Process flow for removing CO2 and H2S in gas mixture

A technology of process flow and mixed gas, which is applied in the comprehensive purification treatment of shift gas in methanol production and in the field of comprehensive purification treatment of shift gas in the production of synthetic ammonia and co-production of urea, which can solve the problem of high device operating costs, large equipment investment, and inability to apply sulfur Recycling and other issues to achieve the effect of recycling and improving economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

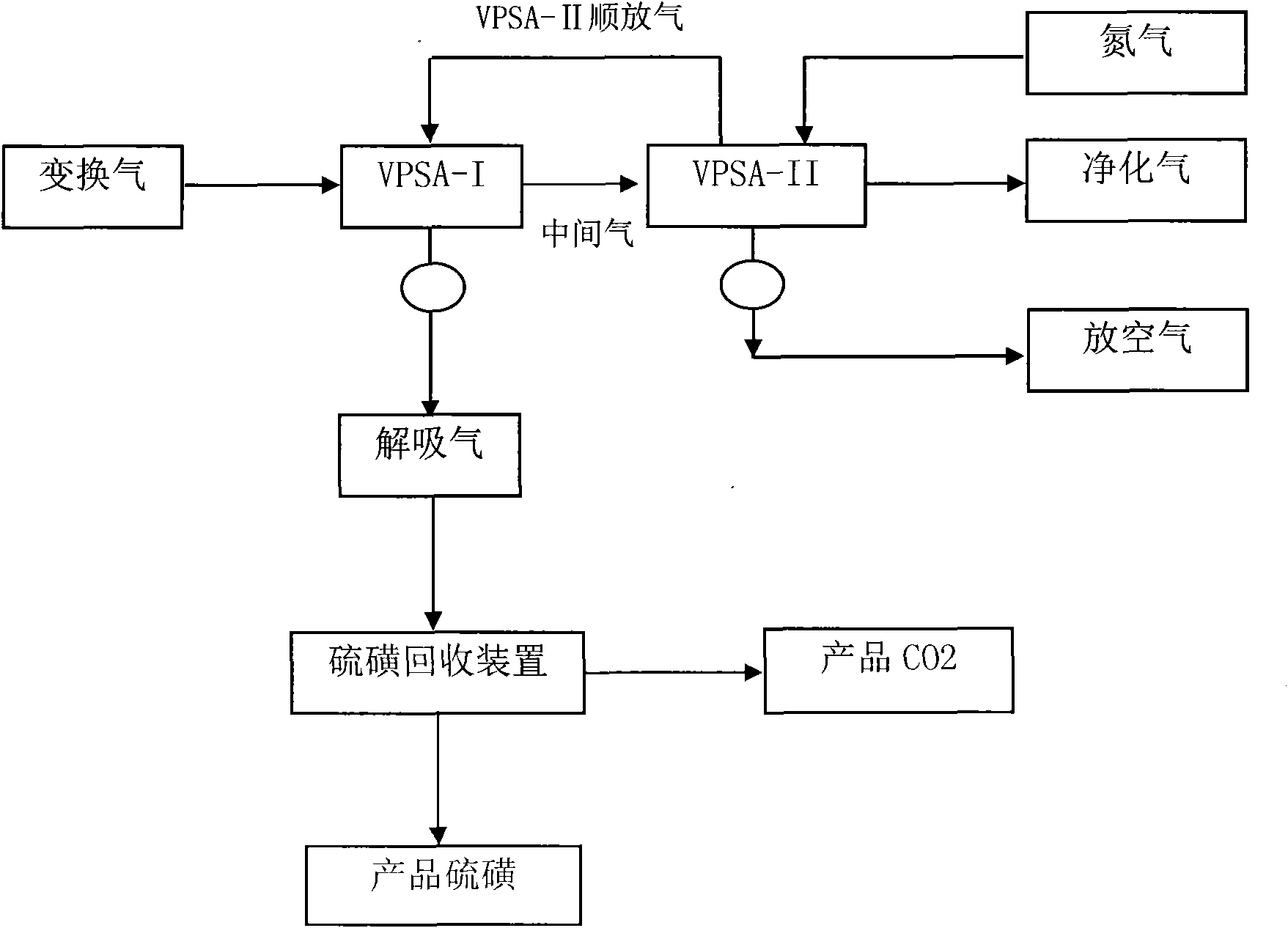

[0015] Taking the shift gas in the process of coal gasification to synthesize ammonia and co-produce urea as the mixed gas to be purified, and its purification process as an example, combined with figure 1 The present invention will be described.

[0016] A synthetic ammonia co-production urea unit using coal as raw material, the composition (v / v) of the shift gas is: CO 2 27.5%, CO 1.5%, H 2 54%, CH 4 0.8%, N 2 16%; H 2 S content: ≤240mg / Nm 3 . The shifted gas is purified by the first stage of vacuum pressure swing adsorption VPSA-I, and the formed intermediate gas enters the second stage of vacuum pressure swing adsorption VPSA-II. CO in intermediate gas 2 The concentration is about 4.6-7.4%, and the removed CO 2 and H 2 S forms desorbed gas by reverse discharge and vacuuming, and in the desorbed gas, CO2 The concentration is about 98.0%. Use H 2 S selective oxidation catalyst for desorbing H in gas 2 S is subjected to selective catalytic oxidation treatment,...

Embodiment 2

[0019] Taking the mixed gas composed of shifted gas and unshifted water gas in the coal gasification to methanol process as the mixed gas to be purified, and the process of purifying it as an example, combined with figure 1 The present invention will be described.

[0020] A coal-to-methanol plant uses Texaco coal-water slurry gasification to produce water gas, and then undergoes partial conversion and gas purification to synthesize methanol. The mixed gas (mixed with converted gas and unconverted crude gas) entering the purification section is as follows (v / v): H 2 43.8%, CO 19.1%, CO 2 34.4%, H 2 S 1.3%, other 1.4%. The purification section adopts the mixed gas provided by the present invention to remove CO 2 、H 2 S craft. First, the shifted gas is purified by the first stage of vacuum pressure swing adsorption VPSA-I, and the formed intermediate gas enters the second stage of vacuum pressure swing adsorption VPSA-II to control the CO in the intermediate gas. 2 Conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com