Functional fabric and preparation process thereof

A preparation process and functional technology, applied in the field of textile fabrics, can solve the problems of affecting the effect of other functional finishing agents, antibacterial finishing agent, poor compatibility, unstable working fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

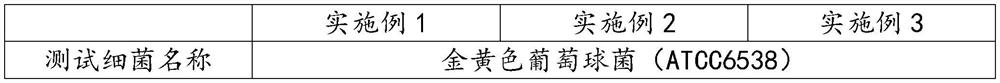

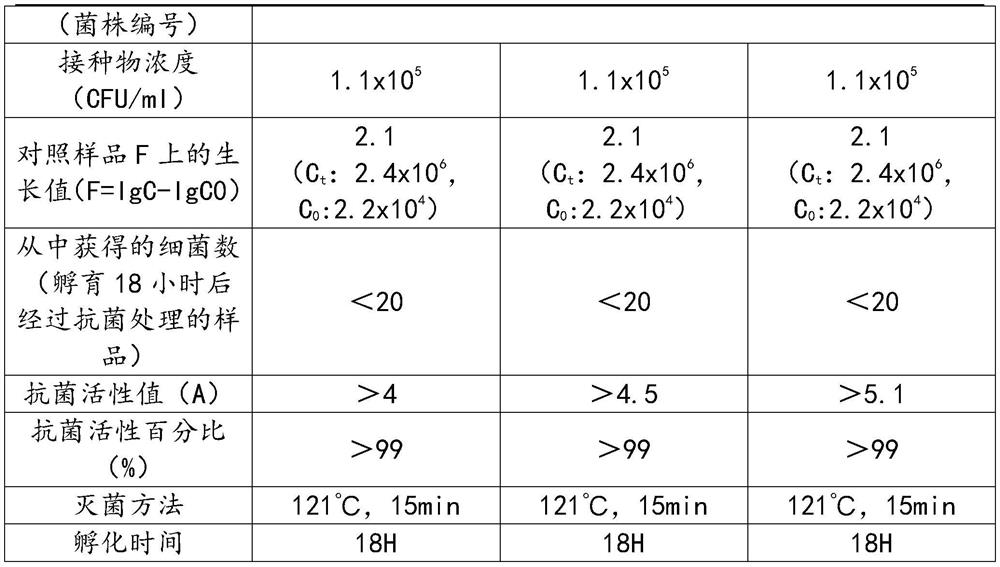

Embodiment 1

[0044] A functional fabric, including cotton yarn and linen yarn as the warp yarn, and polyester yarn as the weft yarn through the warp and weft knitting machine to weave in a one-up and one-down manner, wherein the polyester yarn is twisted by several strands of special-shaped fibers, The special-shaped fiber is extruded and spun through the holes of the special-shaped spinneret. In this embodiment, the cross-section of the special-shaped yarn is Y-shaped.

[0045] The gray cloth is put into the collagen finishing agent and the antibacterial finishing agent successively and soaked to obtain the fabric, wherein the collagen finishing agent contains by weight percentage:

[0046] Hydrolyzed gel 5%;

[0047] Silk protein 20%;

[0048] Glycine 20%;

[0049] Hydroxyproline 10%;

[0050] Silk fibroin 1%;

[0051] The remainder is water;

[0052] Antibacterial finishing agent comprises by weight percentage content:

[0053] Active nano zinc oxide 1%;

[0054] Dimethyl diallyl a...

Embodiment 2

[0063] A functional fabric, including cotton yarn and linen yarn as the warp yarn, and polyester yarn as the weft yarn through the warp and weft knitting machine to weave in a one-up and one-down manner, wherein the polyester yarn is twisted by several strands of special-shaped fibers, The special-shaped fiber is extruded and spun through the holes of the special-shaped spinneret. In this embodiment, the cross-section of the special-shaped yarn is Y-shaped.

[0064] The gray cloth is put into the collagen finishing agent and the antibacterial finishing agent successively and soaked to obtain the fabric, wherein the collagen finishing agent contains by weight percentage:

[0065] Hydrolyzed gel 10%;

[0066] Silk protein 15%;

[0067] Glycine 25%;

[0068] Hydroxyproline 5%;

[0069] Silk fibroin 3%;

[0070] The remainder is water;

[0071] Antibacterial finishing agent comprises by weight percentage content:

[0072] Active nano zinc oxide 1.2%;

[0073] Dimethyldially...

Embodiment 3

[0082] A functional fabric, including cotton yarn and linen yarn as the warp yarn, and polyester yarn as the weft yarn through the warp and weft knitting machine to weave in a one-up and one-down manner, wherein the polyester yarn is twisted by several strands of special-shaped fibers, The special-shaped fiber is extruded and spun through the holes of the special-shaped spinneret. In this embodiment, the cross-section of the special-shaped yarn is Y-shaped.

[0083] The gray cloth is put into the collagen finishing agent and the antibacterial finishing agent successively and soaked to obtain the fabric, wherein the collagen finishing agent contains by weight percentage:

[0084] Hydrolyzed gel 15%;

[0085] Silk protein 10%;

[0086] Glycine 35%;

[0087] Hydroxyproline 5%;

[0088] Silk fibroin 5%;

[0089] The remainder is water;

[0090] Antibacterial finishing agent comprises by weight percentage content:

[0091] Active nano zinc oxide 1%;

[0092] Dimethyl diallyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com