Bearing for air refrigerating machine driven by high-speed motor and the air refrigerating machine

An air refrigerator, high-speed motor technology, applied in the field of bearings, can solve the problems of low reliability, short service life, high price, etc., and achieve the effect of stable and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

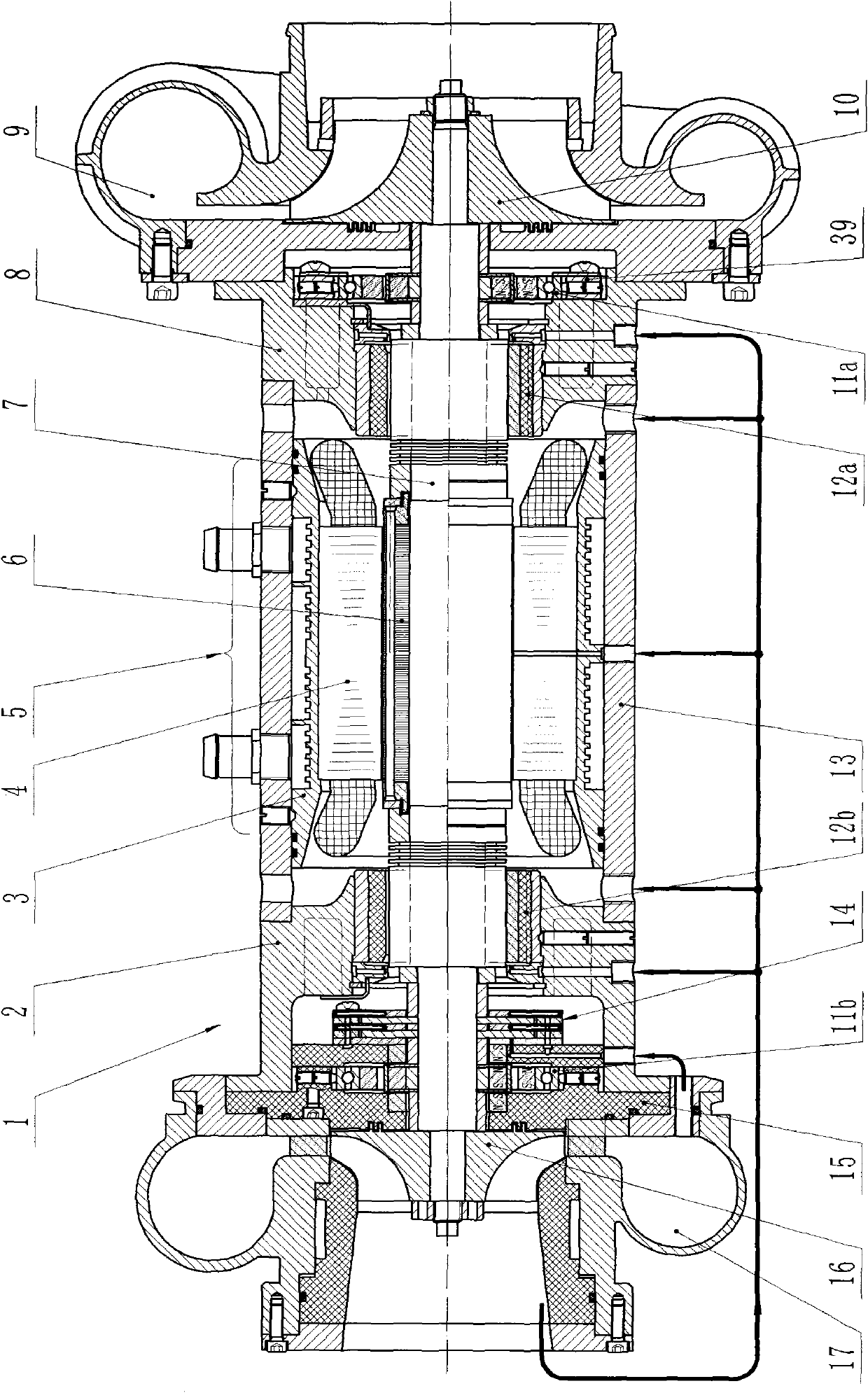

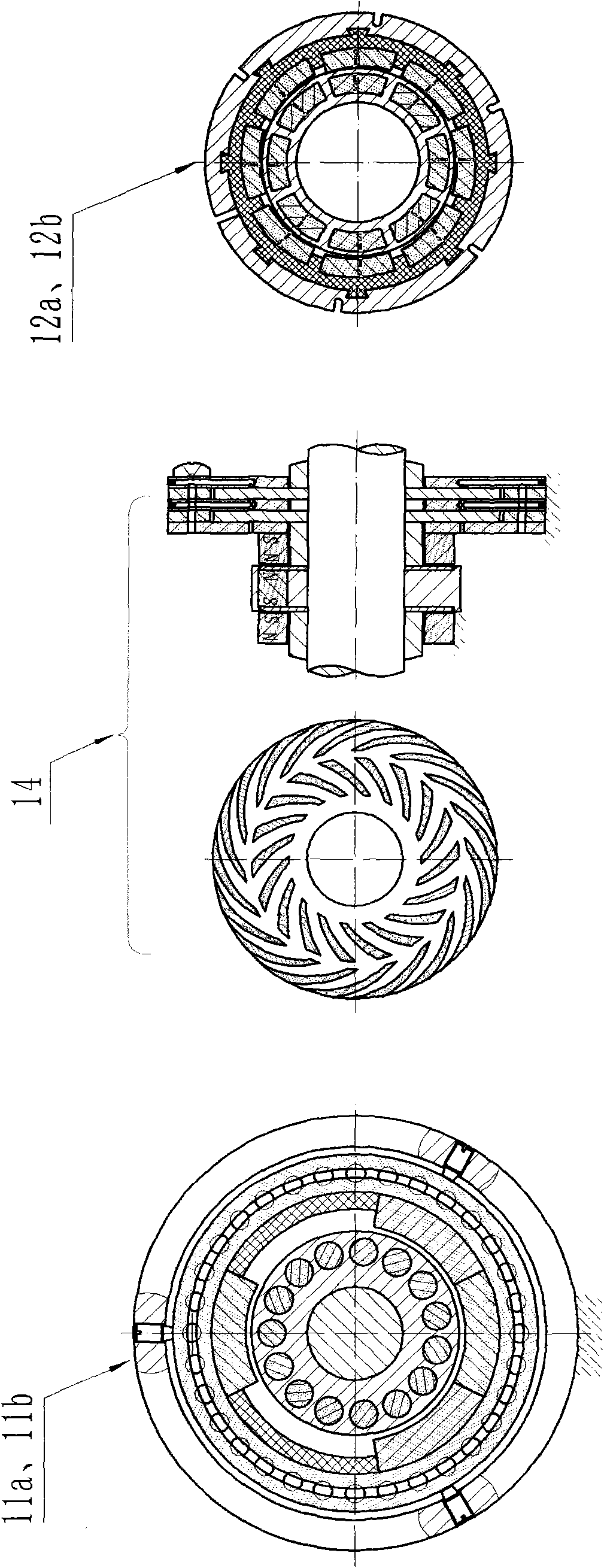

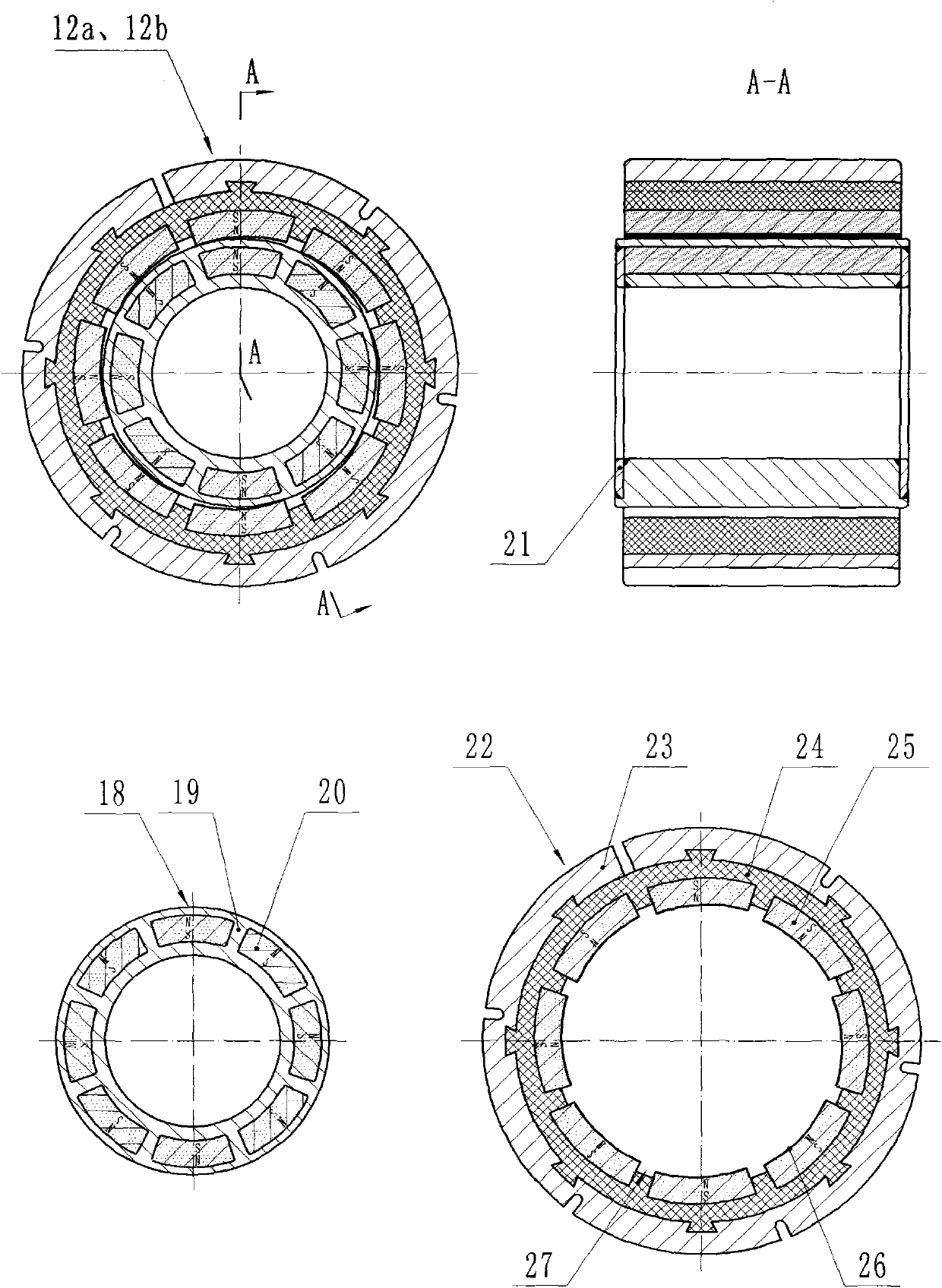

[0011] The specific embodiments of the present invention will be described below in conjunction with the drawings. figure 1 Shown as a front view of an air refrigerator 1 driven by a high-speed motor. The refrigerator 1 is composed of two elastically supported permanent magnet and air dynamic pressure hybrid radial bearings 12a and 12b, a permanent magnet and The aerodynamic and static pressure hybrid thrust bearing group 14 and the electric motor 5 supported by the two permanent magnet radial unloading auxiliary bearings 11a and 11b are directly driven. The air refrigerator 1 includes an electric motor 5 in its middle. The electric motor 5 includes a rotor 6 and a stator 4.

[0012] figure 1 Among them, two radial bearings 12a and 12b are respectively installed on the rotor shaft 7 between the center of the left bearing housing 2 and the right bearing housing 8 of the housing 13 and the housing 13, and the left bearing housing 2 is connected to the turbine 17, The right bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com