Dust control unit used after assembling of mainframe box of computer

A technology of dust removal device and main box, applied in the direction of dust removal, chemical instruments and methods, digital processing power distribution, etc., can solve the problems of low dust removal efficiency, high labor intensity, poor dust removal effect, etc., to prevent dust from dispersing, protect health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

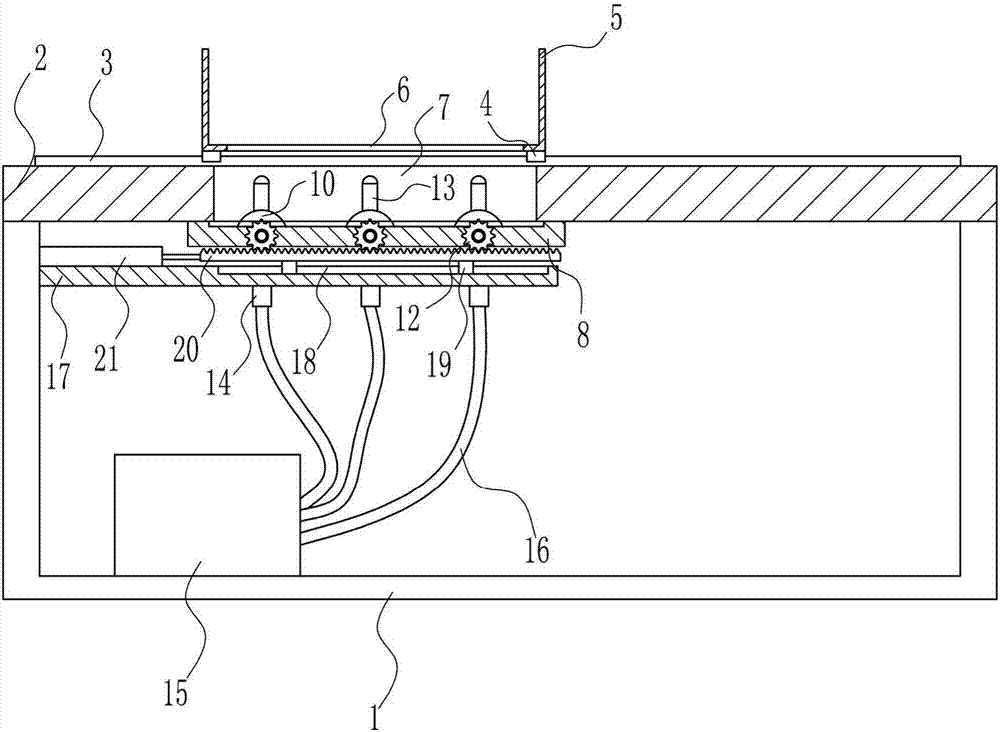

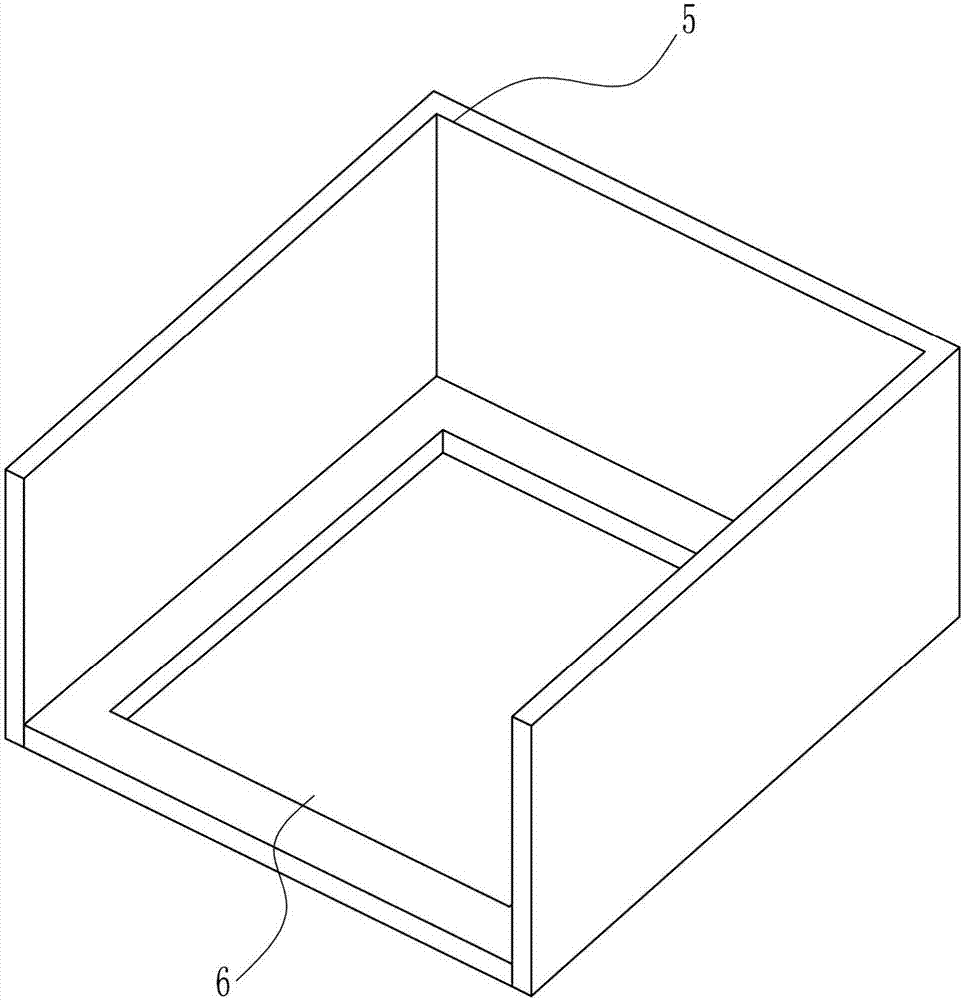

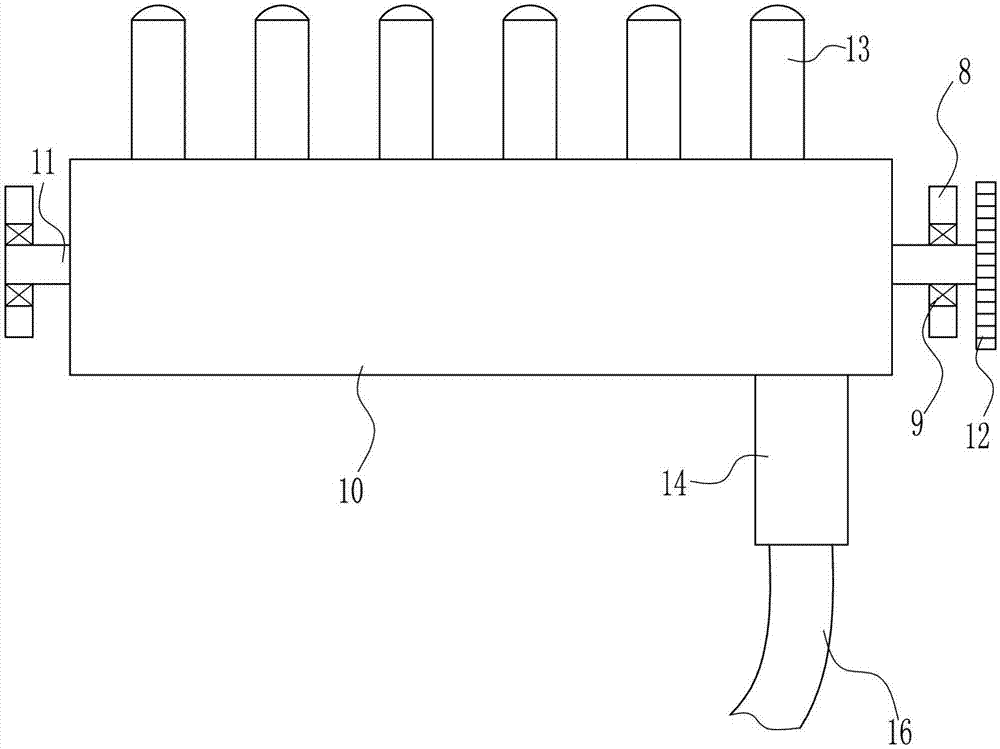

[0038] A dust removal device after assembly of a main computer case, such as Figure 1-8 As shown, it includes a first bracket 1, a workbench 2, a first slide rail 3, a first slider 4, a placement frame 5, a support plate 8, a first bearing seat 9, a main air pipe 10, a rotating shaft 11, a gear 12, Air spray head 13, joint 14, air pump 15, air injection pipe 16, horizontal plate 17, second slider 19, rack 20 and first cylinder 21, the top of the first support 1 is provided with a workbench 2, and the top of the workbench 2 passes through The way of bolt connection is horizontally connected with the first slide rail 3, and the first slide rail 3 is provided with two first slide blocks 4 matched with it, the first slide block 4 is slidingly matched with the first slide rail 3, and the two first slide rails The slide block 4 is left-right symmetrical, and the tops of the two first slide blocks 4 are connected with a placement frame 5 by means of bolt connection, the bottom of th...

Embodiment 2

[0040] A dust removal device after assembly of a main computer case, such as Figure 1-8 As shown, it includes a first bracket 1, a workbench 2, a first slide rail 3, a first slider 4, a placement frame 5, a support plate 8, a first bearing seat 9, a main air pipe 10, a rotating shaft 11, a gear 12, Air spray head 13, joint 14, air pump 15, air injection pipe 16, horizontal plate 17, second slider 19, rack 20 and first cylinder 21, the top of the first support 1 is provided with a workbench 2, and the top of the workbench 2 passes through The way of bolt connection is horizontally connected with the first slide rail 3, and the first slide rail 3 is provided with two first slide blocks 4 matched with it, the first slide block 4 is slidingly matched with the first slide rail 3, and the two first slide rails The slide block 4 is left-right symmetrical, and the tops of the two first slide blocks 4 are connected with a placement frame 5 by means of bolt connection, the bottom of th...

Embodiment 3

[0043] A dust removal device after assembly of a main computer case, such as Figure 1-8 As shown, it includes a first bracket 1, a workbench 2, a first slide rail 3, a first slider 4, a placement frame 5, a support plate 8, a first bearing seat 9, a main air pipe 10, a rotating shaft 11, a gear 12, Air spray head 13, joint 14, air pump 15, air injection pipe 16, horizontal plate 17, second slider 19, rack 20 and first cylinder 21, the top of the first support 1 is provided with a workbench 2, and the top of the workbench 2 passes through The way of bolt connection is horizontally connected with the first slide rail 3, and the first slide rail 3 is provided with two first slide blocks 4 matched with it, the first slide block 4 is slidingly matched with the first slide rail 3, and the two first slide rails The slide block 4 is left-right symmetrical, and the tops of the two first slide blocks 4 are connected with a placement frame 5 by means of bolt connection, the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com