textile processing assistant, and the purposes of avoiding pollution of solvents to the environment and improving various properties are achieved.

Owner:上海矽联新材料科技有限公司

Preparation method of environment-friendly ironing-free antibacterial finishing agent for wool fabrics

InactiveCN107780214AEasy to buyReduce energy consumptionBiochemical fibre treatmentAnimal fibresEnvironmental resistancePolyethylene glycol

A preparation method of environment-friendly ironing-free antibacterial finishing agent for wool fabrics belongs to the field of textile finishing agents and includes the steps of: 1) performing a reaction to chitin with diluted hydrochloric acid (15 wt%); 2) adding octyl phenol polyoxyethylene ether, polyethylene glycol and phthalic anhydride, and increasing temperature and performing the reaction continuously; 3) crushing fructus nelumbinis and placing the fructus nelumbinis in an alcohol water solution (60 wt%) to perform stirring extraction, and then performing centrifugal separation and collecting a supernatant; 4) adding the supernatant to the mixture after the heating reaction, adding ironing-free resin FR-E and tartaric acid, and stirring the components in a stirring machine to prepare the environment-friendly ironing-free antibacterial finishing agent. The preparation method employs easy-to-purchase, safe and environment-friendly raw materials, is simple and is low in energy consumption. A fabric processed with the finishing agent has excellent ironing-free and antibacterial performances. The product is an environment-friendly finishing agent which has excellent promotingvalue.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Graphene-modified maleic-anhydride polyethylene wax emulsion and preparing method thereof

InactiveCN109868651AImprove the lubrication effectHigh yarn strengthBiochemical fibre treatmentProcedure AgentsEmulsion

The invention relates to a graphene-modified maleic-anhydride polyethylene wax emulsion and a preparing method thereof, and belongs to the technical field of chemical emulsion synthesis and spinning processing. The graphene-modified maleic-anhydride polyethylene wax emulsion is prepared from 0.1%-50% of graphene, 0.1%-50% of an emulsifying agent, 0.1%-50% of maleic-anhydride polyethylene wax, 0.1%-50% of an auxiliary emulsifying agent, 30%-99% of water and 0.01%-2% of a neutralizing agent. The preparing method includes the following steps that the graphene, the emulsifying agent, the maleic-anhydride polyethylene wax, the auxiliary emulsifying agent, the water and the neutralizing agent are added into an emulsifying kettle; under production nitrogen, the mixture is stirred and heated to 10DEG C to 120 DEG C; an emulsion reaction is conducted for 20 minutes to 220 minutes; samples are taken out, and are cooled to 45 DEG C or below; discharging is conducted. According to the graphene-modified maleic-anhydride polyethylene wax emulsion and the preparing method thereof, the property of graphene and the property of the maleic-anhydride polyethylene wax emulsion are complementary, a spinning finishing agent with the stable property and application technology is obtained, and directly serves as a spinning processing aid, and the aims that pollution of a solvent to the environment isavoided, and various properties are improved are achieved.

Owner:上海矽联新材料科技有限公司

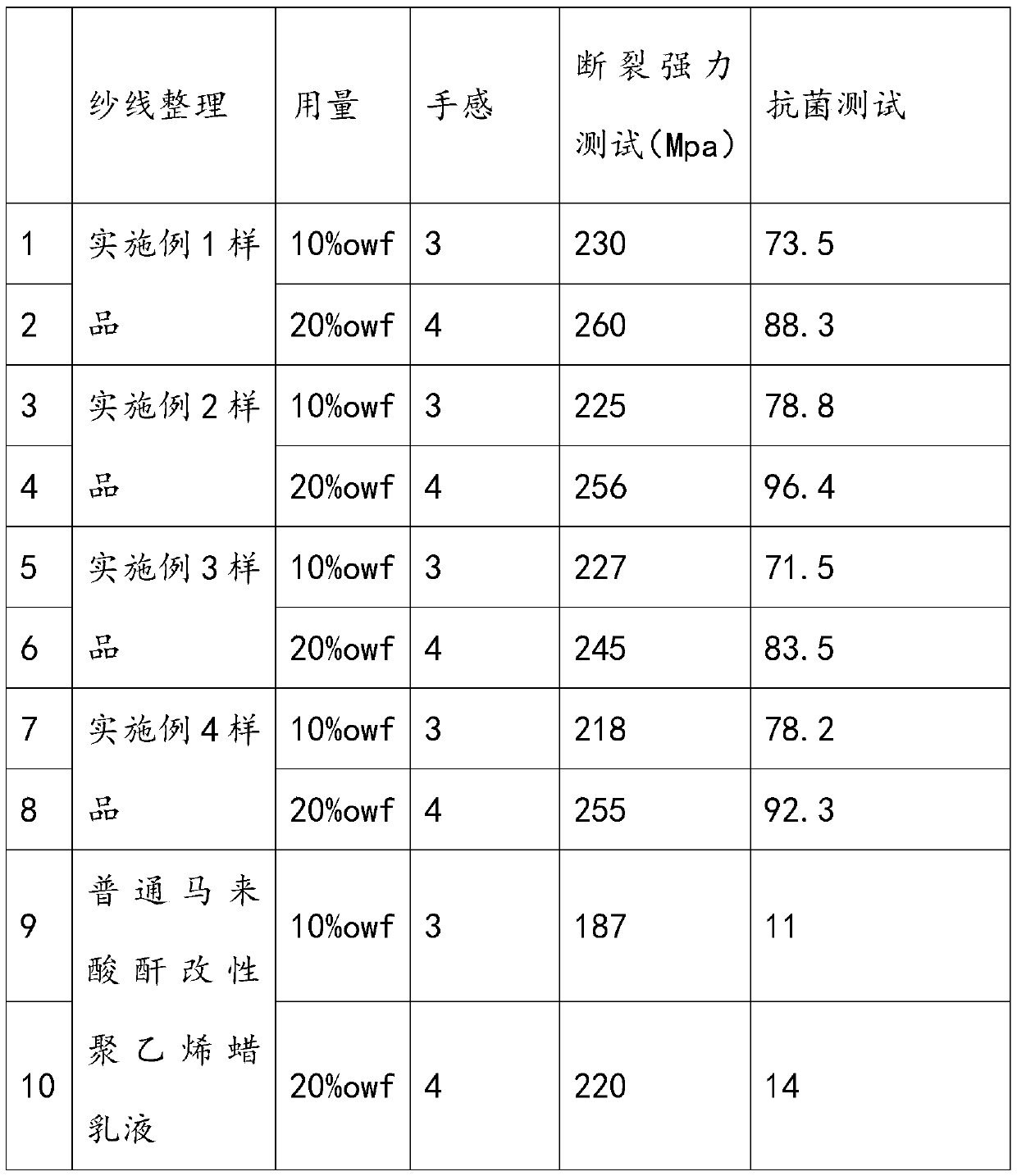

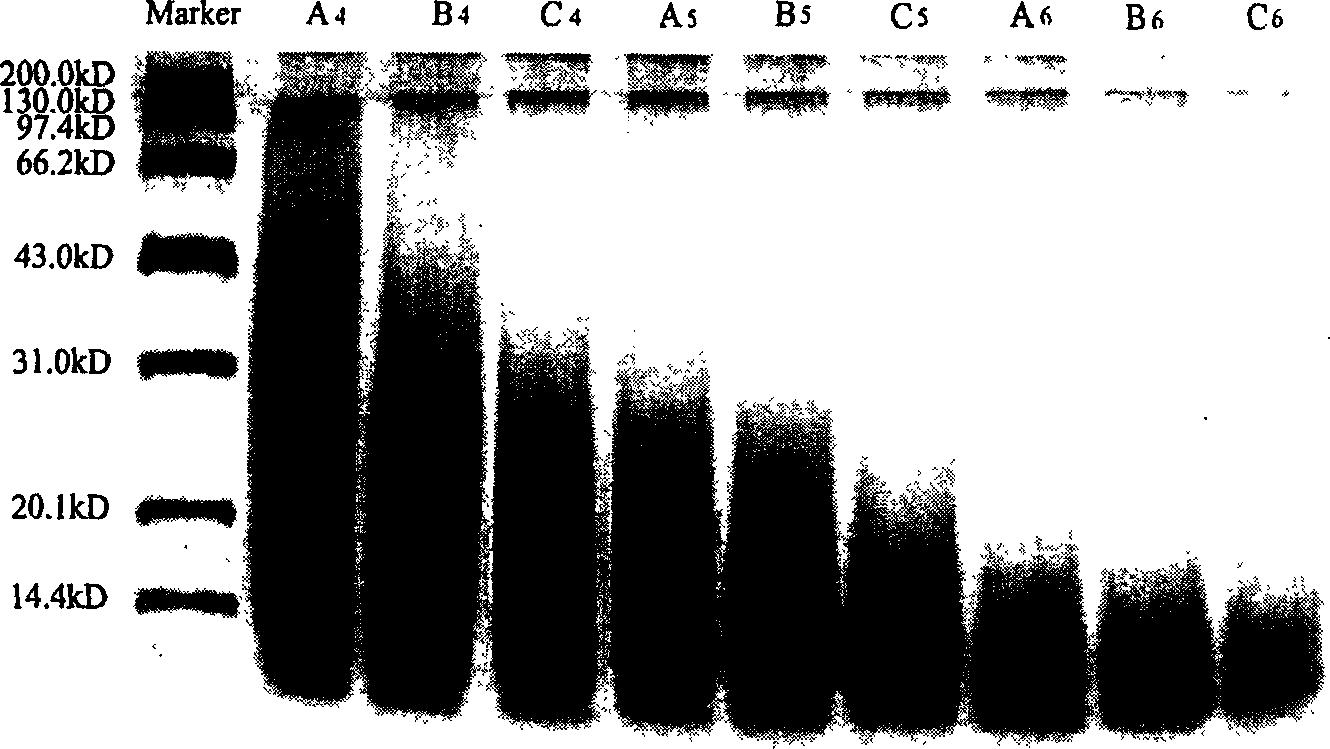

Production method of water soluble sericin

The invention relates to a method for producing water-soluble sericin proteins with different molecular weights by using silkworm cocoons as raw materials. The cleaned cocoon shells, waste silk, etc. are immersed in water or slightly alkaline solution, and after high temperature and high pressure degumming treatment, an insoluble sericin solution is obtained, and the pH value of the solution is adjusted to 8-12, and then the second High temperature and high pressure degradation treatment, by adjusting the process conditions such as temperature or pressure during degradation treatment, treatment time, pH range of degumming solution, etc., to control the molecular weight of water-soluble sericin required to achieve, so as to prepare easily water-soluble silk for different purposes Colloid solution or powder, used in biomaterials, textile finishing agents, health care products, cosmetics, polymer synthetic materials and other fields.

Owner:SUZHOU UNIV

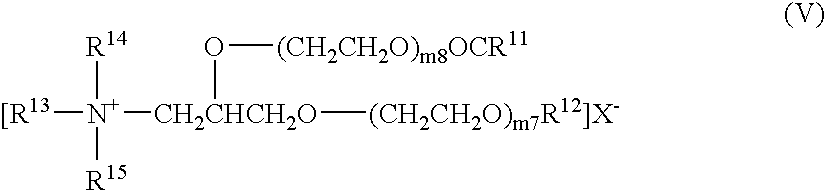

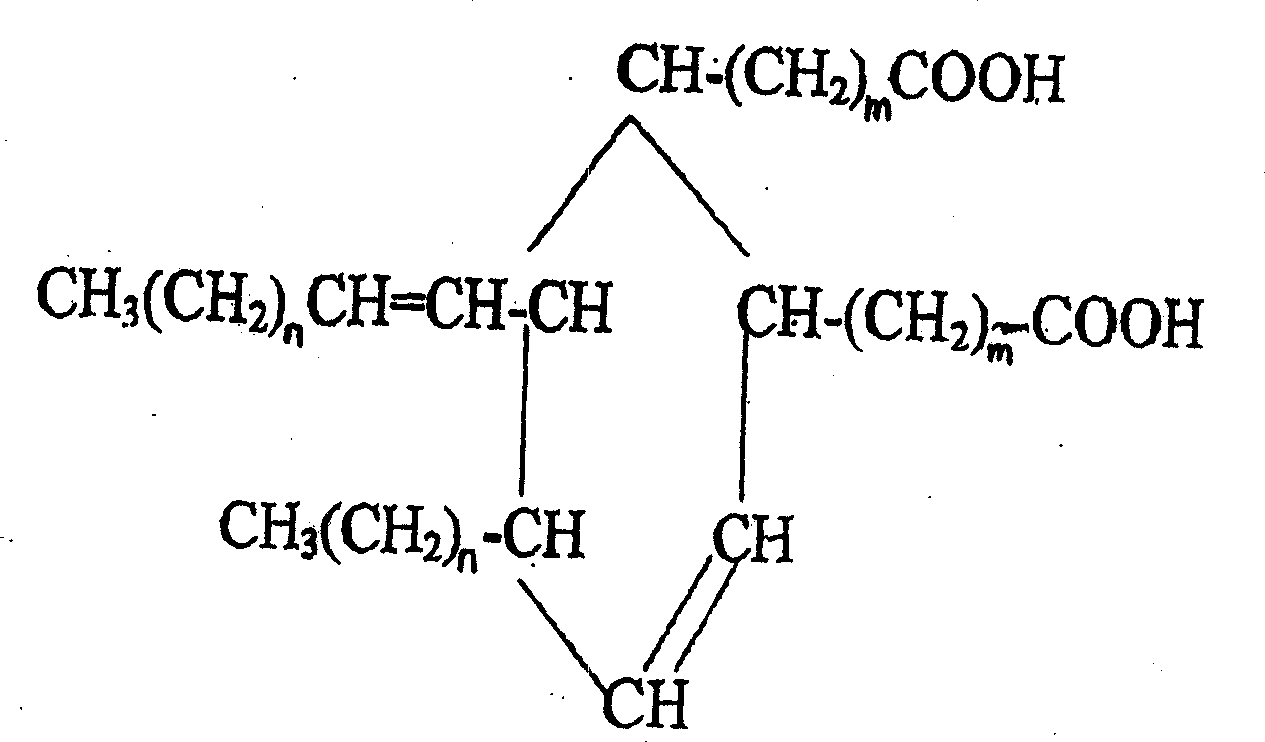

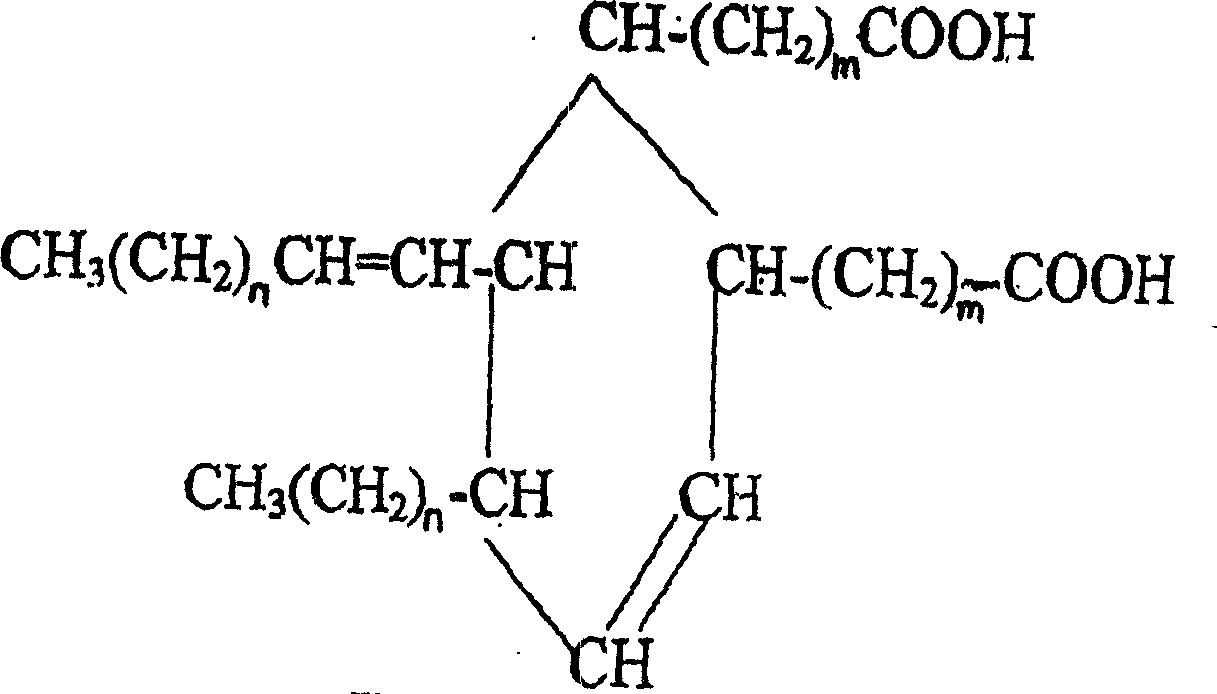

Aliphatic diisocyanate and preparation method and purposes thereof

ActiveCN101805270BHigh yieldEasy to operatePreparation from carboxylic acid nitrogen analoguesFibre treatmentElastomerPolymer science

The invention provides a type of aliphatic diisocyanate with a novel chemical structure, which is C21-36 aliphatic diisocyanate, has the same excellent performance with other traditional aliphatic isocyanates, and is used for preparing polyurethane varnish, coating, elastomer, adhesive, textile finishing agent, rocket propellant and the like. The invention also provides a preparation method of this type of substance, which comprises the following steps that: (a) unsaturated dicarboxylic acid with a special structure or the ester solution thereof are catalyzed and hydrogenised to prepare saturated diacid; (b) the saturated diacid is dissolved into inert solvent and added with chloride agent to react and prepare binary acid chloride; (c) sodium azide is added in to react and prepare the corresponding azide; and (d) the azide is isomerized and decomposed to prepare an aliphatic diisocyanate crude product. The method is characterized by lower condition requirements, safety, environmental-friendliness, fewer side effects, high yield and easy wide popularization in industry.

Owner:浙江优创材料科技股份有限公司

Textile finishing agent

InactiveCN106012499AImproves UV protectionGood flame retardantLight resistant fibresHeat resistant fibresPolybutyleneAdipate

The invention discloses a textile finishing agent. The textile finishing agent comprises components in parts by mass as follows: 2-8 parts of hexamethylene diisocyanate, 10-15 parts of polybutylene glyool adipate, 3-5 parts of silver nitrate, 20-30 parts of poly (butyl acrylate), 10-20 parts of a hydrophilic chain extender N-methyldiethanolamine, 2-5 parts of caprolactam and 9-15 parts of talcum powder. The textile finishing agent has multiple better functions of ultraviolet protection, flame retardance, antibacterium and the like.

Owner:JIANGSU HUAYI GARMENT CO LTD

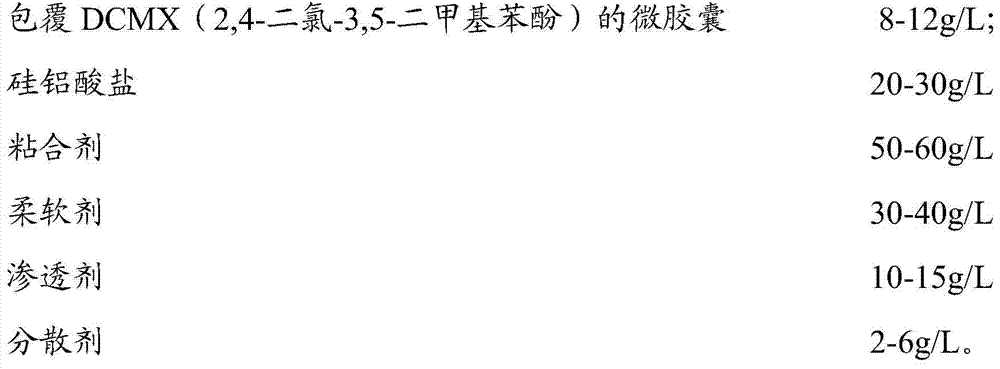

A long-acting antibacterial and deodorizing finishing agent for woolen sweaters

ActiveCN105220494BIdeal antibacterial and deodorizing effectImprove antibacterial propertiesAnimal fibresAdhesiveMating

The invention belongs to the field of textile finishing agents, in particular to a long-acting antibacterial, deodorizing and deodorizing finishing agent for woolen sweaters. It includes components at the following concentrations: 8-12g / L DCMX-coated microcapsules, 20-30g / L aluminosilicate, 50-60g / L binder, 30-40g / L softener , 10‑15g / L penetrating agent, 2‑6g / L dispersant. The technical scheme provided by the present invention makes the woolen sweater after its finishing have very ideal antibacterial, deodorizing and deodorizing effects through the synergistic effect of the microcapsules coated with DCMX and aluminosilicate. Adhesive, so that the above effects still maintain a high antibacterial and deodorizing effect after repeated washing.

Owner:苏州思扬知识产权咨询有限公司

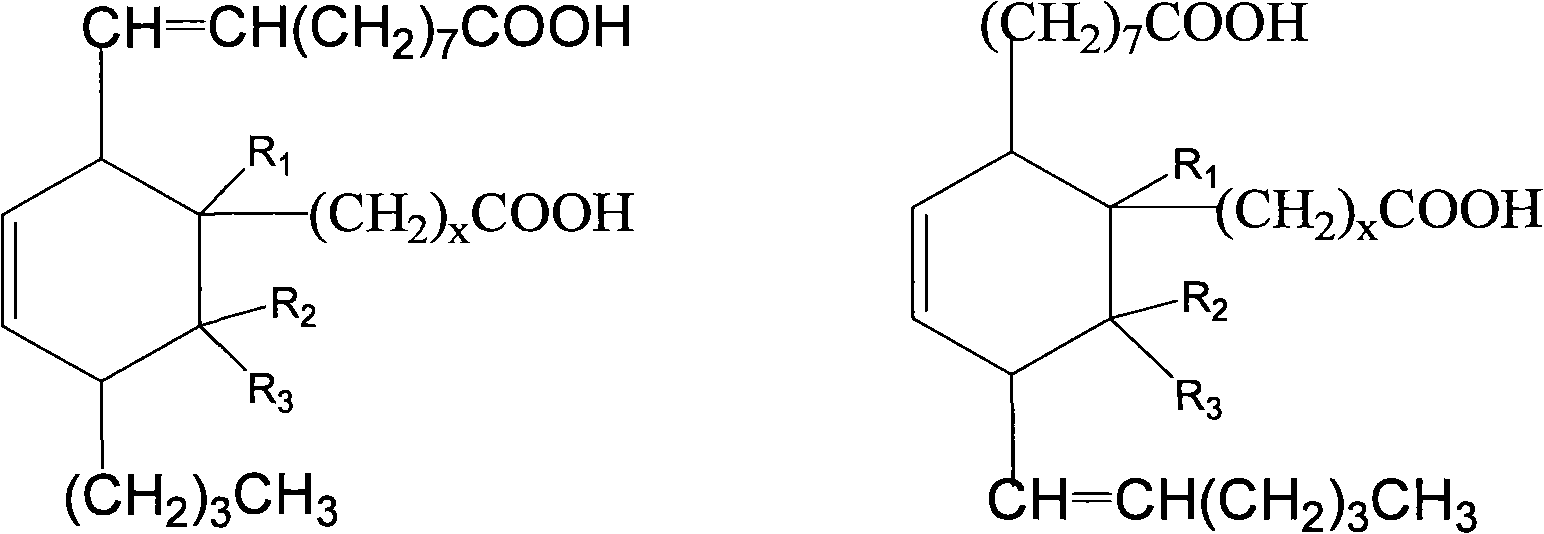

Preparation method and application of C23-38 cycloaliphatic diisocyanate

ActiveCN103102288ASingle configurationLess side effectsIsocyanic acid derivatives preparationOrganic compound preparationElastomerLacquer

The invention provides a preparation method and application of C23-38 cycloaliphatic diisocyanate. The method comprises the following steps: preparing unsaturated cycloaliphatic diacid or ester by using dehydrated ricinoleic acid or ester and a double-bond-containing fatty acid or ester as raw materials; preparing corresponding cyanogens through ammoniation dehydration; preparing corresponding saturated diamine by catalytic hydrogenation; and finally reacting with phosgene to prepare the corresponding cycloaliphatic diisocyanate. The acid or ester extracted from ricinus oil is used as a basic raw material, the production raw material is available, the cost is low, the configuration of the prepared cycloaliphatic diisocyanate is single, the side reaction is less, the molecular weight is between 300-500, the production difficulty is small, the preparation method is simple to operate, mild in condition, environment-friendly, safe in production, and in favor of industrial popularization application, and can be used for preparing polyurethane lacquer, coating, elastomer, adhesive, textile finishing agent and important component of rocket propellant.

Owner:陕西聚泰新材料科技有限公司

A kind of method utilizing ursolic acid extract to prepare antibacterial type textile finishing agent

ActiveCN110499644BIncrease contentHigh antibacterial activityBiocideBiochemical fibre treatmentUrsolic acidCellulose fiber

The invention relates to the field of textile cultural relics protection, and discloses a method for preparing an antibacterial textile finishing agent by using ursolic acid extract. The invention combines the two-phase extraction method and the microwave extraction method to shorten the extraction time and improve the extraction efficiency. The present invention adopts (NH 4 ) 2 SO 4 The mixed solution of solution and ethanol is used as the extraction agent, which is beneficial to reduce the viscosity and improve the diffusion ability and solubility of the liquid, so that the extracted ursolic acid content increases. In the present invention, ursolic acid and nano-zinc oxide are used as antibacterial agents to improve the antibacterial activity of textiles, and simultaneously, 3 (trimethoxysilyl) propyl dimethyl octadecyl ammonium chloride is added in the preparation process of textile finishing agents and 3-imino-N-nitrided acetamidobutyrolactam, so that the finishing agent can not only chemically combine with the cellulose fiber, but also polycondensate into a film, so that the antibacterial component of the finishing agent has washing resistance.

Owner:ZHEJIANG SCI-TECH UNIV

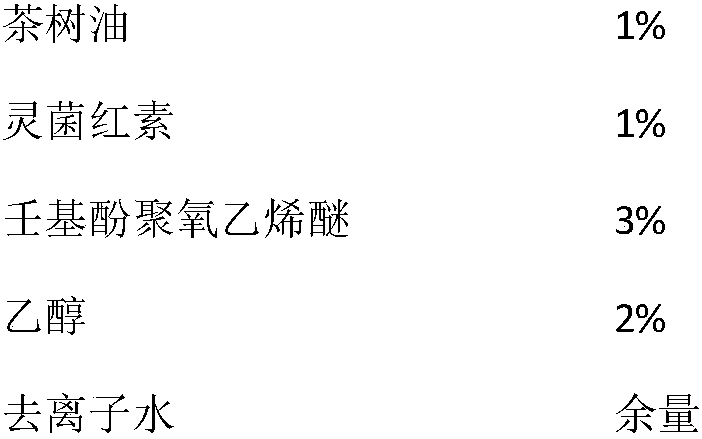

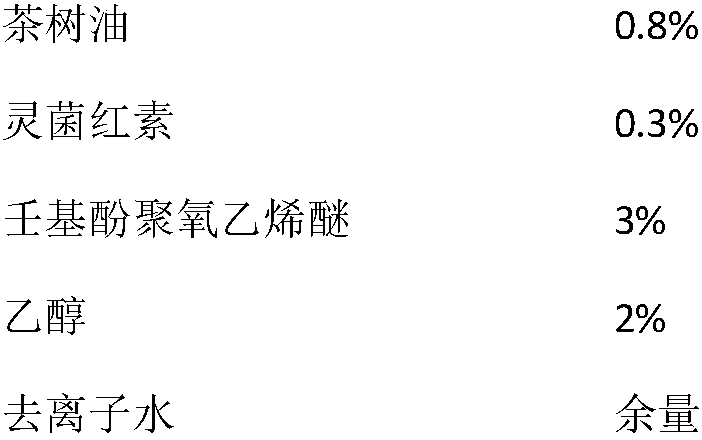

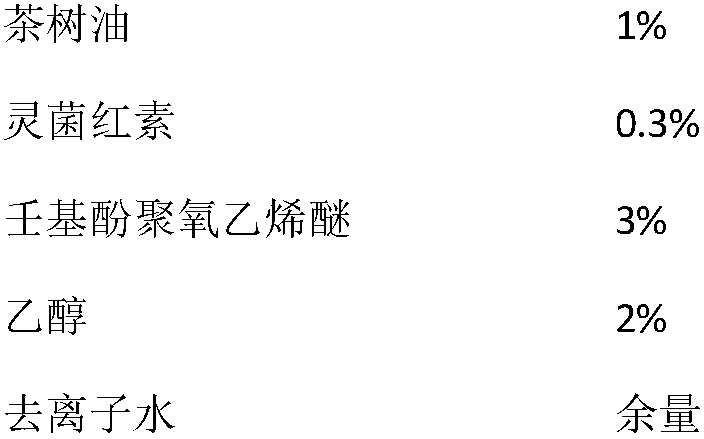

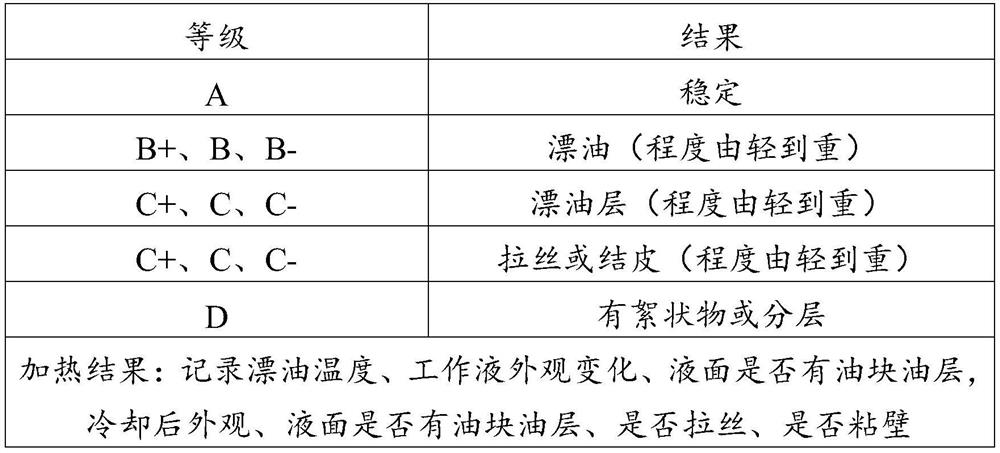

Textile finishing agent containing tea tree oil and application thereof

InactiveCN108411622AAntibacterialTaking into account lifeBiochemical fibre treatmentAdditive ingredientAntibacterial activity

The invention belongs to the field of textile finishing agents, and particularly relates to a textile antibacterial agent containing tea tree oil and prodigiosin and application thereof; antibacterialactive ingredients in the textile finishing agent comprises tea tree oil and prodigiosin, wherein the weight percentage of the tea tree oil in the textile finishing agent is 0.1 to 1% (m / v), and theweight percentage of the prodigiosin in the textile finishing agent is 0.1 to 3% (m / v). In addition, when the weight ratio of the tea tree oil to the prodigiosin in the textile finishing agent is 0.8%: 0.3%, both the antibacterial property and the antibacterial life can be achieved, and the textile finishing agent can be used as a preferred textile finishing agent.

Owner:佛山市尚柏科技有限公司

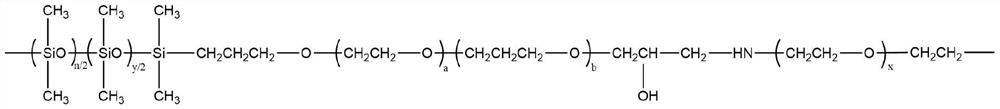

Organic silicon softening agent, preparation method thereof and application of organic silicon softening agent in dark fabric

PendingCN114855461AEnhancement effect is goodImprove stabilityGrip property fibresVegetal fibresOrganic acidPolypropylene glycol

The invention provides an organic silicon softening agent, a preparation method thereof and application of the organic silicon softening agent in dark fabric, and belongs to the technical field of textile finishing agents. The organic silicon softening agent provided by the invention is prepared from the following components in parts by weight: 100 parts of compound deepening crude oil, 10 to 50 parts of compound emulsifier, 0 to 100 parts of polyethylene glycol-polypropylene glycol compound, 1 to 2 parts of organic acid and 100 to 300 parts of deionized water. The organosilicon softener provided by the invention can reduce the refractive index of the surface of a fabric through after-treatment, achieves a darkening effect, enables the fabric to be soft in hand feeling, enables the hand feeling finishing and color darkening of the fabric to be carried out at the same time, is energy-saving and environment-friendly, saves dye, and reduces the cost.

Owner:广东创新精细化工实业有限公司

A washing-resistant flame retardant synergist for textiles and its preparation method and application

ActiveCN107759763BEasy to useRaw materials are cheap and easy to getHeat resistant fibresLiquid repellent fibresPolymer sciencePolythylene glycol

The invention discloses a laundering-resisting and flame-retarding synergist for textiles as well as a preparation method and application thereof. The flame-retarding synergist is prepared from the following substances in parts by mass: 40 to 60 parts of a polyurethane flame retardant, 3 to 10 parts of an emulsifier, 5 to 15 parts of an organic acid ester type flame retardant, 4 to 8 parts of ammonium dihydrogen phosphate and 80 parts of de-ionized water, wherein a structural general formula of the polyurethane flame retardant is shown as formula I, and a, b and c are arbitrary integers from 1to 4; R1 is a residue of diisocyanate; R2 is a residue of halogen-containing alcohol; R3 is a residue of polyol; R4 is a residue of methoxypolyethylene glycols; and R5 is a residue of an end cappingagent. The laundering-resisting and flame-retarding synergist for the textiles, provided by the invention, is mainly applied to functional finishing of the textiles and can be used for synergizing thelaundering resistance and the flame-retarding performance of a textile finishing agent; and the laundering-resisting and flame-retarding synergist has the advantages of cheap and easy-to-obtain raw materials, simple preparation technology and safety and environment protection. The formula I is shown in the description.

Owner:BEIJING CTA TEX CHEM

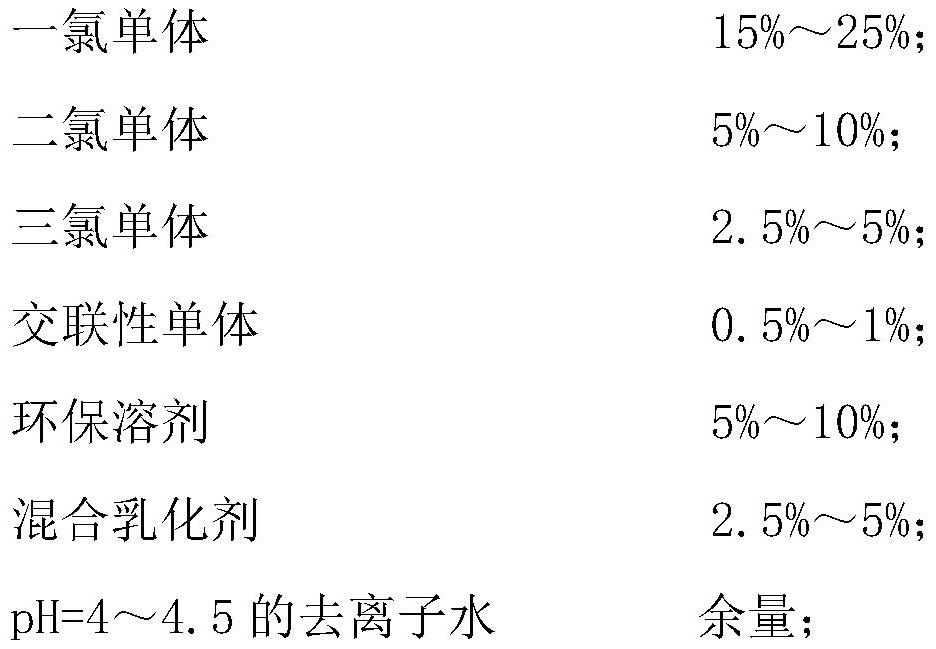

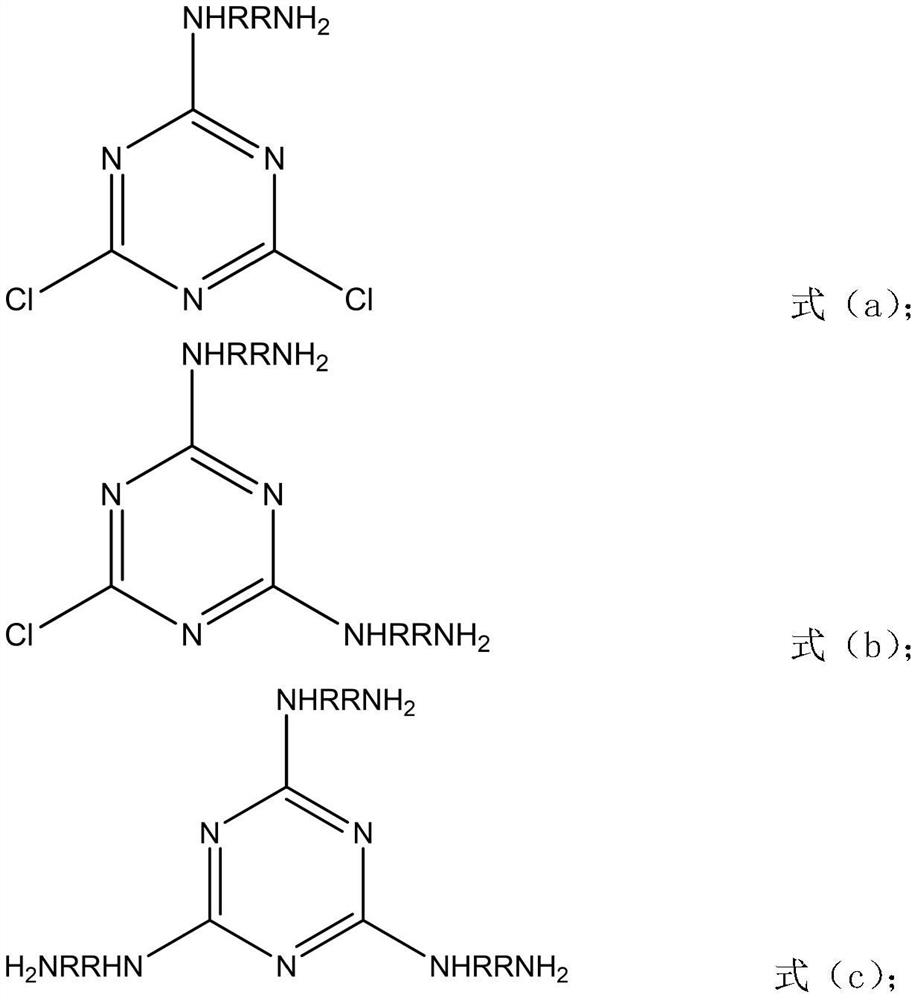

Hydrophilic organosilicon finishing agent for cotton fabric and preparation method thereof

ActiveCN111607969AImprove washabilityPlay a high hydrophilic roleLiquid repellent fibresGrip property fibresPolymer scienceTextile finisher

The invention discloses a hydrophilic organosilicon finishing agent for cotton fabric and a preparation method thereof and relates to the technical field of textile auxiliaries. The organosilicon finishing agent is prepared from the following components of, by weight, 15%-25% of monochloro monomer, 5%-10% of dichloro monomer, 2.5%-5% of trichloro monomer, 0.5%-1% of cross-linking monomer, 5%-10% of environmentally friendly solvents, 2.5%-5% of mixed emulsifier, and the balance deionized water with the pH is equal to 4-4.5. The hydrophilic organosilicon finishing agent for the cotton fabric andthe preparation method thereof have the advantage that the textile finishing agent better in hydrophilic performance is provided.

Owner:绍兴海成化工有限公司

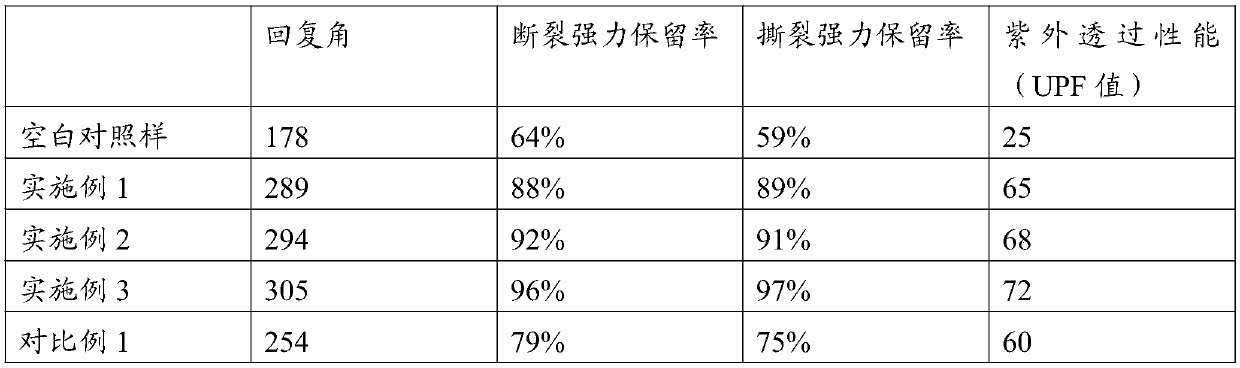

Preparation method of crease-resistant and anti-ultraviolet finishing agent

InactiveCN107938329AOvercoming Diffusion DifficultiesImprove wrinkle resistanceVegetal fibresPolyethylene glycolTrimethylolpropane

The invention relates to a preparation method of a crease-resistant and anti-ultraviolet finishing agent, and belongs to the technical field of a textile finishing agent. In particular, the preparation method comprises the following steps: mixing acetylacetone, diisopropyl naphthalene sulfonic acid sodium salt, ethanol and water, and heating after mixing uniformly; adding silver surface mofified zinc oxide, polyethylene glycol terephthalate, dioctyl sebacate and methyl silicate into the mixed solution prepared by the step 2, and heating while stirring; adding trimethylolpropane, maleic anhydride, dihydroxy methyl acrylic acid, an anion finishing agent, a perfume finishing agent and a fixing agent into a high-speed stirring machine, mixing uniformly and performing ultrasonic treatment to remove bubbles; and adding the mixture with bubbles removed into the mixed solution which is stirred uniformly in the step 3, reacting and finally completing preparation. According to the product, the crease-resistant effect and the anti-ultraviolet capacity of the cotton fabric are improved, good breakage and tearing strength are retained, and the defect that finishing is conducted repeatedly for many times in the traditional process is overcome.

Owner:INTIME FASHION SUZHOU CO LTD

Isocyanate alkyl substituted cyclohexane and preparation method as well as application thereof

ActiveCN101792402BEasy to industrializeEasy to operateIsocyanic acid derivatives preparationOrganic compound preparationElastomerPolymer science

The invention relates to a compound shown in formula Ia or Ib, wherein one of p and q is equal to 0, and the other one of p and q is equal to 1; m and y are respectively equal to integers from 0 to 12 independently, and the sum of m and y is equal to 12; and n and x are respectively equal to integers from 0 to 12 independently, and the sum of n and x is equal to 12. The invention also relates to a preparation method of the compound shown in formula Ia or Ib and application of the compound shown in formula Ia or Ib as a component for producing polyurethane lacquer, paint, elastomers, adhesives, textile finishing agents or rocket propellants.

Owner:浙江优创材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com