Production method of water soluble sericin

A technology of sericin and a manufacturing method, applied in the field of water-soluble sericin, can solve the problems of low recovery efficiency, high recovery cost, complicated preparation process, etc., and achieve the effects of improving efficiency, reducing production cost and high-efficiency recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

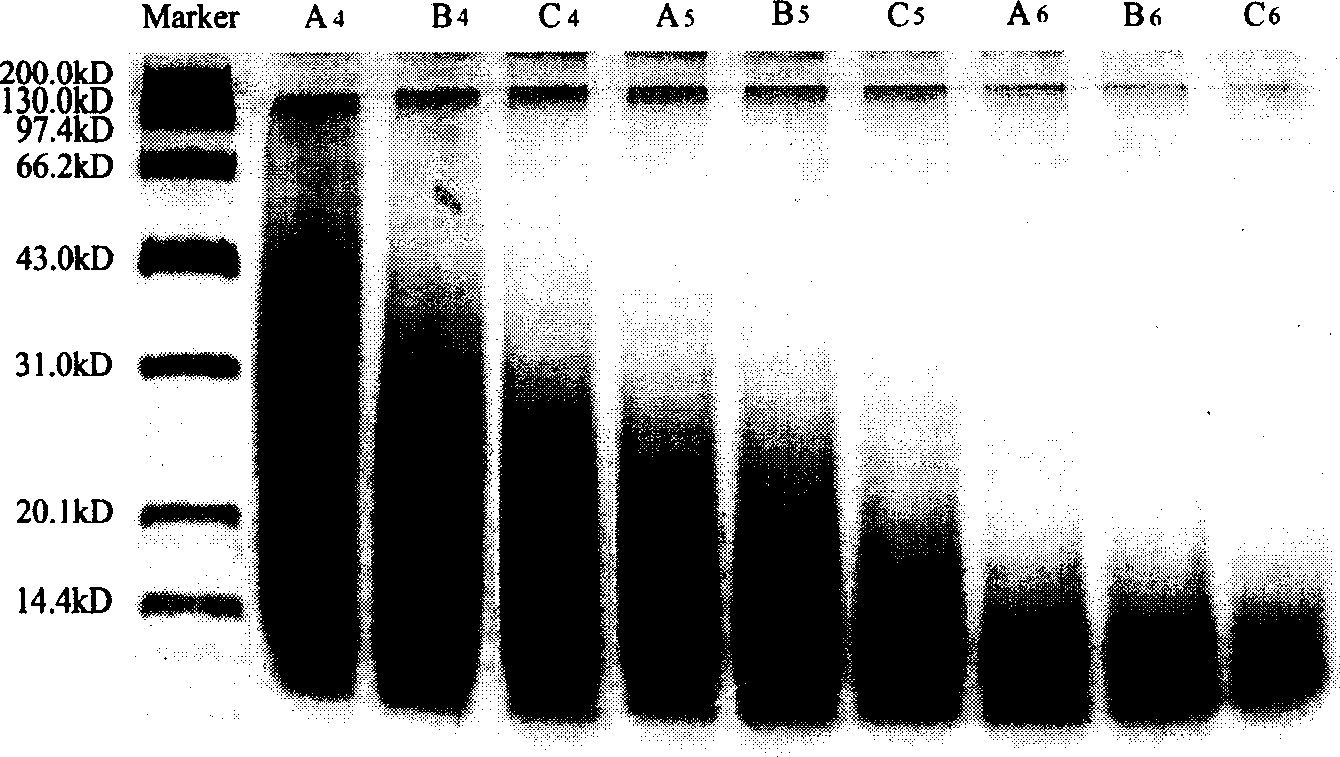

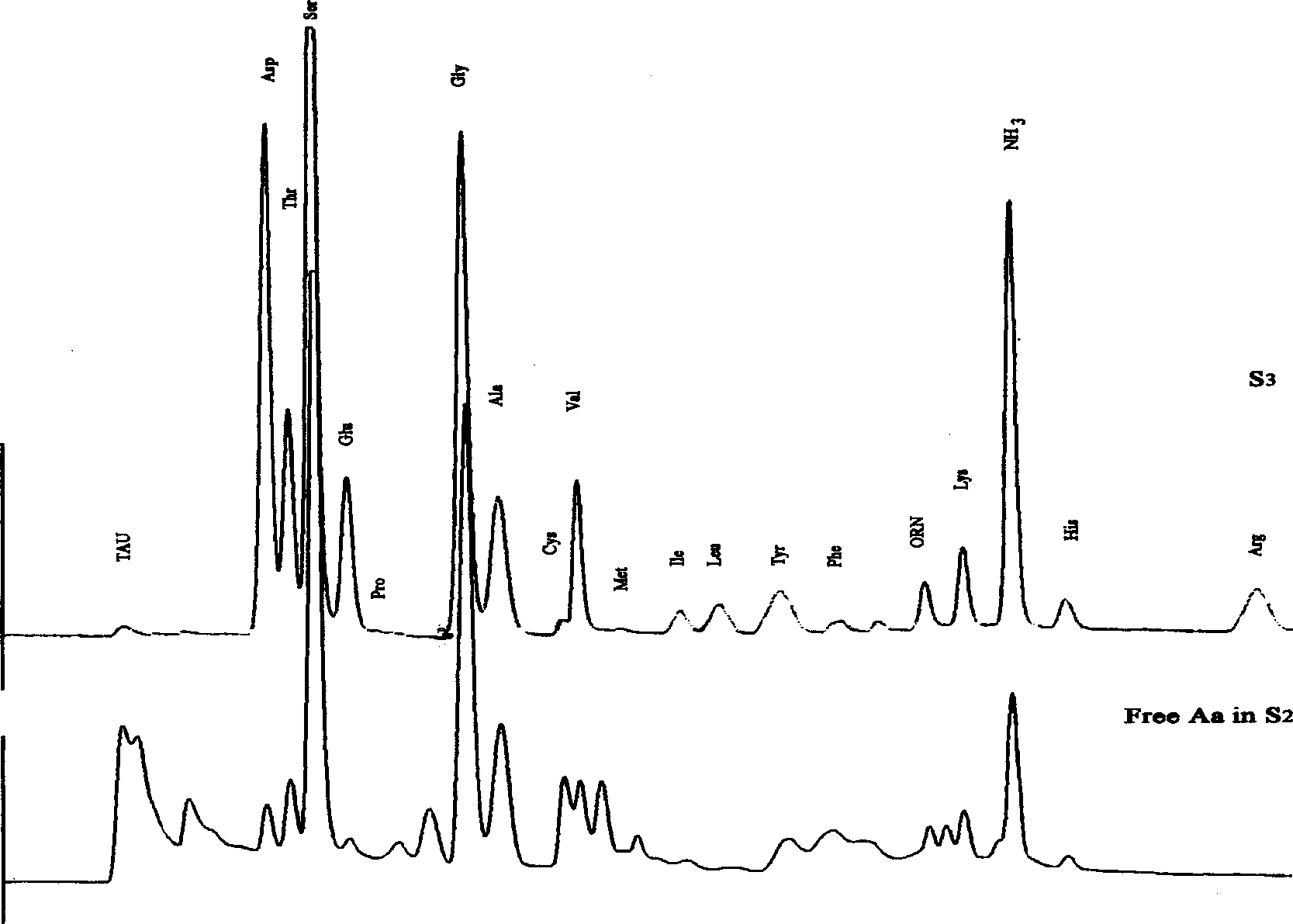

[0021] Weigh raw materials such as cocoon shells, cocoon clothes, waste silk, etc., first rinse in warm water or in weakly alkaline aqueous solution to remove impurities and dust, then add 20 times the amount (V / W) of pure water or use NaOH to adjust the pH to 7~ 8 Immerse in an aqueous solution to make the cocoon or cocoon shell fully swell, then place it in a high-temperature and high-pressure container, and treat it at a temperature of 120°C (0.1MPa pressure) for 1 hour, take out the degummed silk after cooling, and rinse it repeatedly with water. The washing liquid and the degumming liquid are combined to obtain an insoluble sericin solution.

[0022] Adjust the above-mentioned insoluble sericin solution with NaOH, and the pH values are pH=10.0, pH=11.0 and pH=12.0 respectively; or directly spray and dry the above-mentioned degummed sericin solution to make insoluble sericin powder, and make the sericin The powder was first dissolved in hot water, and then adjusted to pH...

Embodiment 2

[0027] Weigh 1Kg of raw materials such as cocoon shells, cocoon clothing, waste silk, etc., first rinse in warm water or in weakly alkaline aqueous solution to remove impurities and dust, and then add 20 times the amount (V / W) of pure water for immersion to make the cocoon clothing Or after the cocoon shell is fully swollen, put it in a high-temperature and high-pressure container, and treat it at a temperature of 120°C (0.1MPa pressure) for 1 hour. After cooling, take out the degummed silk, rinse it repeatedly with water, and combine the washing liquid with the degumming liquid. An insoluble sericin solution was prepared.

[0028] Adjust the obtained insoluble sericin solution to pH 11.0 with NaOH; or directly spray dry the obtained insoluble sericin solution to make insoluble sericin powder, and dissolve the sericin powder with hot water first, Also adjusted to pH 11.0 with NaOH. Next, the insoluble sericin solution after adjusting the pH value above was divided into two gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com