Method for extracting valuable metal from seabed multi-metal sulfide mineral coupling complex ore

A technology for valuable metals and sulfide ores, applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of high speed, low consumption of raw materials, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

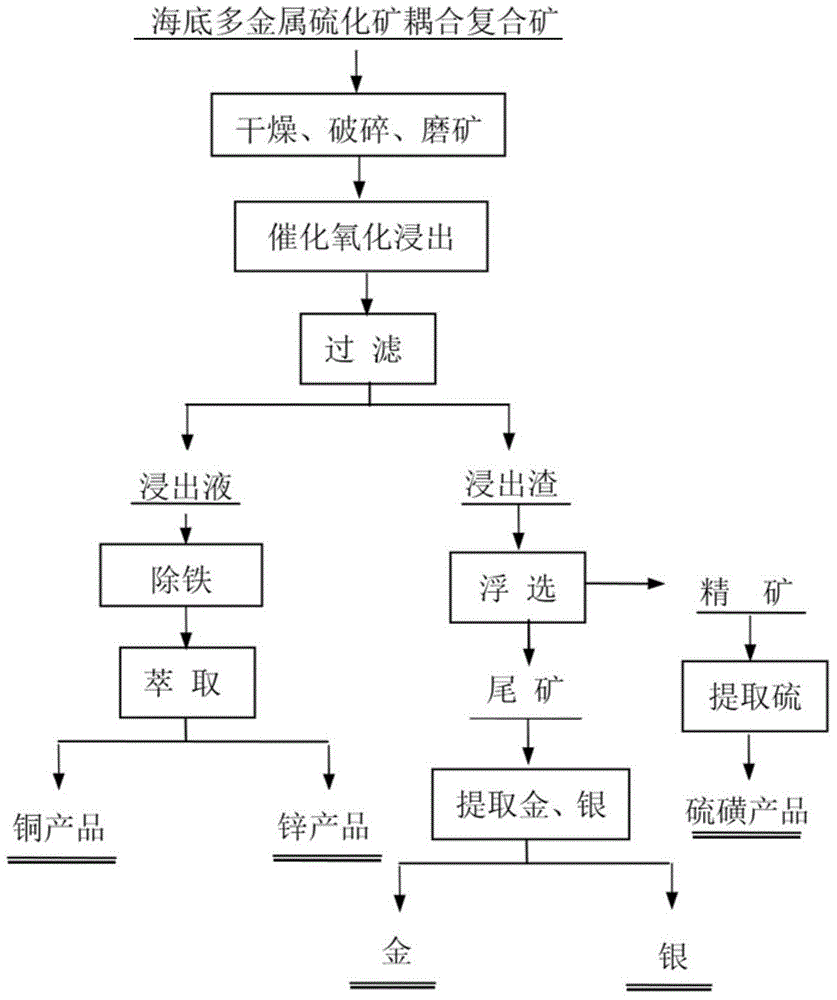

[0061] Such as figure 1 As shown, a method for extracting valuable metals from seabed polymetallic sulfide ore coupled composite ore, comprising the following steps:

[0062] (1) Catalytic oxidative leaching: dry the seabed polymetallic sulfide ore coupling compound ore, then crush and ball mill to obtain -100 mesh composite mineral powder, place the composite mineral powder in the reaction vessel, add leaching agent, Catalysts and oxidants carry out the catalytic oxidation leaching reaction of materials, so that valuable elements such as copper and zinc in the composite ore are leached efficiently and enter the leach solution; sulfur, gold and silver in the composite ore enter the leaching residue, thereby being enriched. Specifically, first add 400ml [H + ] concentration is 4.5mol L -1 sulfuric acid solution; then, add -100 mesh 100g composite ore into the reactor, and add 3g of copper sulfate as a catalyst to the reactor at the same time, set the leaching temperature to ...

Embodiment 2

[0067] Such as figure 1 As shown, a method for extracting valuable metals from seabed polymetallic sulfide ore coupled composite ore, comprising the following steps:

[0068] (1) Catalytic oxidative leaching: dry the seabed polymetallic sulfide ore coupling compound ore, then crush and ball mill to obtain -100 mesh composite mineral powder, place the composite mineral powder in the reaction vessel, add leaching agent, Catalysts and oxidants carry out the catalytic oxidation leaching reaction of materials, so that valuable elements such as copper and zinc in the composite ore are leached efficiently and enter the leach solution; sulfur, gold and silver in the composite ore enter the leaching residue, thereby being enriched. Specifically, first add 500ml [H + ] concentration is 5.0mol L -1 Then, add -100 mesh 100g composite ore into the reactor, and add 5g of copper sulfate as a catalyst into the reactor at the same time, set the leaching temperature to 90°C, turn on the leac...

Embodiment 3

[0073] Such as figure 1 As shown, a method for extracting valuable metals from seabed polymetallic sulfide ore coupled composite ore, comprising the following steps:

[0074] (1) Catalytic oxidative leaching: dry the seabed polymetallic sulfide ore coupling composite ore, then crush and ball mill to obtain -100 mesh composite mineral powder, place the composite mineral powder in a reaction vessel, and add a leaching agent into the reaction vessel , Catalyst and oxidant to carry out the catalytic oxidation leaching reaction of the material, so that the valuable elements such as copper and zinc in the composite ore can be leached efficiently and enter the leachate; the sulfur, gold and silver in the composite ore enter the leaching slag to be enriched. Specifically, first add 300ml [H + ] concentration is 4.5mol L -1 Then, add -100 mesh 100g composite ore into the reactor, and add 8g of copper sulfate as a catalyst into the reactor at the same time, set the leaching temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com