Graphene-modified maleic-anhydride polyethylene wax emulsion and preparing method thereof

A polyethylene wax emulsion, maleic anhydride technology, applied in biochemical fiber processing, textile and papermaking, fiber processing, etc., can solve the problems of poor dispersion, unstable performance, etc., to improve cutting resistance, avoid pollution, raw materials Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

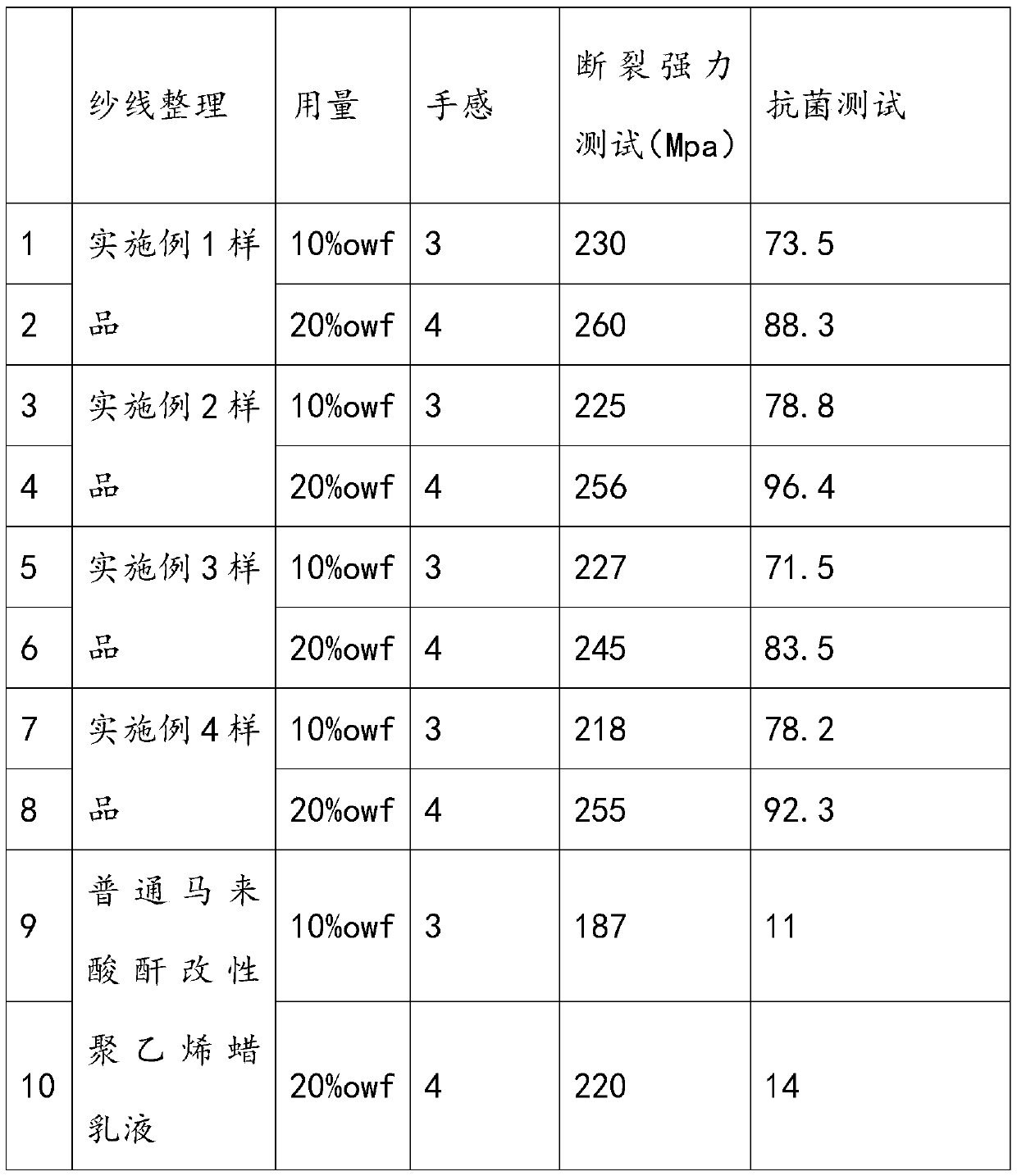

Examples

Embodiment 1

[0033] The graphene-modified maleic anhydrided polyethylene wax emulsion provided in this embodiment includes: 5 g of monolayer graphene, 15 g of isomeric tridecyl alcohol polyoxyethylene ether (EO number is 6), maleic anhydride modified polyethylene Wax 20g, stearyl alcohol 5g, water 54.7g and potassium hydroxide 0.2g.

[0034] The preparation method of the graphene-modified maleic anhydrided polyethylene wax emulsion provided by the present embodiment comprises the following steps:

[0035] Step (1), preparing an emulsification kettle with a fractionation device, is provided with a thermometer, a stirrer and a nitrogen inlet pipe in the emulsification kettle;

[0036] Step (2), drop in successively single-layer graphene 5g, polyoxyethylene tridecyl alcohol ether (EO number is 6) 15g, maleic anhydride modified polyethylene wax 20g, 5g stearyl alcohol, 54.7g water and hydrogen Potassium oxide 0.2g;

[0037] Step (3), input nitrogen gas from the nitrogen gas inlet pipe, under...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] The graphene-modified maleic anhydrided polyethylene wax emulsion provided in this embodiment includes: graphene oxide 3g, isomeric tridecyl alcohol polyoxyethylene ether (EO number is 6) 15g, maleic anhydride modified polyethylene wax 20g, 4g stearyl alcohol, 57.8g water and 0.2g neutralizer.

[0045] The preparation method of the graphene-modified maleic anhydrided polyethylene wax emulsion provided by the present embodiment comprises the following steps:

[0046] Step (1), preparing an emulsification kettle with a fractionation device, is provided with a thermometer, a stirrer and a nitrogen inlet pipe in the emulsification kettle;

[0047] Step (2), successively put in 3g of graphene oxide, 15g of isomeric tridecyl alcohol polyoxyethylene ether (EO number is 6), 20g of maleic anhydride modified polyethylene wax, 4g of stearyl alcohol, 57.8g of water and neutralization Dosage 0.2g;

[0048] Step ...

Embodiment 3

[0054] The differences between this embodiment and embodiment 1 and embodiment 2 are:

[0055] The graphene-modified maleic anhydrided polyethylene wax emulsion provided in this embodiment includes: graphene oxide 4g, isomeric tridecyl alcohol polyoxyethylene ether (EO number is 6) 16g, maleic anhydride modified polyethylene wax 20g, 2g stearyl alcohol, 57.8g water and 0.2g sodium hydroxide.

[0056] The preparation method of the graphene-modified maleic anhydrided polyethylene wax emulsion provided by the present embodiment comprises the following steps:

[0057] Step (1), preparing an emulsification kettle with a fractionation device, is provided with a thermometer, a stirrer and a nitrogen inlet pipe in the emulsification kettle;

[0058] Step (2), successively drop into graphene oxide 4g, isomeric tridecyl alcohol polyoxyethylene ether (EO number is 6) 16g, maleic anhydride modified polyethylene wax 20g, 2g stearyl alcohol, 57.8g water and hydrogenation Sodium 0.2g;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com