Multi-plane dust removing device

A dust removal device and multi-plane technology, applied in power supply technology, electrostatic separation, etc., can solve problems such as short service life, short life, complex structure of dust removal device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

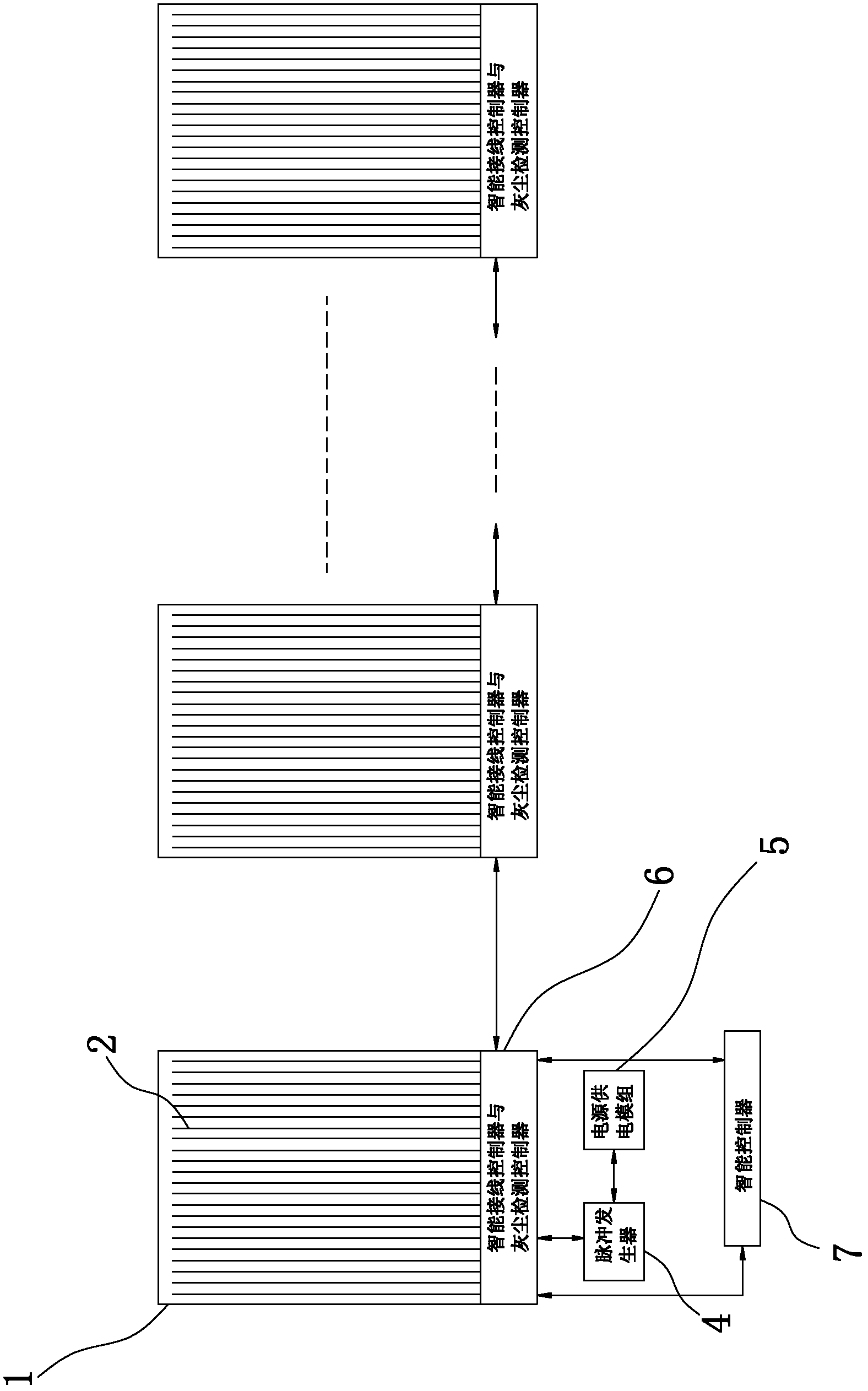

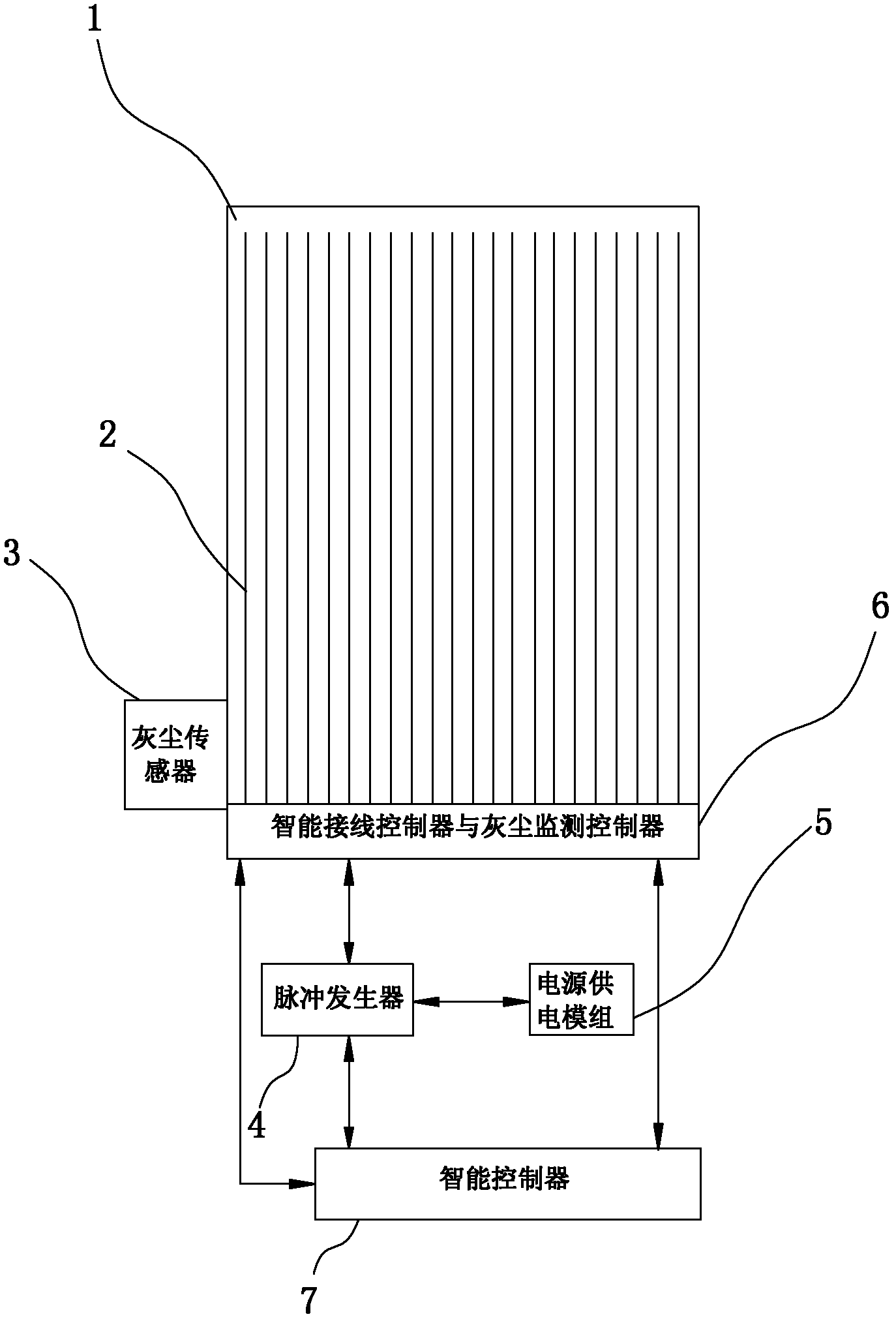

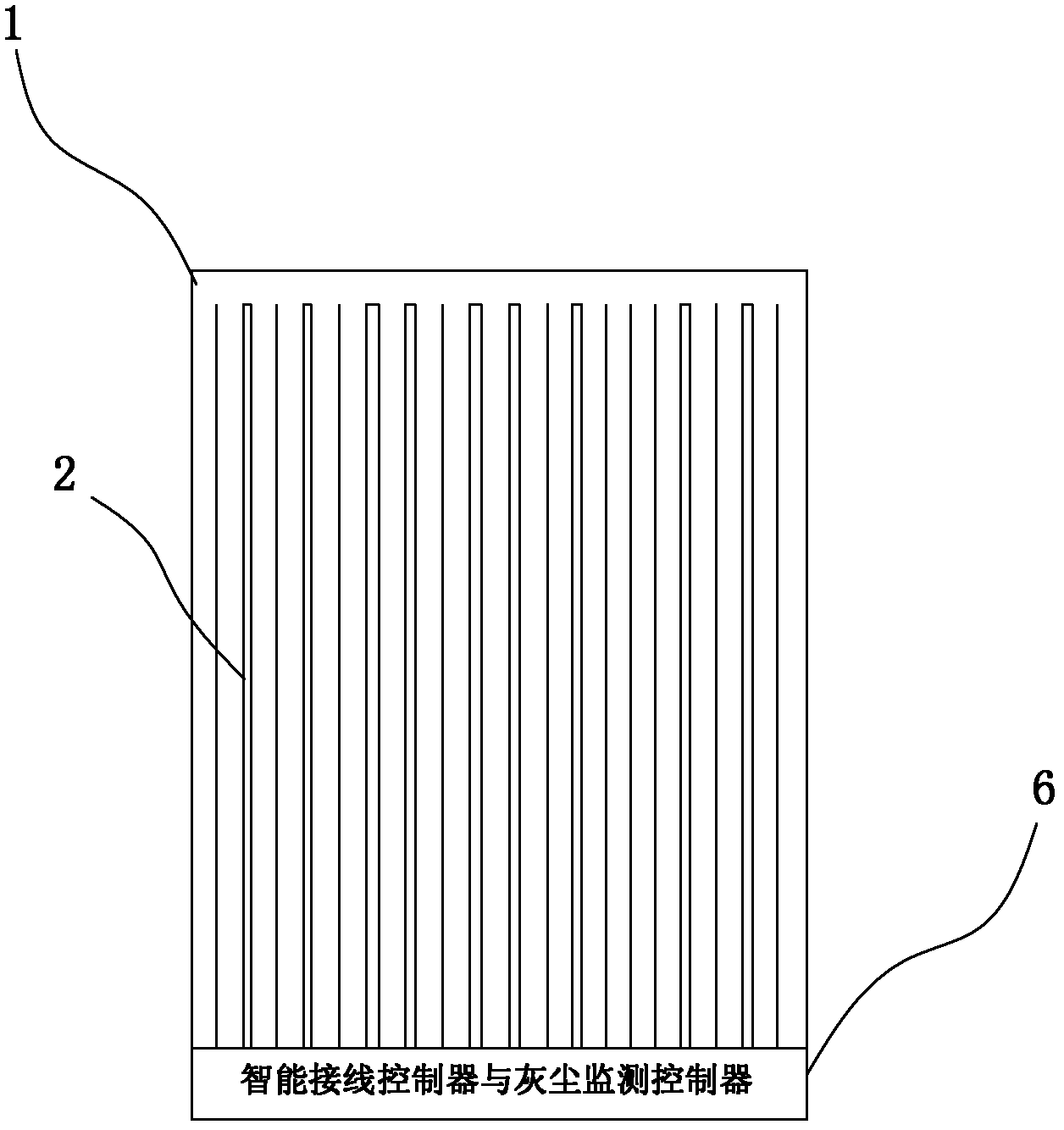

[0021] see Figure 1-2 In the first embodiment shown, the figure schematically reflects the installation and application structure diagram of a dust removal device implemented according to the present invention, and shows the basic principle of the present invention. The electrode 2 shown in the figure can be directly etched on the surface of the glass 1, or attached to the upper surface of the glass 1 by various known methods such as electroplating and film sticking.

[0022] Taking a solar cell panel as an example, the electrode 2 attached to the surface of the solar cell panel itself can use a white light projection material, which will not have adverse effects on the projection and absorption of light; the electrode 2 can use a selective transmittance material to ensure that the solar cell power generation efficiency.

[0023] figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com