Hydrophilic organosilicon finishing agent for cotton fabric and preparation method thereof

A hydrophilic organic and silicon finishing technology, used in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of poor washability, excessive loss of hydrophilicity, and decreased hand feel, and achieve excellent washability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

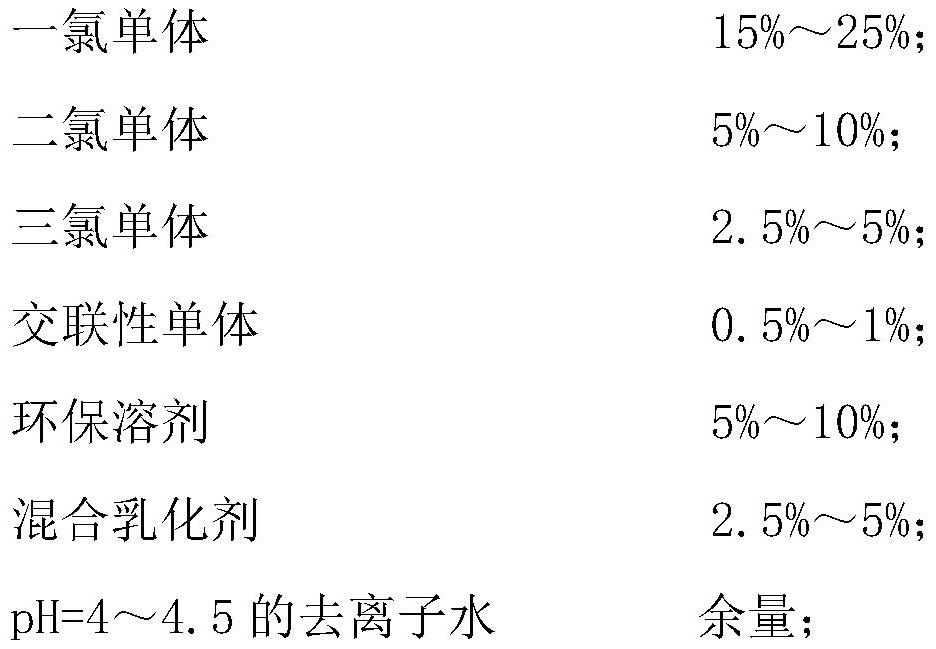

[0051] A hydrophilic organosilicon finishing agent for cotton fabrics disclosed by the invention is prepared from the following components in weight percent:

[0052]

[0053] The cross-linking monomer is vinyl silicone oil with a molecular weight of 1000;

[0054] The environmentally friendly solvent is 1,4-pentanediol;

[0055] The mixed emulsifier is alkoxylated polyethyleneimine and isomeric decanol polyoxyethylene ether, wherein the weight ratio is 1.5:1.

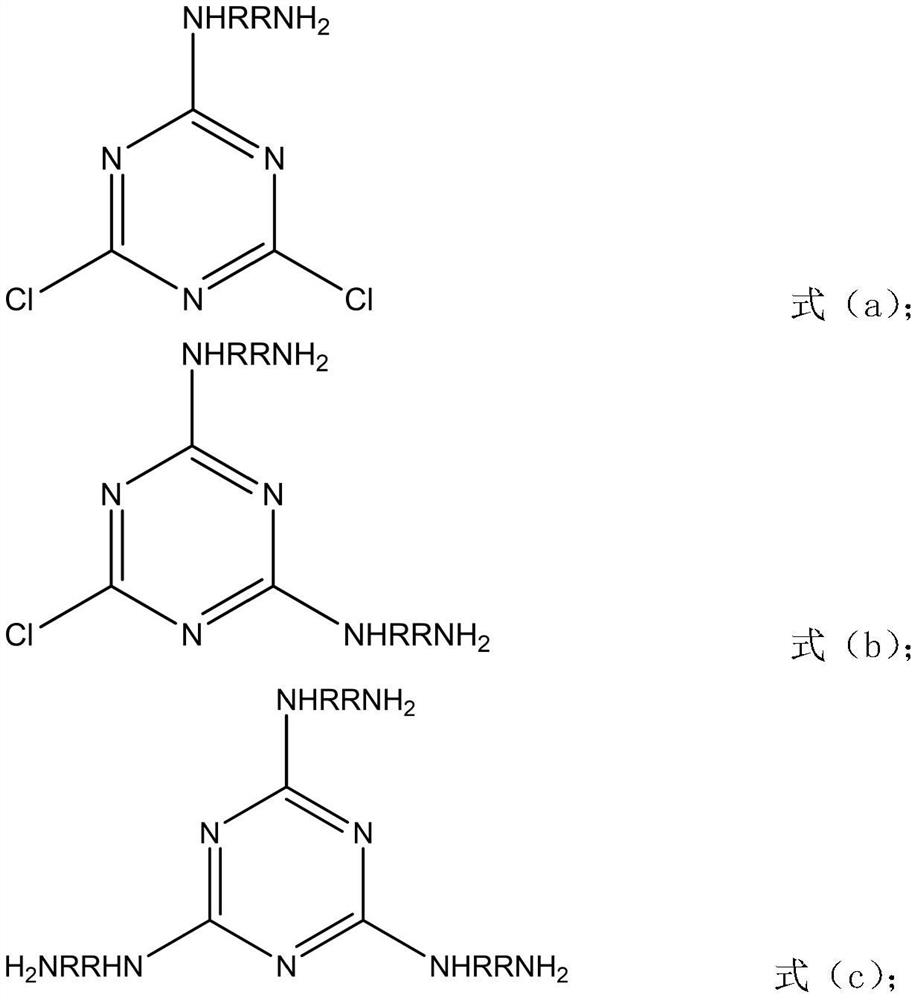

[0056] Wherein, the structural formula of a chlorine monomer is formula (a);

[0057] The structural formula of dichloro monomer is formula (b);

[0058] The structural formula of trichloromonomer is formula (c);

[0059]

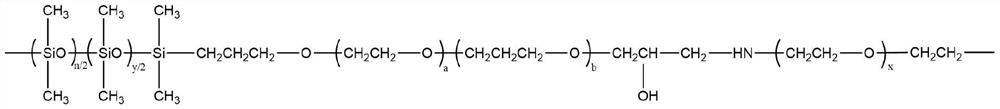

[0060] The viscosity is 50-80 centistokes (25°C)

[0061]

[0062] The viscosity is 100-200 centistokes (25°C)

[0063]

[0064] The viscosity is 200-1000 centistokes (25°C)

[0065] in,

[0066] R is:

[0067]

[0068] 4≤a≤6, 8≤b≤10, 8≤n≤10, 5≤x≤10, 30≤y≤60.

[0069] Monochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com