Method for casting high-strength aluminum alloy round ingot by continuous oil gas lubrication

An oil-air lubrication and aluminum alloy technology, which is applied in the field of continuous oil-air lubrication casting of high-strength aluminum alloy round ingots, can solve problems such as the surface quality of high-strength aluminum alloy ingots that are prone to cracking, and achieve the effect of excellent surface quality and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

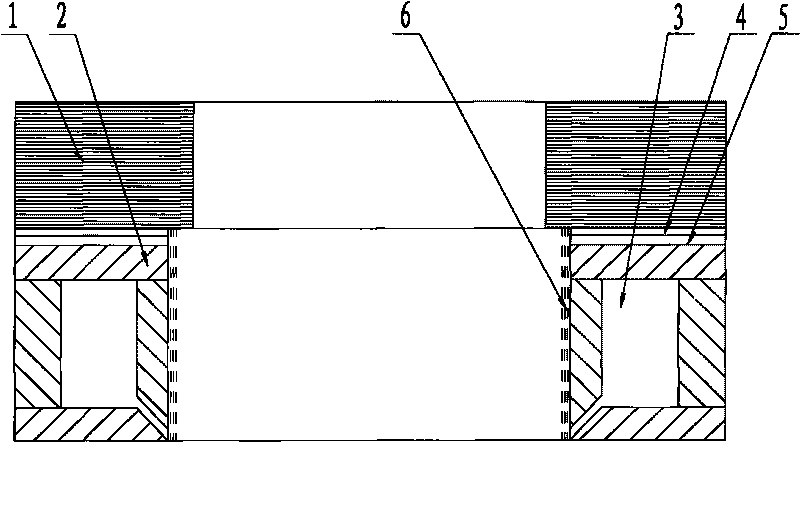

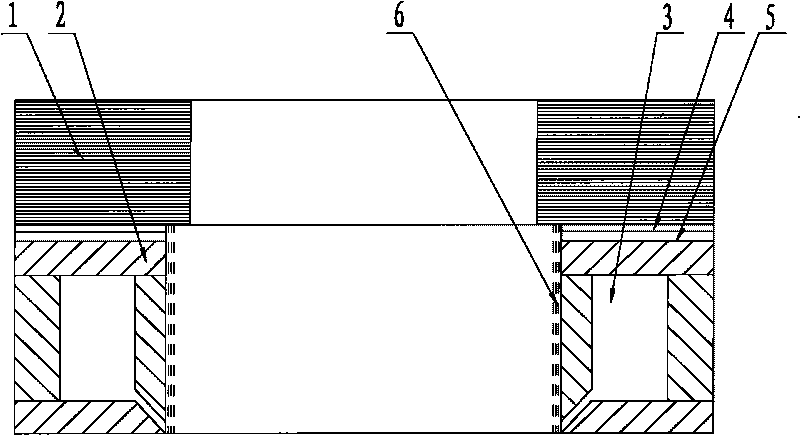

Image

Examples

Embodiment Construction

[0019] The continuous oil-gas lubricated casting process of high-strength aluminum alloy round ingots is as follows: first alloying and melting: put industrial pure aluminum ingots in an induction furnace for melting, and after melting, control the melt temperature within the range of 700-730°C and add industrial pure aluminum For zinc and industrial pure magnesium ingots, stir the melt and raise its temperature to 710-750°C, add Al-50Cu, Al-10Zr, Al-10Mn, Al-5Cr intermediate alloy ingots to the melt respectively, after stirring The melt is transferred to the resistance heating and heat preservation static furnace, and the temperature is raised to stand still; then the melt is treated: the temperature of the melt is kept at 720-750°C, and the melt is refined and slag-broken by using a sodium-free refining agent and a slag-breaking agent. Remove the oxidized slag on the surface of the melt and let it stand for 10 to 20 minutes; add Al-5Ti-B wire rod to the heat preservation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com