Method for producing bidirectional elastic flock suede fabric

A production method and technology of suede, applied in the direction of fabric surface trimming, heating/cooling fabric, textile material processing, etc., to achieve the effect of smooth hand, good elasticity and durability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

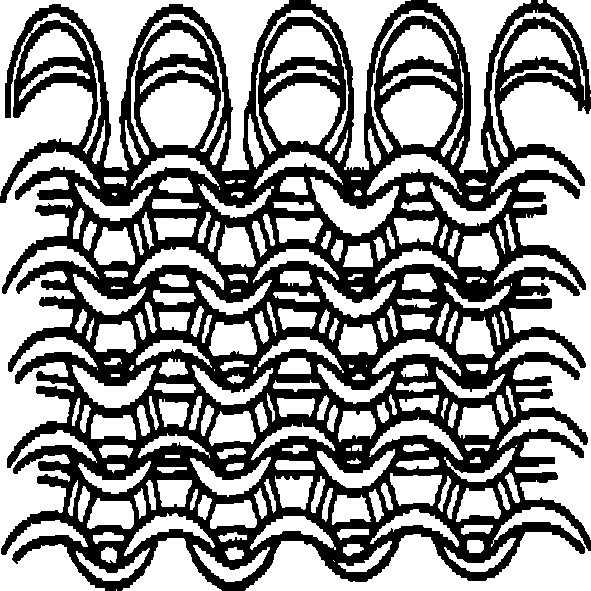

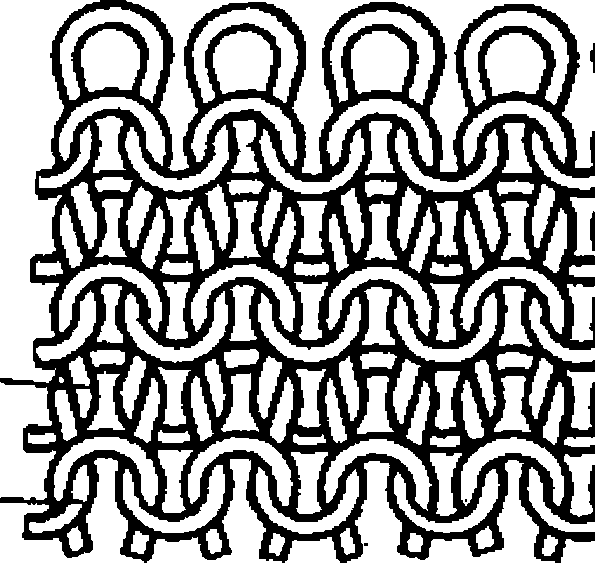

[0031] The production method of the present invention is as Figure 6 As shown, the steps are as follows:

[0032] 1. Selection of raw materials

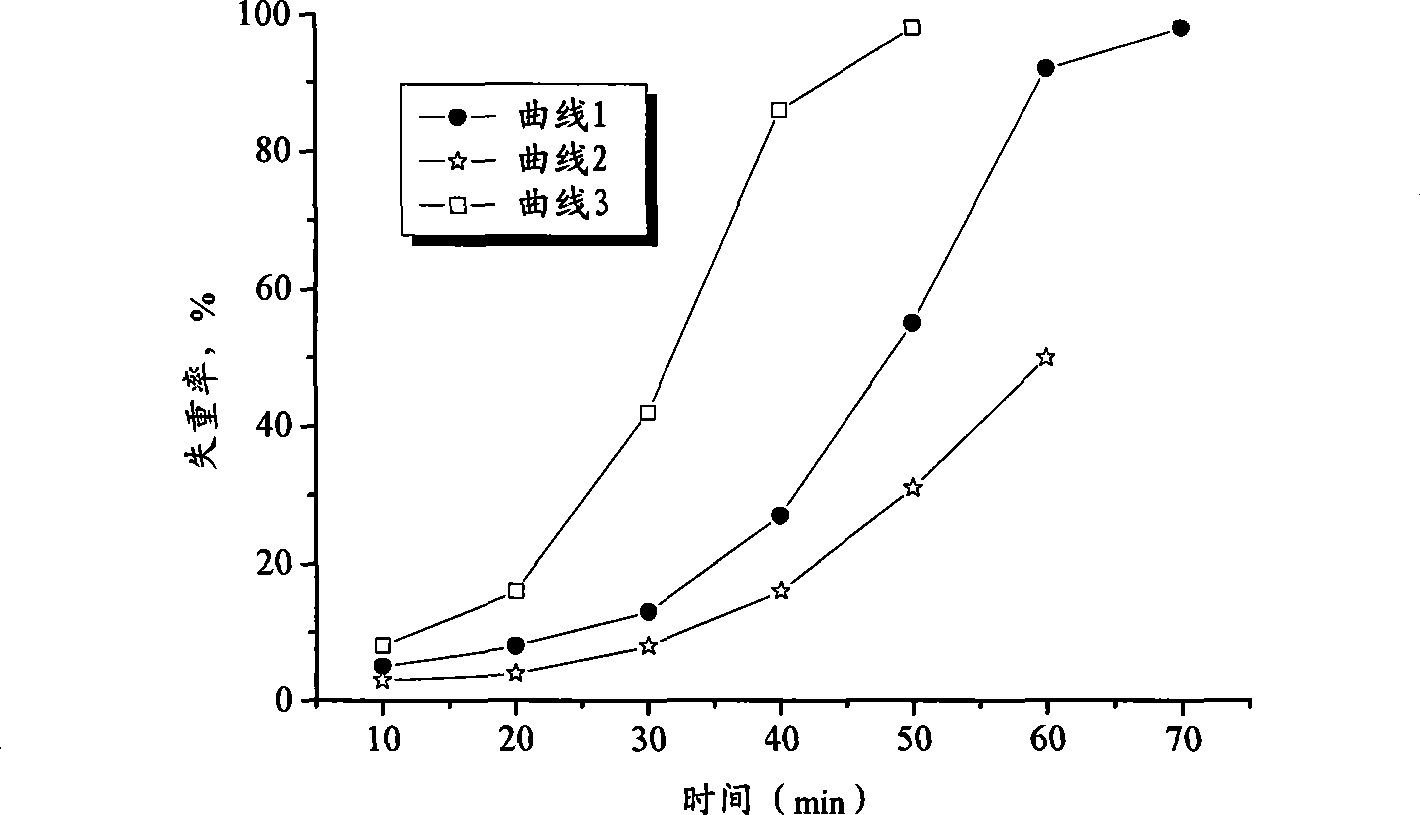

[0033] Suede gray fabric needs a series of post-finishing to form a suede surface with a powdery texture and a "writing effect", which is related to the selection of raw materials for the velvet yarn. As the base fabric of weft-knitted suede, there are two requirements. First, a tight ground structure is required. The fiber requires thicker monofilaments, and the effect of high-shrinkage fibers is better for the ground structure. Second, fabric suede requires the selection of fibers with finer monofilament deniers. The more fluffs on the surface of the suede fabric, the finer the fineness, and the stronger the simulation of the appearance of the fabric. The relationship between the fineness of the monofilament and the effect of the suede is shown in Table 1-1:

[0034] Table 1-1 Relationship between monofilament finenes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com