Method for removing sulfide from oil products with high aromatic hydrocarbon content

A sulfide, high-content technology, applied in the field of removing sulfides in high-content aromatic oil products, achieves the effects of mild reaction conditions, simple method and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

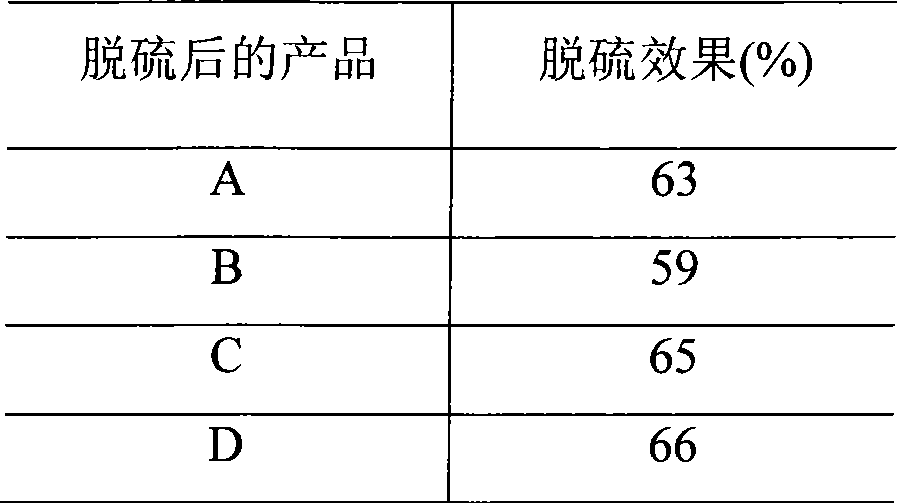

example 1

[0026] A mixture with a molar concentration ratio of formic acid and phosphoric acid of 1:1 and a H2O2 solution with a concentration of 30% are prepared to obtain a catalytic oxidation mixture. The catalytic oxidation mixture is mixed with the oil in a volume ratio of 1:2, and the reaction system is placed in a tank ultrasonic generator with a frequency of 40kHz. After reacting at 60°C for 20 minutes, it is carried out in cooling water at 10°C. After cooling and demulsification, 0.1% KCl is added to the emulsion that has undergone preliminary demulsification treatment for demulsification, and the separation of oil and water is realized after centrifugation. Then, two extractions are carried out with a mixed extractant whose volume ratio of solvent to oil is 2:1 to obtain product A after desulfurization.

Embodiment 2

[0028] Compared with Example 1, the frequency of the ultrasonic wave is adjusted to 80 kHz, and the amount of other materials and operating conditions are the same as those of Example 1, and the desulfurization product B is obtained.

Embodiment 3

[0030] Compared with Example 1, the frequency of the ultrasonic wave is adjusted to 1000 kHz, and the amount of other materials and operating conditions are the same as those in Example 1, to obtain a desulfurization product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com