Textile finishing agent and applications of textile finishing agent in preparation of wicking fabrics

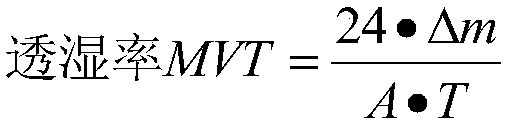

A finishing agent, a technology of moisture absorption and perspiration, which is applied in the textile field, can solve the problems of unsatisfactory moisture absorption and perspiration, weak perspiration, poor durability, etc., and achieves the effect of improving quick-drying perspiration and moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing moisture-permeable and sweat-wicking dry pajamas, comprising the following steps, and the parts are all parts by weight:

[0040] (1) Preparation of textile finishing agent: Mix 0.8 parts of penetrant with 50 parts of water, stir at 40°C at 200 rpm for 15 minutes to obtain an aqueous solution of penetrant, then add 70 parts of water, 15 parts of chitosan oligosaccharide solution, and 2 parts of perspiration finishing agent were stirred for 30 minutes at 200 rpm to obtain textile finishing agent;

[0041] (2) Impregnation: Immerse the fabric in the textile finishing agent for 25 minutes, the impregnation temperature is 25°C, the bath ratio is 1:6, and then one dipping and one rolling are adopted, and the excess rate is 70%, so as to obtain the fabric treated with the impregnating solution;

[0042] (3) Post-treatment of the fabric: Dry the fabric treated with the impregnation solution at 75°C for 5 minutes, place the working gas in nitrogen, the wo...

Embodiment 2

[0047] A method for preparing moisture-permeable and sweat-wicking dry pajamas, comprising the following steps, and the parts are all parts by weight:

[0048] (1) Preparation of textile finishing agent: Mix 0.8 parts of penetrant with 50 parts of water, stir at 40°C at 200 rpm for 15 minutes to obtain an aqueous solution of penetrant, then add 70 parts of water and 15 parts of modified chitosan oligosaccharide solution 1. 2 parts of moisture-absorbing and sweat-wicking finishing agent, stirred for 30 minutes at 200 rpm to obtain textile finishing agent;

[0049] (2) Impregnation: Immerse the fabric in the textile finishing agent for 25 minutes, the impregnation temperature is 25°C, the bath ratio is 1:6, and then one dipping and one rolling are adopted, and the excess rate is 70%, so as to obtain the fabric treated with the impregnating solution;

[0050] (3) Post-treatment of the fabric: Dry the fabric treated with the impregnation solution at 75°C for 5 minutes, place the w...

Embodiment 3

[0058] A method for preparing moisture-permeable and sweat-wicking dry pajamas, comprising the following steps, and the parts are all parts by weight:

[0059] (1) Preparation of textile finishing agent: Mix 0.8 parts of penetrant with 50 parts of water, stir at 40°C at 200 rpm for 15 minutes to obtain an aqueous solution of penetrant, then add 70 parts of water and 15 parts of modified chitosan oligosaccharide solution 1. 2 parts of moisture-absorbing and sweat-wicking finishing agent, stirred for 30 minutes at 200 rpm to obtain textile finishing agent;

[0060] (2) Impregnation: Immerse the fabric in the textile finishing agent for 25 minutes, the impregnation temperature is 25°C, the bath ratio is 1:6, and then one dipping and one rolling are adopted, and the excess rate is 70%, so as to obtain the fabric treated with the impregnating solution;

[0061] (3) Fabric post-treatment: Dry the fabric treated with the impregnating solution at 75°C for 5 minutes, place it in a low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com