Preparation method of crease-resistant and anti-ultraviolet finishing agent

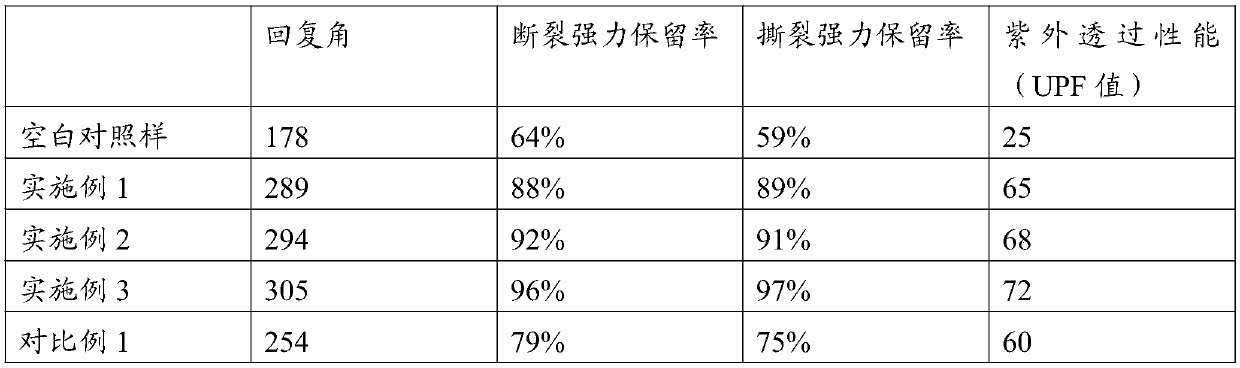

A technology of anti-ultraviolet finishing and finishing agent, applied in fiber treatment, textile and papermaking, plant fiber and other directions, can solve the problems of complex processing technology, increased cost, water and energy consumption, etc., and achieves improved anti-wrinkle effect, good fracture and tear The effect of improving crack strength and UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of an anti-wrinkle and anti-ultraviolet finishing agent, said preparation method comprising the following steps:

[0020] Step 1. Weigh 20 parts by mass of trimethylolpropane, 1 part by mass of silver surface modified zinc oxide, 4 parts by mass of maleic anhydride, 15 parts by mass of polyethylene terephthalate, 2 parts by mass of dimethylol Acrylic acid, 5 parts by mass of negative ion finishing agent, 4 parts by mass of fragrance finishing agent, 0.5 parts by mass of fixing agent, 3 parts by mass of ethanol, 10 parts by mass of dioctyl sebacate, 3 parts by mass of sodium diisopropyl naphthalene sulfonate, 5 parts by mass of Parts by mass of methyl orthosilicate, 20 parts by mass of acetylacetone and 100 parts by mass of water for subsequent use;

[0021] Step 2. Mix acetylacetone, sodium diisopropylnaphthalenesulfonate, ethanol and water, and heat to 60°C after mixing evenly;

[0022] Step 3. Add silver surface modified zinc oxide, polyethylene ...

Embodiment 2

[0026] A preparation method of an anti-wrinkle and anti-ultraviolet finishing agent, said preparation method comprising the following steps:

[0027] Step 1. Weigh 30 parts by mass of trimethylolpropane, 3 parts by mass of silver surface modified zinc oxide, 6 parts by mass of maleic anhydride, 20 parts by mass of polyethylene terephthalate, 4 parts by mass of dimethylol Acrylic acid, 8 parts by mass of negative ion finishing agent, 9 parts by mass of fragrance finishing agent, 2 parts by mass of fixing agent, 5 parts by mass of ethanol, 15 parts by mass of dioctyl sebacate, 7 parts by mass of sodium diisopropyl naphthalene sulfonate, 12 parts by mass Parts by mass of methyl orthosilicate, 30 parts by mass of acetylacetone and 150 parts by mass of water for subsequent use;

[0028] Step 2. Mix acetylacetone, sodium diisopropylnaphthalenesulfonate, ethanol and water, and heat to 70°C after mixing evenly;

[0029] Step 3. Add silver surface modified zinc oxide, polyethylene ter...

Embodiment 3

[0033] A preparation method of an anti-wrinkle and anti-ultraviolet finishing agent, said preparation method comprising the following steps:

[0034] Step 1. Weigh 25 parts by mass of trimethylolpropane, 2 parts by mass of silver surface modified zinc oxide, 5 parts by mass of maleic anhydride, 16 parts by mass of polyethylene terephthalate, 3 parts by mass of dimethylol Acrylic acid, 7 parts by mass of negative ion finishing agent, 8 parts by mass of fragrance finishing agent, 1.5 parts by mass of fixing agent, 4 parts by mass of ethanol, 12 parts by mass of dioctyl sebacate, 6 parts by mass of sodium diisopropyl naphthalene sulfonate, 9 parts by mass Parts by mass of methyl orthosilicate, 25 parts by mass of acetylacetone and 125 parts by mass of water for subsequent use;

[0035] Step 2. Mix acetylacetone, sodium diisopropylnaphthalenesulfonate, ethanol and water, and heat to 68°C after mixing evenly;

[0036] Step 3. Add silver surface modified zinc oxide, polyethylene te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com