Nano-fiber covering yarn electrostatic spinning device and application thereof

A nanofiber and core-spun yarn technology is applied in the field of nanofiber devices, which can solve the problems of random arrangement of nanofibers, limited application scope, difficult processing, etc., and achieves the effect of a wide range of applicable materials and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

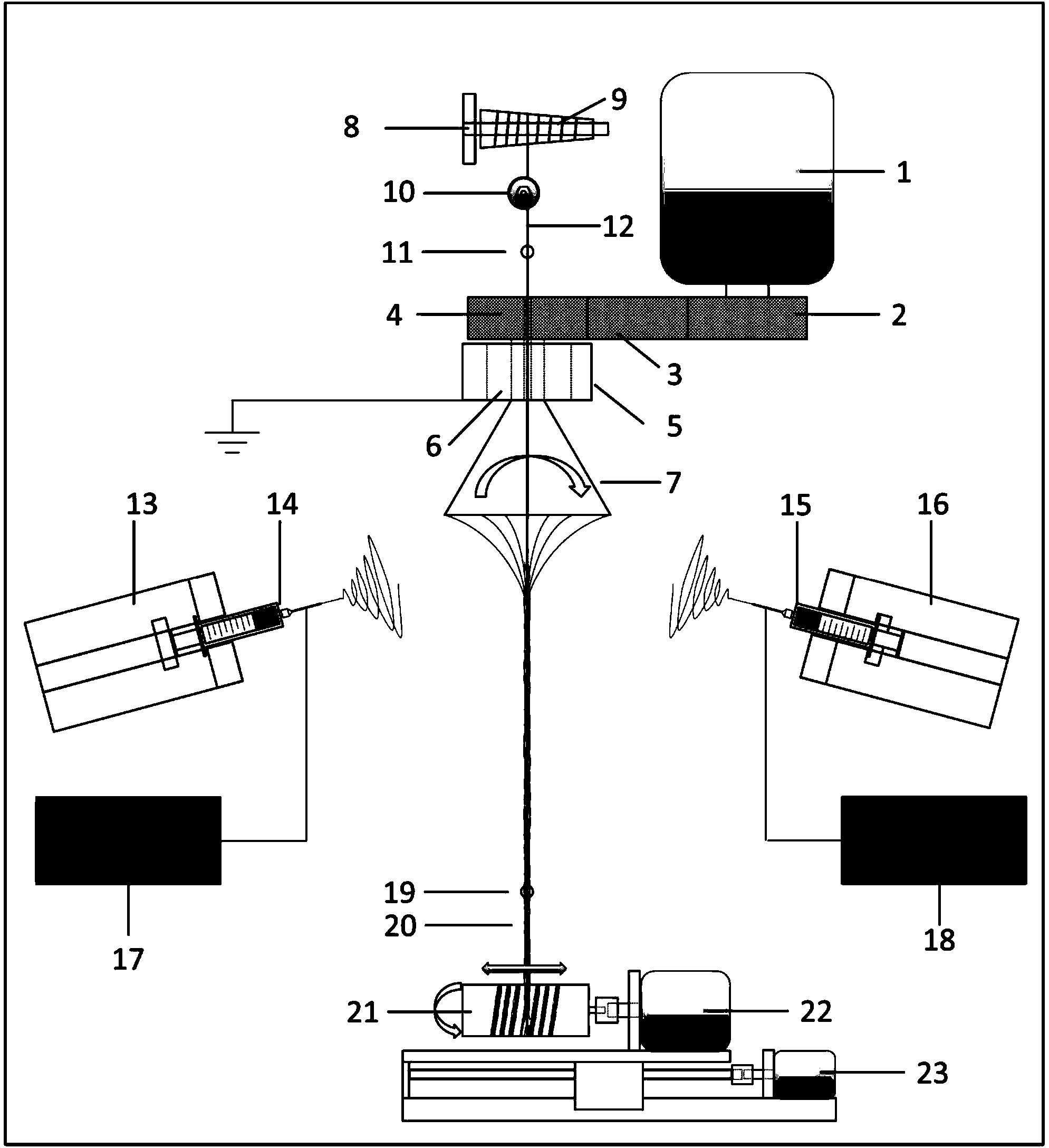

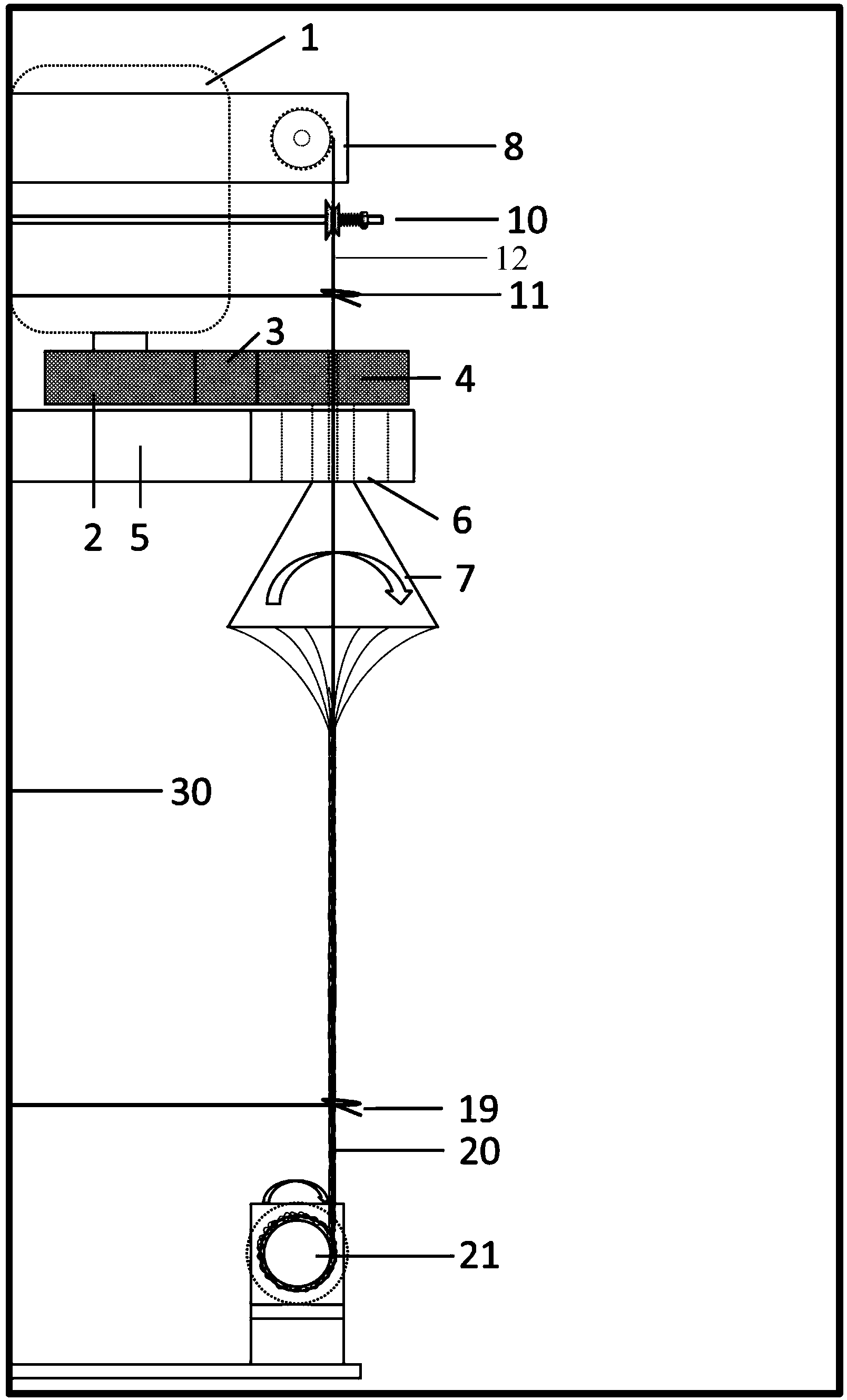

[0031] Such as figure 1 with 2 As shown, the device for preparing the electrospun nanofiber core-spun yarn includes a twisting device, an unwinding device, a winding device, a double-needle electrospinning device and a control system.

[0032] The twisting device includes a motor 1, a driving wheel 2, a belt 3, a driven wheel 4, a stand 5, a bearing 6, and a metal funnel 7; wherein, the rotation of the motor 1 drives the driving wheel 2 to rotate, and the driving wheel 4 is driven by the belt 3 to rotate. The metal funnel 7 is fixed on the stand 5 through the bearing 6, and the driven wheel 4 is integrated with the metal funnel 7 to drive the metal funnel 7 to rotate; the metal funnel 7 is grounded.

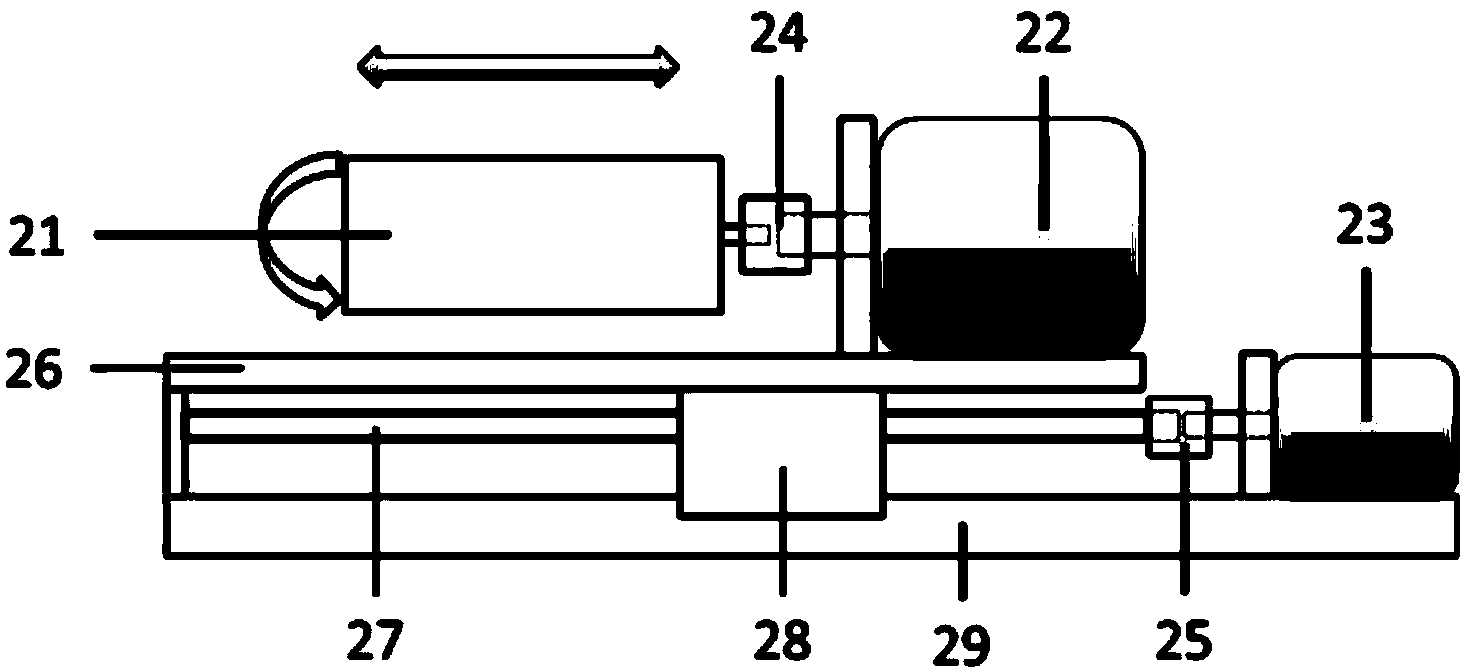

[0033] The unwinding device includes a creel 8, a bobbin 9, a tension clamp 10, and a yarn guide hook 11; the winding device includes a yarn guide hook 19, a winding roller 21, a winding motor 22, a traverse motor 23, a screw 27. Slide block 28, shaft coupling 24, 25, frame pl...

Embodiment 2

[0038]0.8 g of polycaprolactone (PCL) was accurately weighed and added to 10 ml of hexafluoroisopropanol, and stirred to obtain a PCL solution with a mass volume ratio of 8%. Add the PCL solution into two syringes respectively, and use a double-needle spinning device for spinning. The distance between the two needles is 24 cm, and the voltage of the high-voltage generator is -12 kV and +12 kV respectively; polylactic acid (PLA) long The silk is drawn from the bobbin through the yarn guide hook, the inner hole of the funnel, and the yarn guide hook, and is wound on the winding roller. The winding speed is 25 cm / s, and the traverse speed is 2 cm / min; the outer diameter of the metal funnel is 10 cm, the bevel angle of the funnel is 45°, and the rotation speed is 500 rpm. The PCL solution is drawn and thinned under the action of a high-voltage electrostatic field to form nanofibers, which are placed on the outer edge of the metal funnel and the PLA yarn to form a fiber mesh funnel...

Embodiment 3

[0040] Accurately weigh 1.6 grams of regenerated silk fibroin (SF) and 0.4 grams of polyethylene oxide (PEO) into 20 milliliters of deionized water, and stir to obtain an SF / PEO solution with a mass-volume ratio of 10%. Add 2.4 mg of bone morphogenetic protein-2 (BMP-2) to 10 ml of SF / PEO solution, and stir to obtain a homogeneous spinning solution A. Add 0.2 g of nano-hydroxyapatite with an average particle size of 50-150 nm to 10 ml of SF / PEO solution, and stir to obtain a uniform spinning solution B. Add the spinning solutions A and B into two syringes respectively, and use a double-needle spinning device for spinning. The distance between the two needles is 24 cm, and the voltage of the high-voltage generator is -18 kV and +18 kV respectively; degumming the silk The filament is drawn from the bobbin through the yarn guide hook, the inner hole of the funnel, and the yarn guide hook, and is wound on the winding roller at a winding speed of 10 cm / s; the outer diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com