Process for removing organic sulfur in low-temperature condition

A technology of low temperature conditions and process methods, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of inability to recover sulfur element and inability to regenerate solid catalysts, and achieve low operating costs, simple operation, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

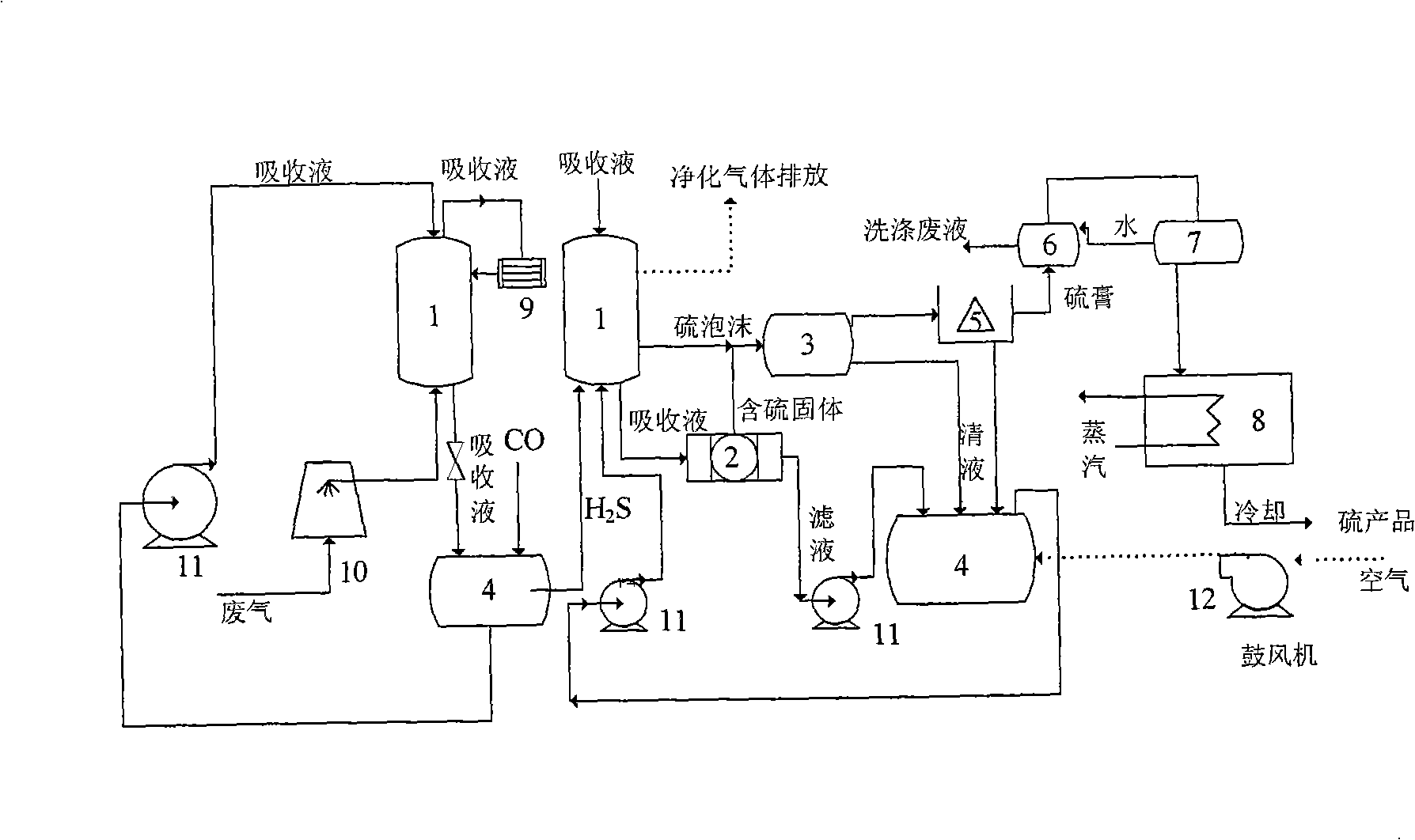

Method used

Image

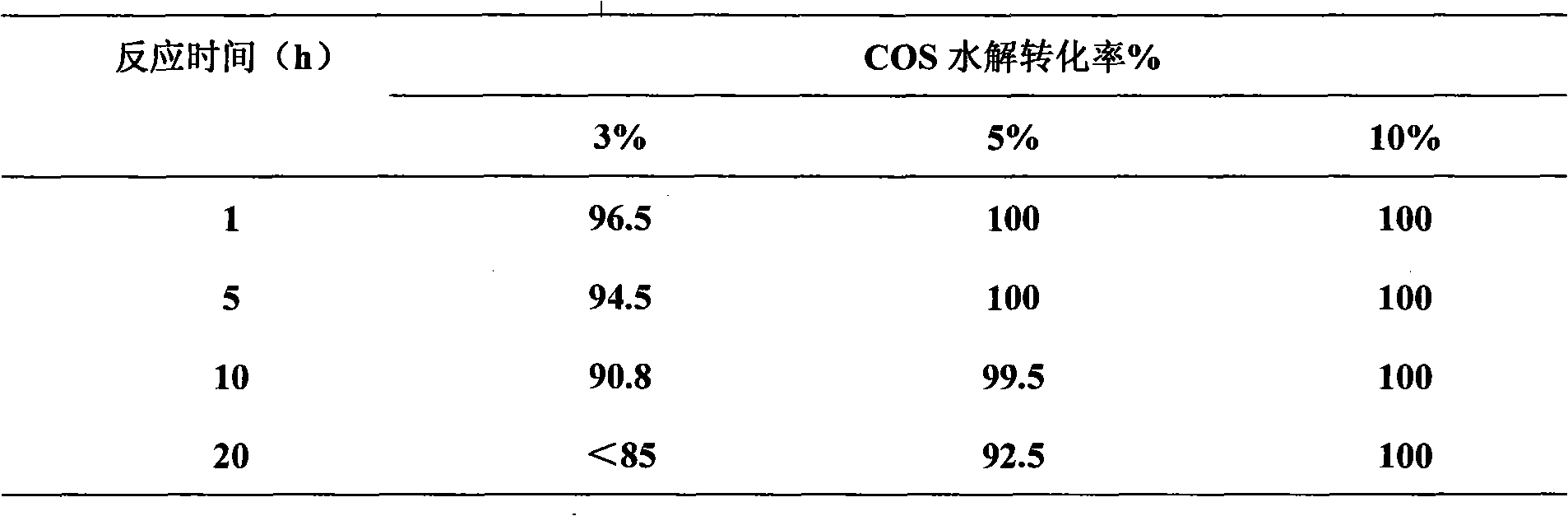

Examples

Embodiment 1

[0030] 1. Preparation of absorption liquid:

[0031] 1. Organic sulfur absorption solution and its preparation: 5ml of hexahydropyridine (chemically pure), 50ml of ethanol (chemically pure), 1ml of KOH with a concentration of 1mol / L and distilled water were prepared into 100ml of organic sulfur absorption solution for use.

[0032] 2. Regenerated gas H 2 Preparation of S absorption solution: weigh 1.62 grams of FeCl 3 and 0.72 g of 50% Mn(NO 3 ) 2 solution (element molar ratio Mn:Fe=0.2), dissolved together in 200mL deionized water, fully stirred and dissolved to make Fe 3+ Concentration is the composite ion absorption liquid of 0.05mol / L; Add 2.92 grams of EDTA and 2.18 grams of sulfosalicylic acid as stabilizer (metal ion Fe 3+ and the total molar ratio of the stabilizer is 1:2); with NaCO 3 and NaHCO 3 Control the pH of the solution to 9, and set it aside.

[0033] 2. The process steps of low temperature organic sulfur removal are:

[0034] 1. After cooling the sulf...

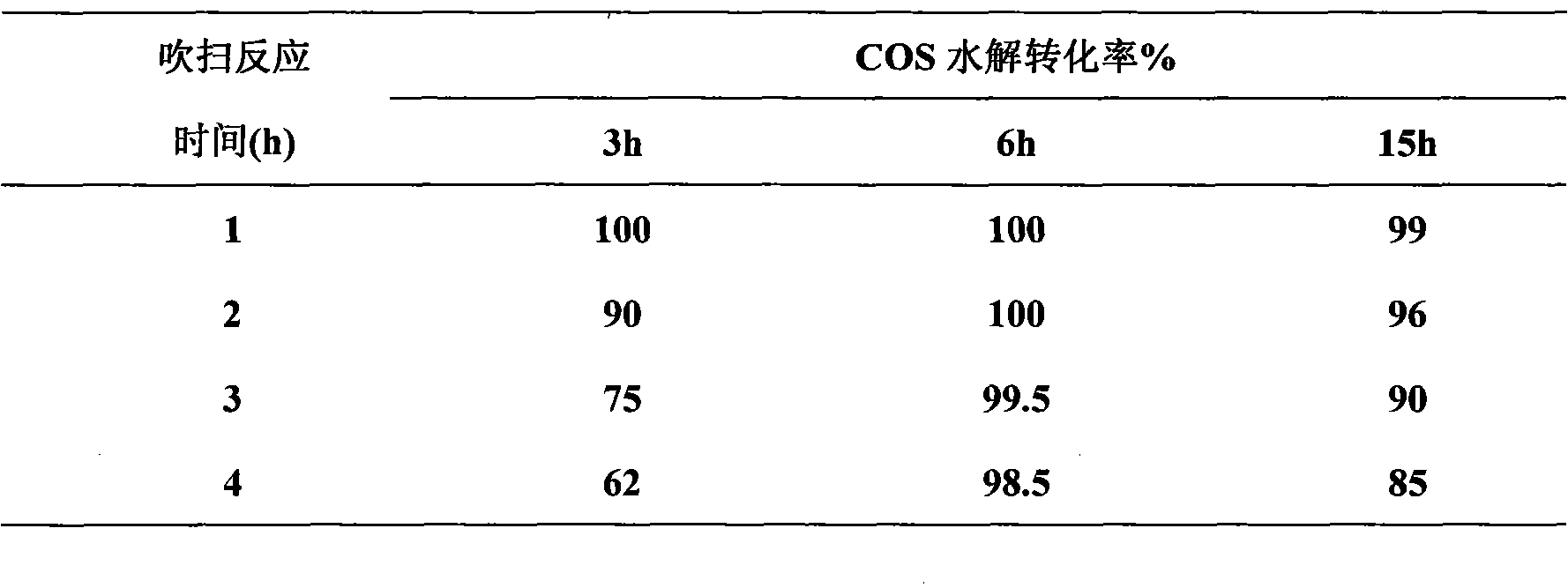

Embodiment 2

[0039] 1. Preparation of absorption liquid:

[0040] 1. Organic sulfur absorption solution: mix 10ml of hexahydropyridine, 50ml of ethanol, and 1ml of Na with a concentration of 1mol / L 2 CO 3 Prepare 100ml of organic sulfur absorption solution with distilled water and set aside.

[0041] 2. Regenerated gas H 2 S absorption solution: Weigh 1.62 grams of FeCl 3 and 0.87 g of Mn(CH 3 COO) 2 Dissolve in 200mL deionized water (element molar ratio Mn:Fe=0.5), fully stir and dissolve to make Fe 3+ Concentration is the solution of 0.05mol / L; Add 4.36 grams of sulfosalicylic acid and 5.84 grams of EDTA as stabilizer (metal ion Fe 3+ and the total molar ratio of the stabilizer is 1:4); with NaCO 3 and NaHCO 3 Control the pH of the solution to 10.

[0042] 2. The process steps of low temperature organic sulfur removal are:

[0043] 1. After cooling the sulfur-containing exhaust gas, that is, the exhaust gas with COS2 S and CO 2 , and absorb H 2 S;

[0044] 2. Pass regenerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com