Method for nano sulfur atomization synthesis

A technology of nano-sulfur and chemical synthesis, applied in the preparation/purification of sulfur, etc., can solve the problems of inconvenient mass production and continuous preparation, difficult control of morphology consistency, high energy consumption, etc., to achieve good morphology consistency and increase reaction time, the effect of increasing the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

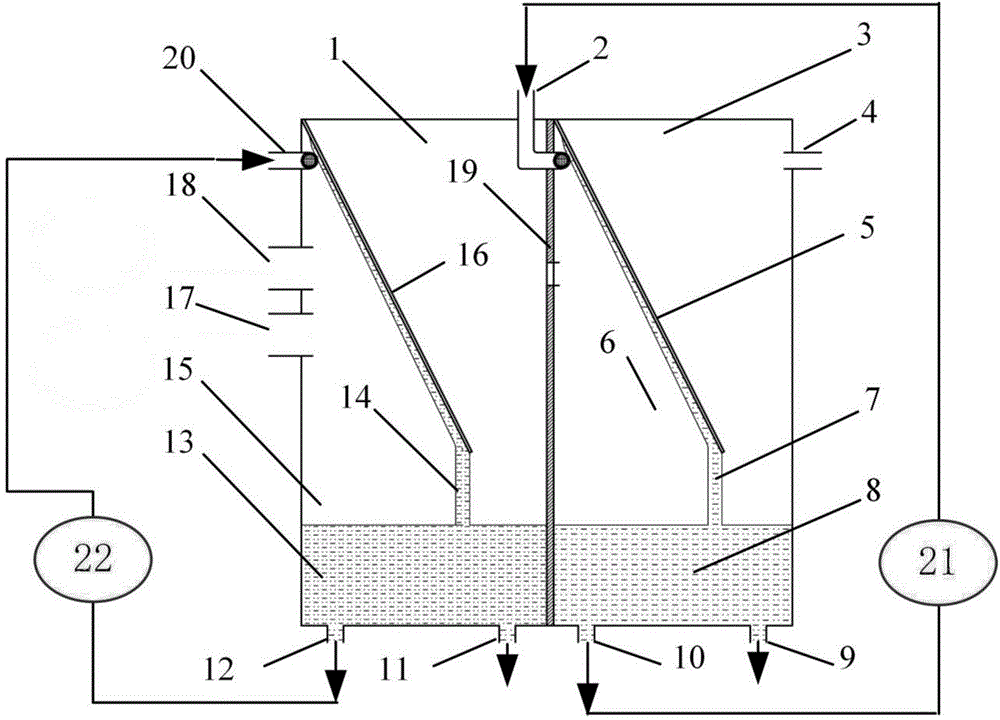

Method used

Image

Examples

Embodiment 1

[0064] Starting raw material sodium thiosulfate (Na 2 S 2 o 3 ) and the hydrochloric acid whose mass fraction is 34%~36% of the precipitating agent are prepared respectively into the aqueous solution that the molar concentration is 0.01mol / L, 0.02mol / L, and the molar concentration ratio of the two is Na + :H + =1:1. Adjust the air flow of the nebulizer to 1L / min. Fill the reactor with about 250mL of buffer solution and recovery solution, start the recovery liquid flow pump and buffer solution flow pump; start the air pump to uniformly atomize the starting material solution and precipitant solution, and monitor the pH of the buffer solution at 5-6 and recovery Solution pH=12~14, after the atomization is completed, centrifuge the obtained buffer solution to obtain the nano-sulfur precipitation product, wash it with water and alcohol for 3 to 5 times until the washing solution is neutral, test for Na + Concentration ≤ 10ppm, and then drying under negative pressure at 100°C f...

Embodiment 2

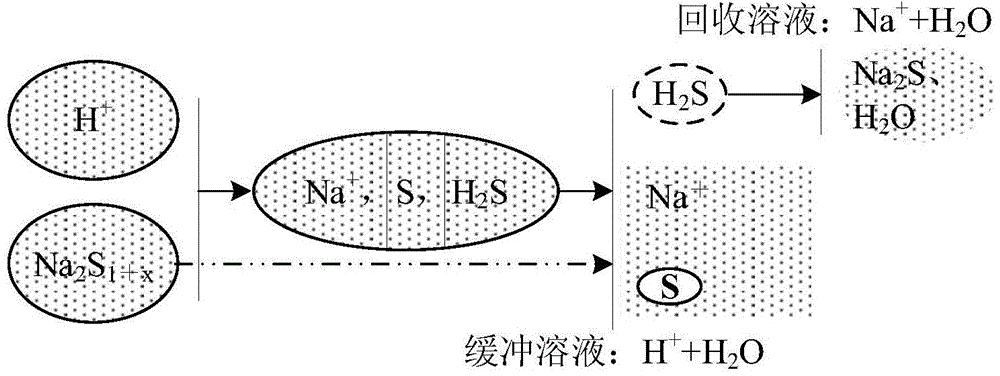

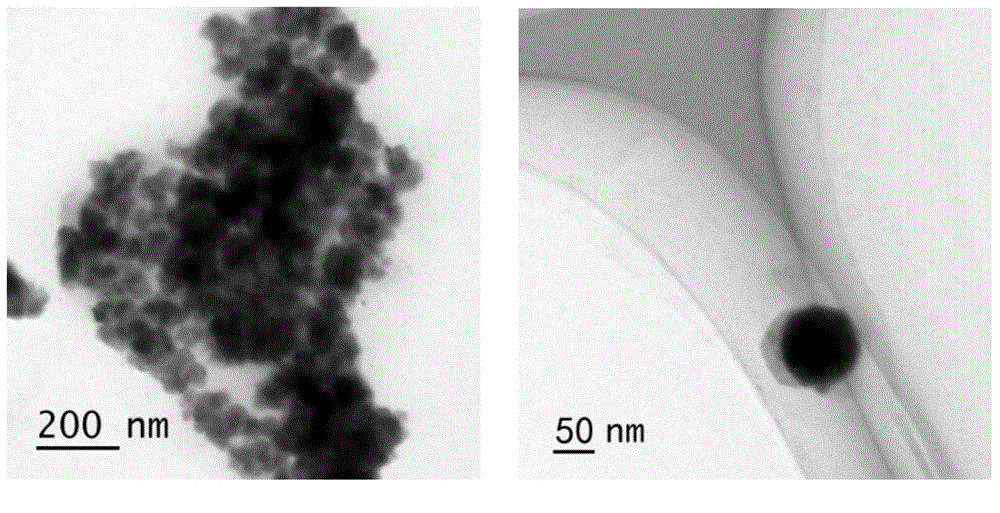

[0066] The starting material sodium sulfide is dissolved in water to form a 0.25mol / L aqueous solution, and then the molar ratio of Na + : S=1: (0.8~1.5) add sublimated sulfur, stir at room temperature for 4~6h, filter the precipitate to form sodium polysulfide (Na 2 S 1 +x ) transparent solution, the mass fraction is 34% ~ 36% hydrochloric acid diluted with deionized water to obtain a 0.5mol / L precipitant solution, the molar concentration ratio of the two is Na + :H + =1:1.1. Adjust the air flow of the nebulizer to 5 L / min. Fill the reactor with an appropriate amount (the liquid level is about 15mm to 25mm) of buffer solution and recovery solution, start the recovery liquid flow pump and the buffer solution flow pump; start the air pump to uniformly atomize the starting material solution and the precipitant solution, and monitor The pH of the buffer solution is 5-6 and the pH of the recovery solution is 12-14. After the atomization is completed, the obtained buffer solut...

Embodiment 3

[0068] The starting raw material sodium sulfide is dissolved in water to form a 0.1mol / L aqueous solution, and then the molar ratio of Na + : S=1: (0.8 ~ 1.5) add sublimated sulfur, stir at room temperature for 4 ~ 6h, filter the precipitate, and form transparent sodium polysulfide (Na 2 S 1+x , x=0.7~1.4) solution, dilute formic acid with deionized water to obtain 0.2mol / L precipitant solution, the molar concentration ratio of the two is Na + :H + =1:1.2. Adjust the air flow of the nebulizer to 1.5 L / min. Fill the reactor with about 450mL of buffer solution and recovery solution, start the recovery liquid flow pump and the buffer solution flow pump; start the air pump to uniformly atomize the starting material solution and the precipitant solution, and monitor the pH of the buffer solution = 5-6 and recovery Solution pH=12~14, after the atomization is completed, the obtained buffer solution is centrifuged to obtain the nano-sulfur precipitation product, which is washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com