Preparation method of environment-friendly ironing-free antibacterial finishing agent for wool fabrics

An antibacterial finishing agent, an environment-friendly technology, applied in the field of preparation of wool fabric environment-friendly non-ironing antibacterial finishing agent, can solve the problems such as ineffective effects, and achieve the effects of strong promotion value, excellent non-ironing antibacterial performance, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

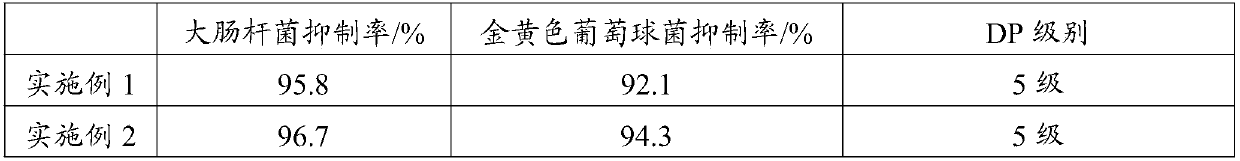

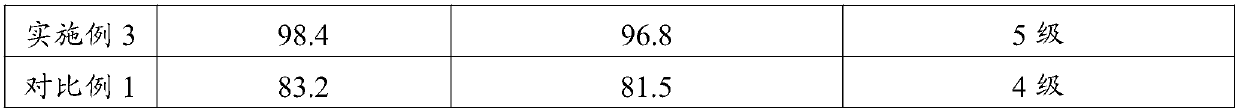

Examples

Embodiment 1

[0018] A preparation method of an environment-friendly non-ironing antibacterial finishing agent for wool fabrics, the preparation method comprising the following steps:

[0019] Step 1. Weigh 10 parts by mass of chitin and dissolve it in 30 parts by mass of 15wt.% dilute hydrochloric acid, and react at a temperature of 40° C. for 3 hours;

[0020] Step 2. Add 0.5 parts by mass of octylphenol polyoxyethylene ether, 3 parts by mass of polyethylene glycol and 2 parts by mass of phthalic anhydride to the reacted mixture, and heat up to 150° C. for 2 hours;

[0021] Step 3. Take 5 parts by mass of Echinacea seeds and pulverize them to 20 meshes, then put them into 40 parts by mass of 60wt.% ethanol aqueous solution for stirring and extraction, centrifuge after extraction, and collect the supernatant;

[0022] Step 4. Add the supernatant prepared in step 3 to the mixed material after the reaction in step 2, then add 40 parts by mass of non-ironing resin FR-E and 5 parts by mass of ...

Embodiment 2

[0024] A preparation method of an environment-friendly non-ironing antibacterial finishing agent for wool fabrics, the preparation method comprising the following steps:

[0025] Step 1. Weighing 16 parts by mass of chitin was dissolved in 40 parts by mass of 15wt.% dilute hydrochloric acid, and reacted at a temperature of 60° C. for 4 hours;

[0026] Step 2. Add 0.5 to 1.5 parts by mass of octylphenol polyoxyethylene ether, 3 to 7 parts by mass of polyethylene glycol and 4 parts by mass of phthalic anhydride to the reacted mixture, and heat up to 160° C. for 4 hours;

[0027] Step 3. Take 10 parts by mass of Echinacea seeds and pulverize them to 50 meshes, then put them into 50 parts by mass of 60wt.% ethanol aqueous solution for stirring and extraction, centrifuge after extraction, and collect the supernatant;

[0028] Step 4. Add the supernatant prepared in step 3 to the mixed material after the reaction in step 2, then add 50 parts by mass of non-ironing resin FR-E and 9 p...

Embodiment 3

[0030] A preparation method of an environment-friendly non-ironing antibacterial finishing agent for wool fabrics, the preparation method comprising the following steps:

[0031] Step 1. Weigh 13 parts by mass of chitin and dissolve it in 35 parts by mass of 15wt.% dilute hydrochloric acid, and react at a temperature of 55° C. for 4 hours;

[0032] Step 2. Add 1 mass part of octylphenol polyoxyethylene ether, 5 mass parts of polyethylene glycol and 3 mass parts of phthalic anhydride to the reacted mixture, and heat up to 155 ° C for 3 hours;

[0033] Step 3. Take 8 parts by mass of Echinacea seeds and pulverize them to 40 mesh, then put them into 45 parts by mass of 60wt.% ethanol aqueous solution for stirring and extraction, centrifuge after extraction, and collect the supernatant;

[0034] Step 4. Add the supernatant prepared in step 3 to the mixed material after the reaction in step 2, then add 45 parts by mass of non-ironing resin FR-E and 7 parts by mass of tartaric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com