Method for desulphurizing methyl tertiary butyl ether with high sulphur content

A technology with high sulfur content of methyl tert-butyl ether, applied in the fields of ether preparation, ether separation/purification, organic chemistry, etc., can solve problems such as MTBE production difficulties, and achieve the effects of low cost, excellent product quality and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

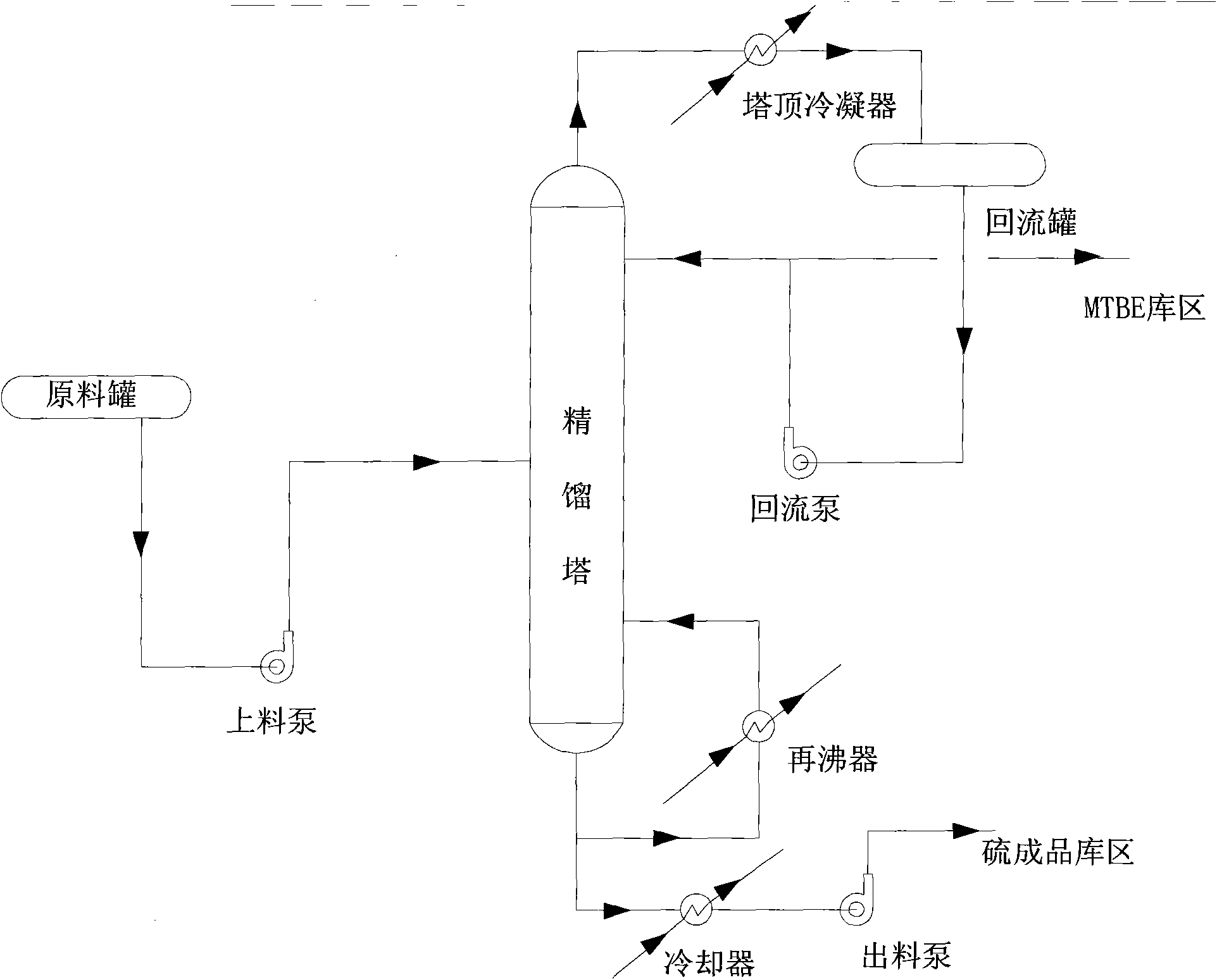

Image

Examples

Embodiment

[0026] Example: Pilot test

[0027] (1) Pilot scale

[0028] MTBE processing capacity is 30,000 tons / year

[0029] (2) Brief description of the process flow

[0030] The MTBE raw materials in the storage area are pumped to the buffer tank of the device by the feeding pump, and then pumped out into the distillation column, and heated to 90℃~120℃ through the reboiler, the temperature at the top of the tower is 69℃~75℃, and the gas phase at the top of the column passes through the cooler After cooling, it enters the reflux tank. The materials in the reflux tank are pumped out by the reflux pump, part of which is refluxed at the top of the tower, and the other part of the qualified products enters the finished product tank in the storage area. The bottom of the tower contains very little MTBE sulfur products. Zone S storage tank (cooled to below 40℃ after cooler), steam power 1.0MPa steam to provide heat, this MTBE product is colorless and transparent, which is better than the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com