Separating agent for separating sulfur from sulfur-containing system and method for separating sulfur

A separation agent and system technology, applied in the field of sulfur separation, can solve the problems of small sulfur elemental particles, difficulty in sedimentation, sulfur waste, etc., and achieve the effects of easy sedimentation and separation, low volatility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] (1) Take 60mL of the iron-based ionic liquid prepared in (1), add 30mL of DMI, 0.6mLTX-100 into it, and mix well to obtain the separating agent;

[0100] (2) Raise the temperature of the separating agent prepared in step 1 to 80°C, and add 2 Sulfur-containing system after S;

[0101] (3) Cool the system obtained in step 2 to room temperature naturally. After 20 minutes, crystals are precipitated in the sulfur-containing system, and the precipitated crystals are separated and recovered.

[0102] The average particle diameter of the obtained sulfur particles measured by the eyepiece micrometer of the microscope is 3.1 mm.

Embodiment 2

[0104] (1) Take 50 mL of the iron-based ionic liquid prepared in (1), add 25 mL of DMI and 0.5 mL of TX-100 into it, and mix well to obtain the separating agent;

[0105] (2) Pass into the separating agent that contains 1%H in the separating agent prepared in step 1 2 The gas mixture of S is allowed to stand to separate the sulfur.

[0106] The eyepiece micrometer of the microscope measures the average particle diameter of the obtained sulfur particles to be 3.2 mm, and its particle size distribution is as follows: Figure 4 shown.

experiment example

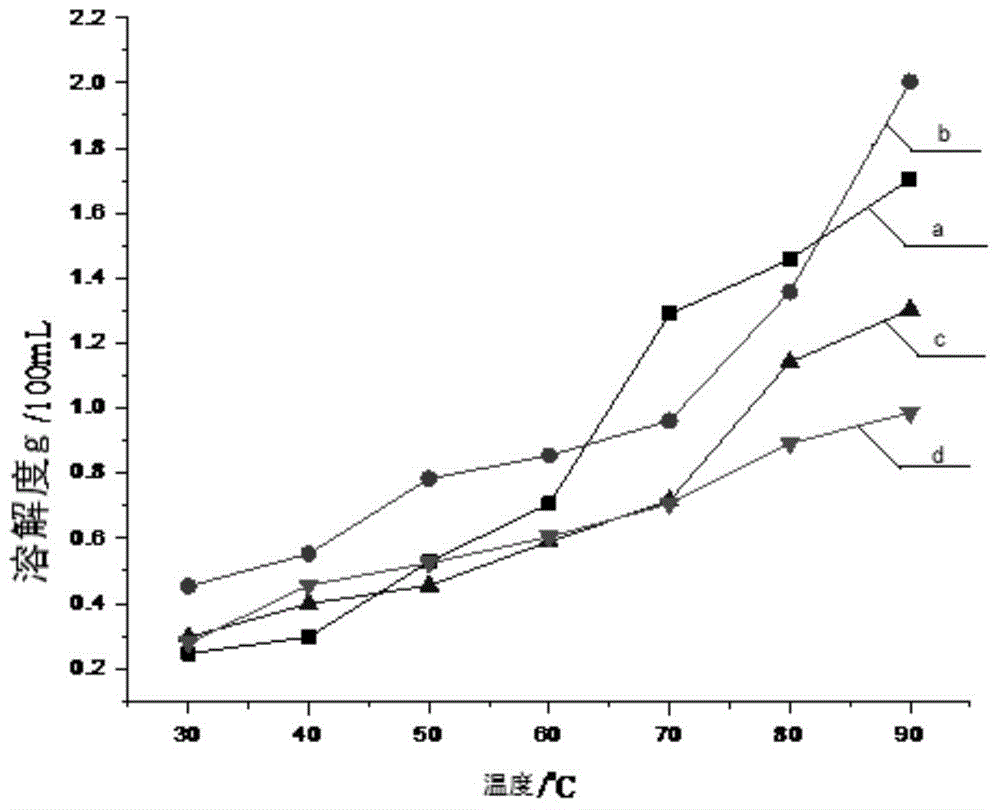

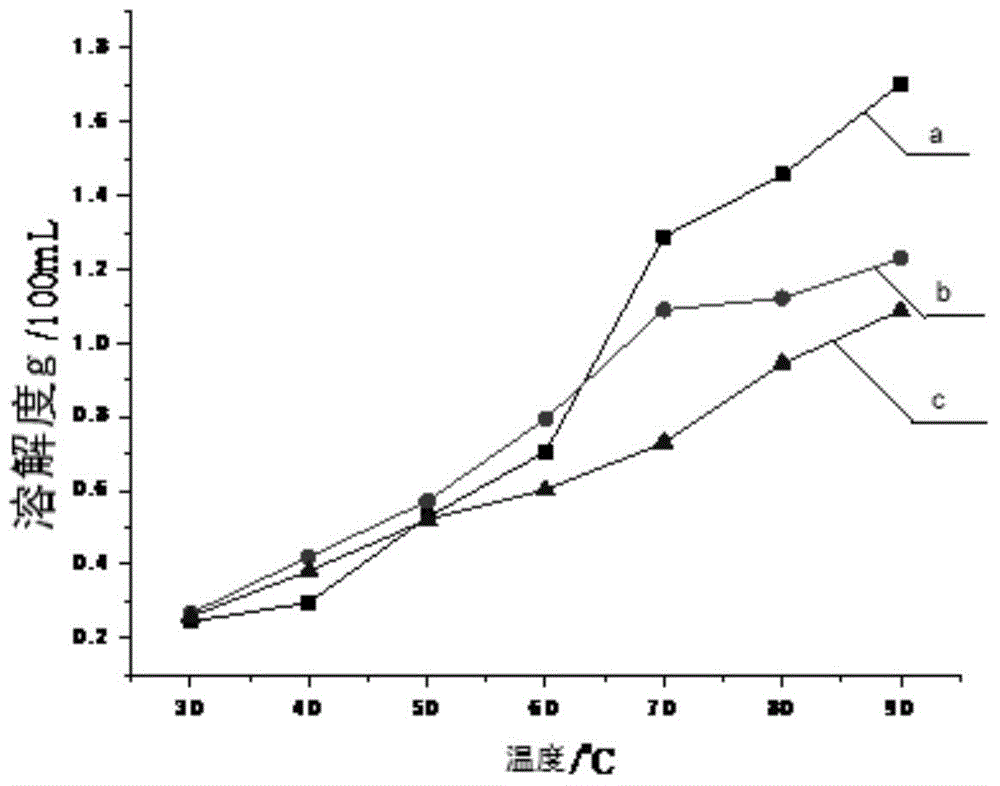

[0118] (2) Determination method of sulfur solubility:

[0119] (1) Take excess sulfur and add it to 20mL solvent system, stir at room temperature until the solution is balanced, then filter it with a G4 sand core funnel to obtain undissolved sulfur, wash it with deionized water three times, put it in a drying oven and dry it to constant weight, and the sulfur The difference between the added amount and the undissolved amount is the solubility x of sulfur in the solvent system at room temperature 0 ;

[0120] (2) Take excess sulfur and add it to 30mL solvent system, stir and heat to t°C until the dissolution balance, let it stand for 1h to make the undissolved sulfur layered at the bottom of the solution, take 20mL upper saturated solvent system into a small beaker, cool to At room temperature, until all the sulfur is crystallized, washed with filtered water for three times, and dried to constant weight, the amount of sulfur precipitated can be obtained as x t , so that the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com