Intelligent oil-gas lubrication monitoring system and method

An intelligent monitoring system, oil-air lubrication technology, applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve problems such as inability to judge schlieren signals, oil film can not reach the lubrication effect, and cannot meet the needs of working conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

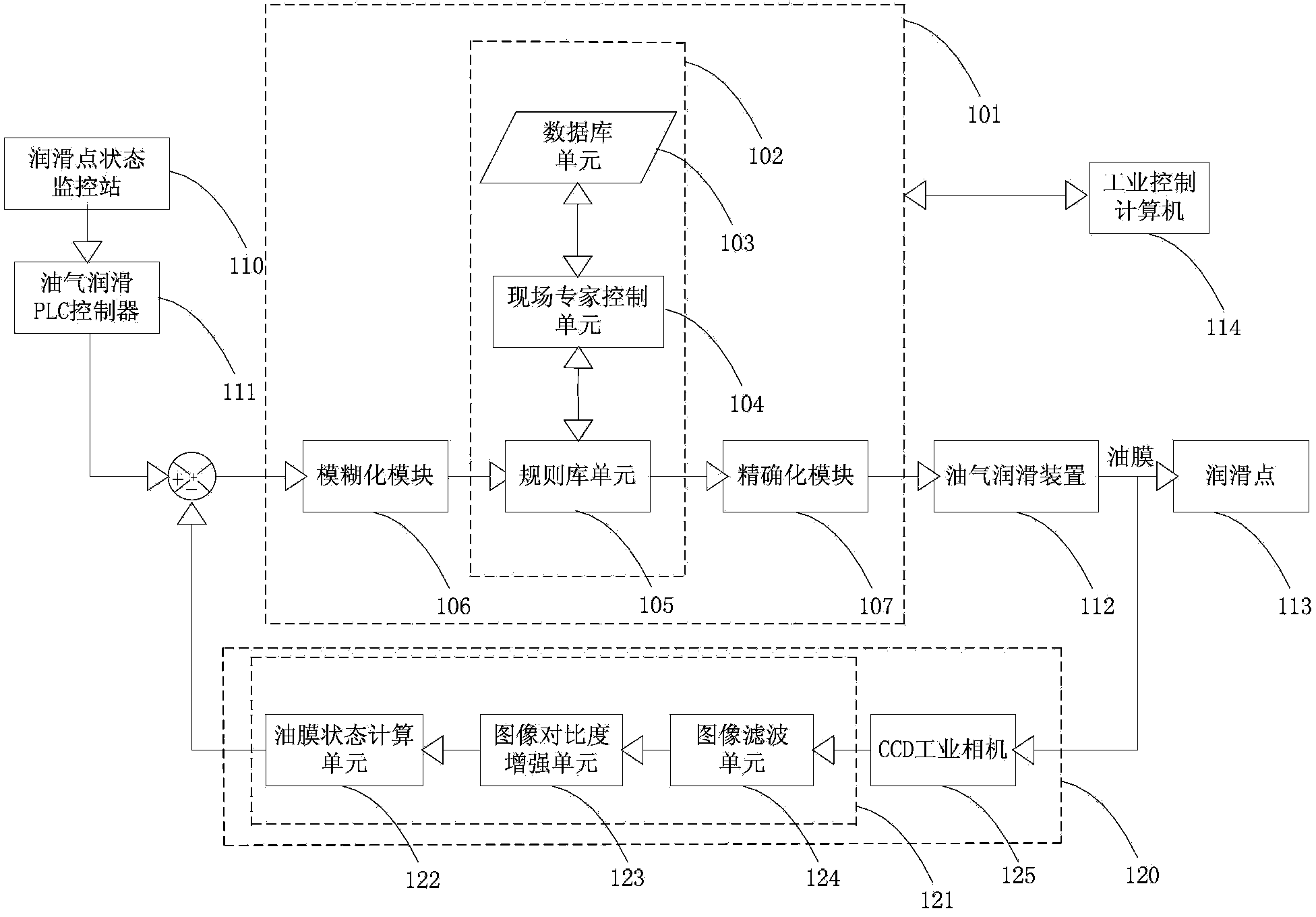

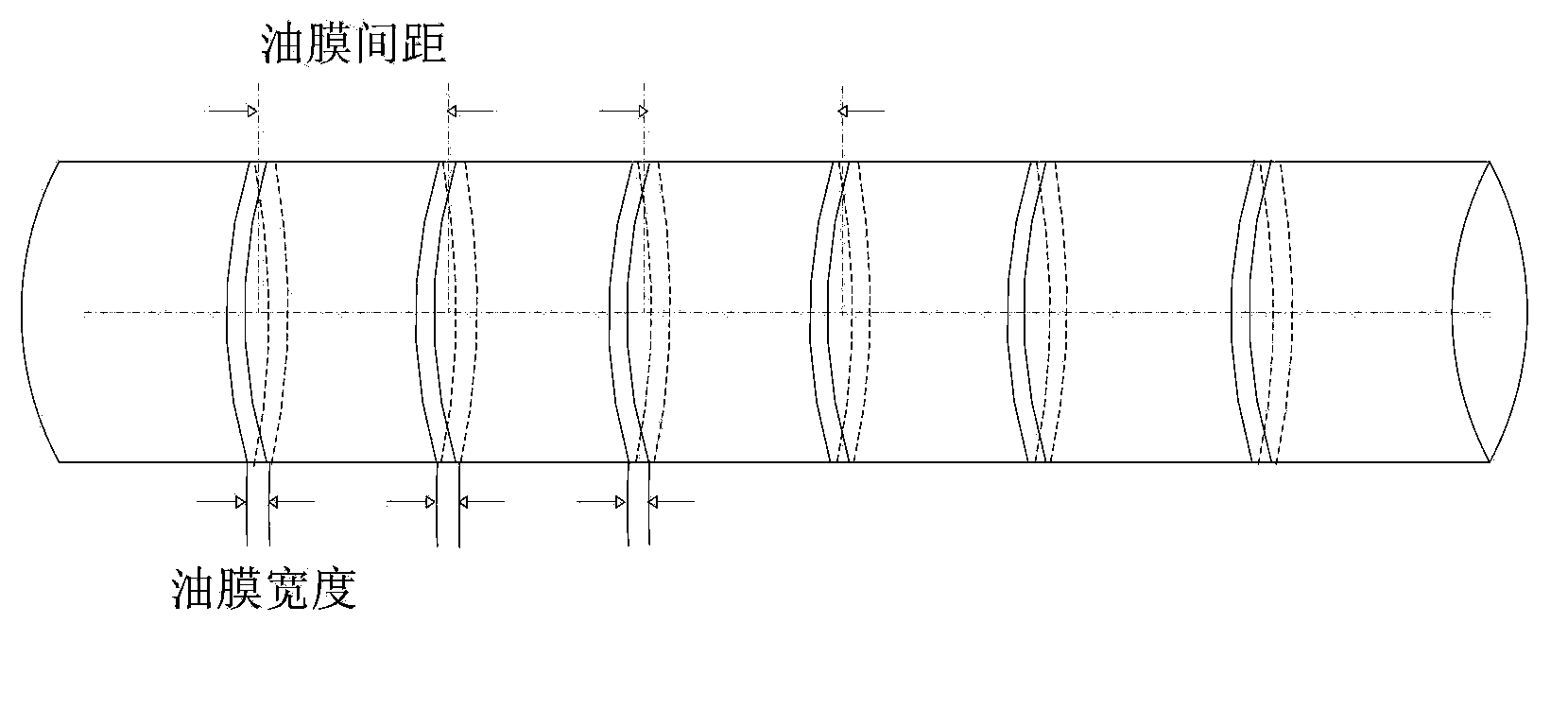

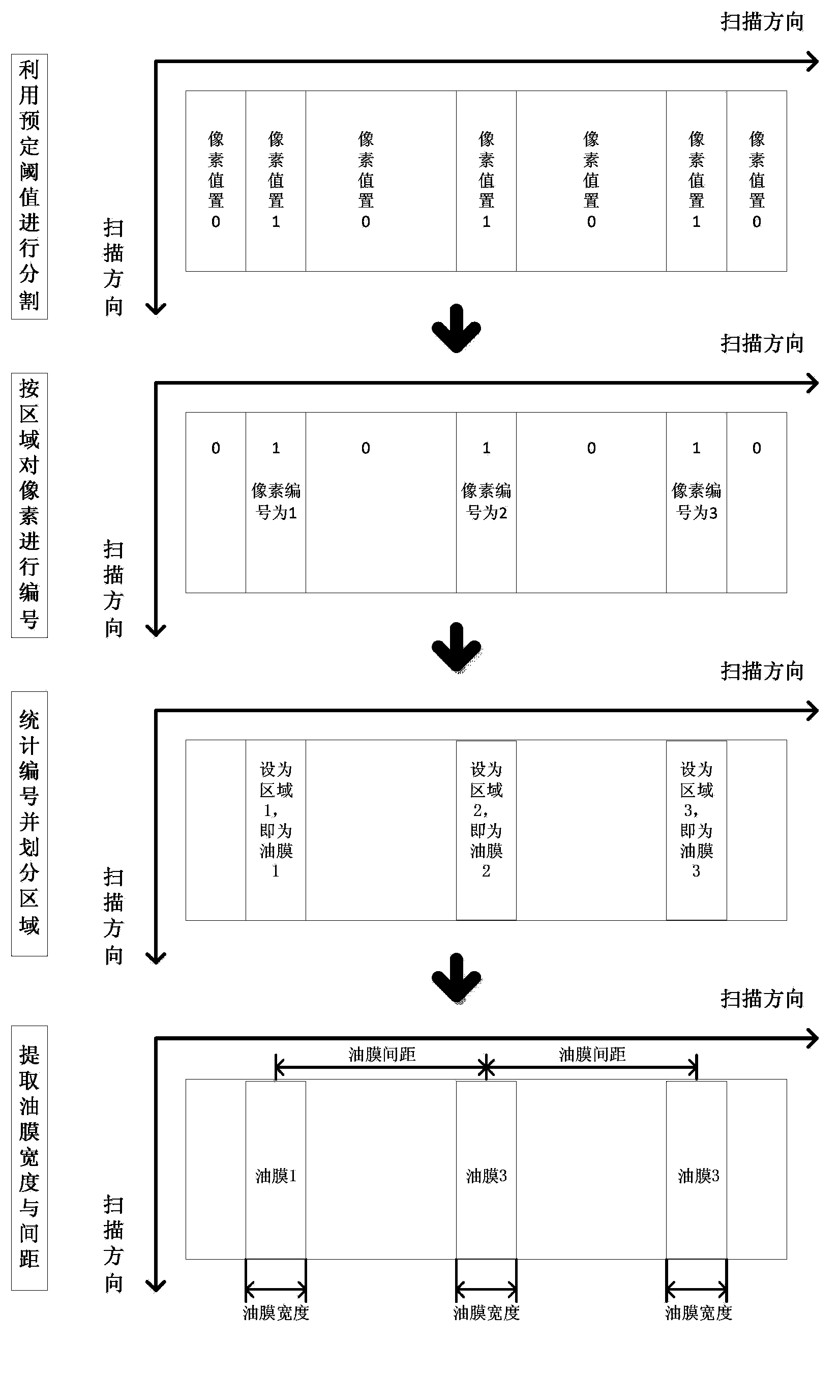

[0063] Such as figure 1 As shown, the oil-air lubrication intelligent monitoring system of the present invention includes a lubrication point status monitoring station 110, an oil-air lubrication PLC (programmable logic) controller 111, an industrial control computer 114, an oil-air lubrication device 112, an intelligent visual sensor 120, and a fuzzy controller 101 , the intelligent vision sensor 120 is vertically arranged above the transparent delivery pipeline of the oil-air lubrication device 112, the intelligent vision sensor 120 collects and processes the oil film image attached to the inner wall of the transparent delivery pipeline of the oil-air lubrication device 112, and calculates the oil film state data according to the oil film image, The oil film state data includes oil film width, oil film distance, and oil film quantity; and the oil film image and oil film state data are transmitted to the visual man-machine operation interface of the industrial control computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com