Ball high-speed motorized spindle

A high-speed motorized spindle and ball technology, used in large fixed members, maintenance and safety accessories, drive devices, etc., can solve the problems of short service life, limited effect, and poor sealing effect of the sealing rubber ring, so as to improve the running accuracy, improve the Lubrication effect, effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

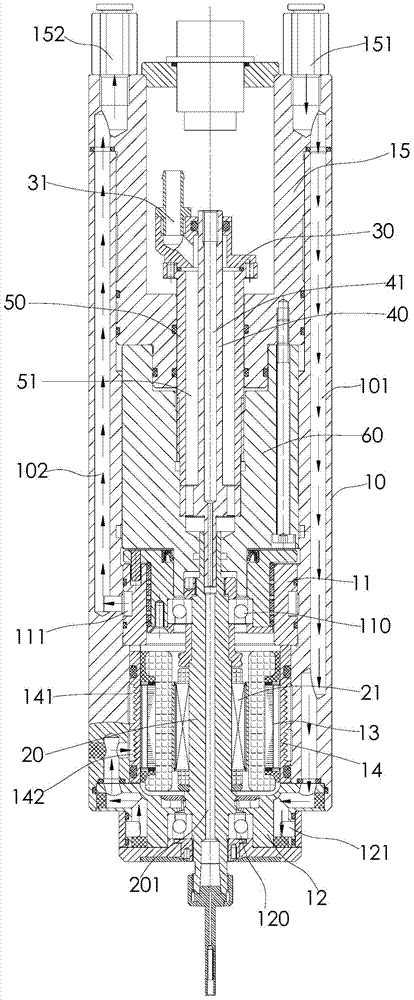

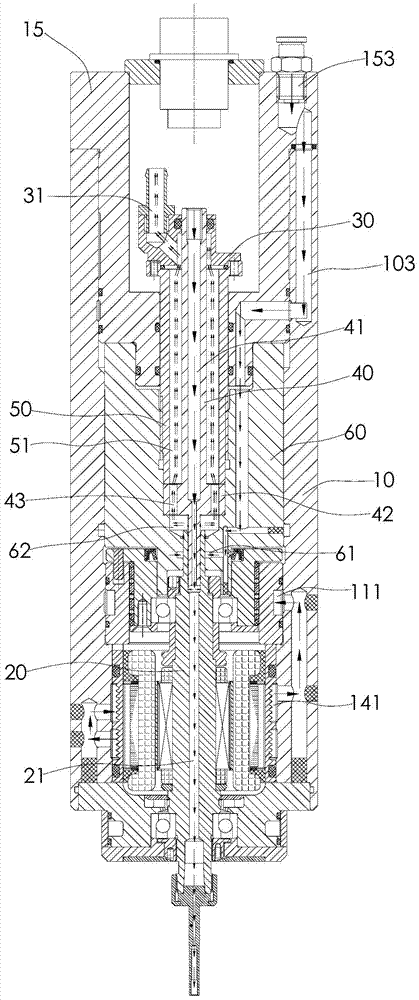

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

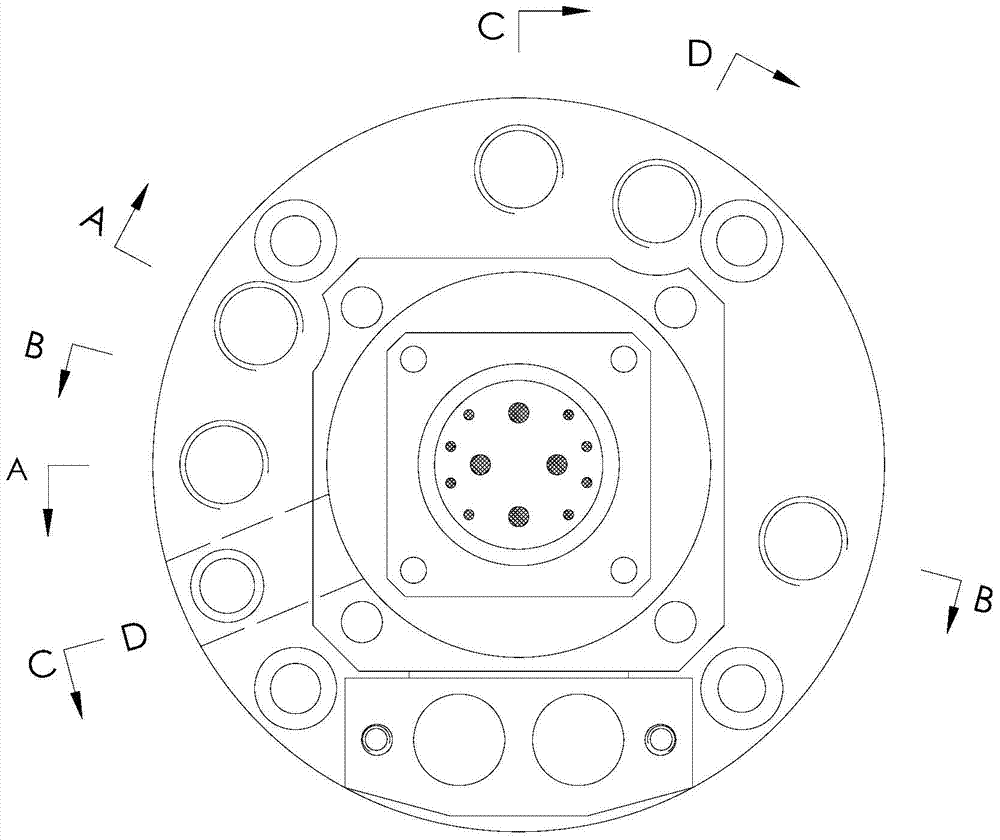

[0037] see figure 1 , 2 , 3, 4, 5, the ball high-speed electric spindle of the present invention includes a body assembly and a shaft core assembly, wherein the body assembly includes a body 10, an upper bearing seat 11, a lower bearing seat 12, a stator 13, and a heat conduction sleeve 14, wherein, Both the body 10 and the heat conduction sleeve 14 are in a cylindrical shape, the heat conduction sleeve 14 is fixed inside the body 10, and its outer surface is tightly bonded to the inner surface of the body 10, the stator 13 is fixed inside the heat conduction sleeve 14, the upper bearing seat 11 and the lower The bearing blocks 12 are all fixedly connected with the machine body 10 .

[0038] The outer surface of the heat conduction sleeve 14 is provided with a first annular cooling groove 141 and a second annular cooling groove 142 surrounding the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com