Technology and device for recovering volatile tail gas in sulfur collection pit of sulfur device of oil refinery

A sulfur device and tail gas recovery technology, which is applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of incinerator energy consumption, environmental pollution, and the inability to recover volatile tail gas sulfur, etc., so as to reduce the concentration and reduce the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A process for recovering volatile tail gas in a sulfur collection pit of a sulfur plant in an oil refinery, which is carried out according to the following steps:

[0017] (1) The volatile tail gas and elemental sulfur from the sulfur pit are condensed by the water jacket, the elemental sulfur returns to the sulfur pit, the volatile gas enters from the upper part of the supergravity settling reactor, the gas is sucked into the reactor, and passes through the high-speed centrifugal liquid and the stator rectification mechanism Segmentation, the gas is sheared and broken into micro-bubbles and evenly dispersed in the desulfurization solution, so that rapid mass transfer, absorption and oxidation reactions occur between the gas-liquid two phases. The desulfurization solution absorbs the hydrogen sulfide in the gas phase into the liquid phase to generate divalent sulfide ions; the catalyst oxidizes the divalent sulfide ions into elemental sulfur. The main components of the ...

Embodiment 2

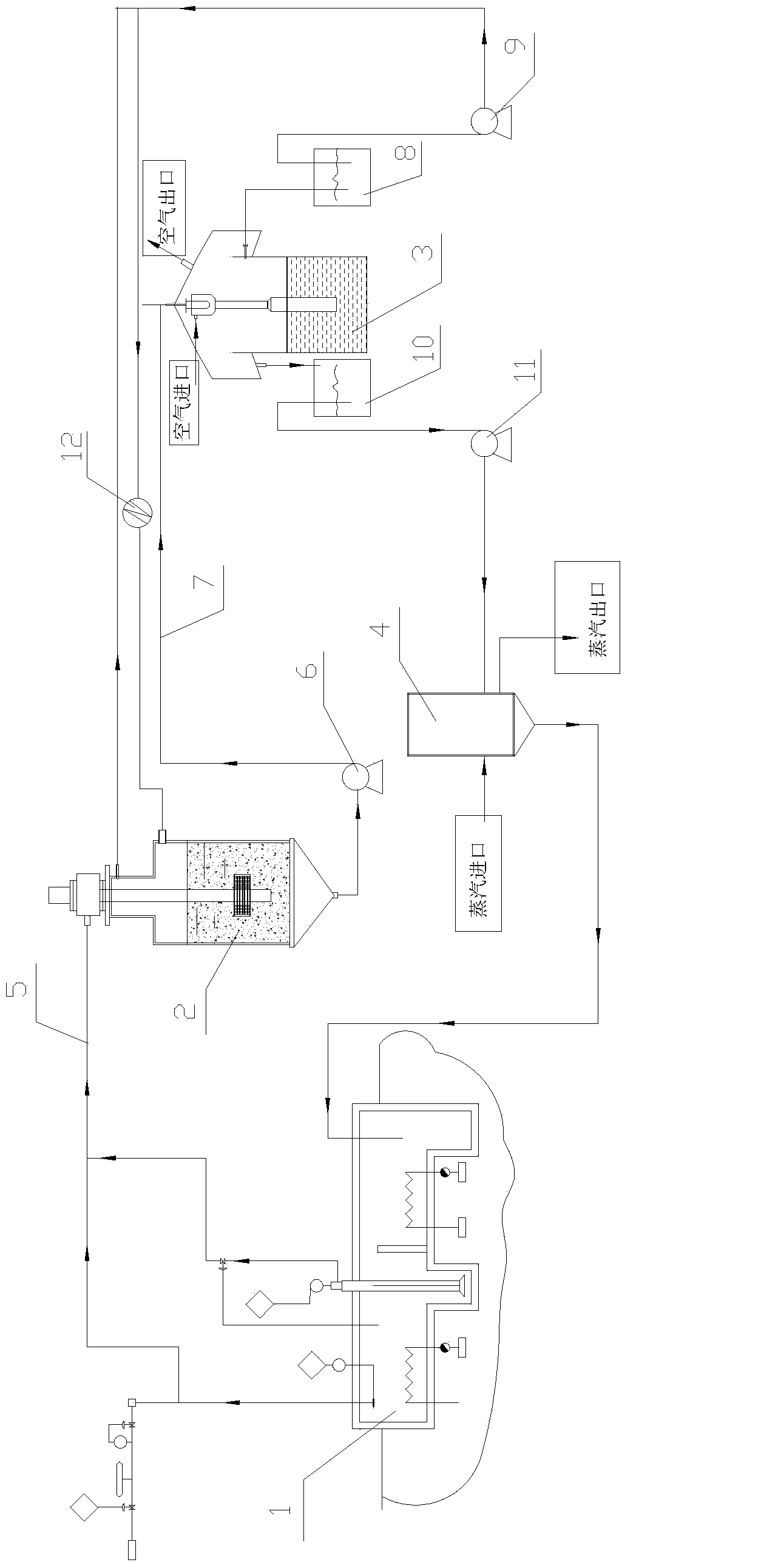

[0022] This embodiment is a recovery device for volatile tail gas in the sulfur collection pit of a sulfur plant in an oil refinery. The equipment is connected as follows: figure 1 As shown, it includes a high-gravity reactor 2, a spray regenerator 3 and a sulfur melting tank 4; the air inlet on the upper part of the high-gravity reactor is connected to the volatile tail gas of the sulfur collection pit 1 and the Elemental sulfur outlet, the liquid outlet at the bottom of the supergravity reactor 2 is connected to the rich liquid inlet at the upper part of the jet regenerator 3 through the rich liquid outlet pipe 7 provided with the rich liquid pump 6, and the upper part of the supergravity reactor 2) The outlet of the purified gas is connected to the incinerator through a pipeline; the lean liquid outlet of the injection regenerator 3 is connected to the desulfurization lean liquid tank 8 through a pipeline, and the desulfurization lean liquid tank 8 is connected to the superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com