Static pressure air floatation thrust bearing based on multi-ring belt exhaust

A technology of thrust bearings and air bearings, applied in the direction of static pressure bearings, air cushion bearings, bearings, etc., can solve the problems of affecting bearing performance, uncontrollable outlet pressure, difficult to balance load bearing and stability, etc., and achieve good adaptability , taking into account the effect of load bearing and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

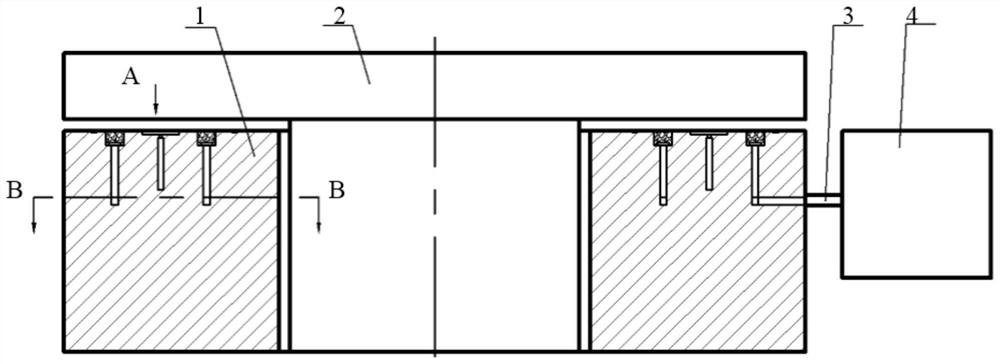

[0031] refer to figure 1 , the multi-ring exhaust type composite static pressure gas thrust bearing of the present invention includes an air bearing sleeve 1, an air bearing shaft 2, an air guide tube 3 and a flow control device 4.

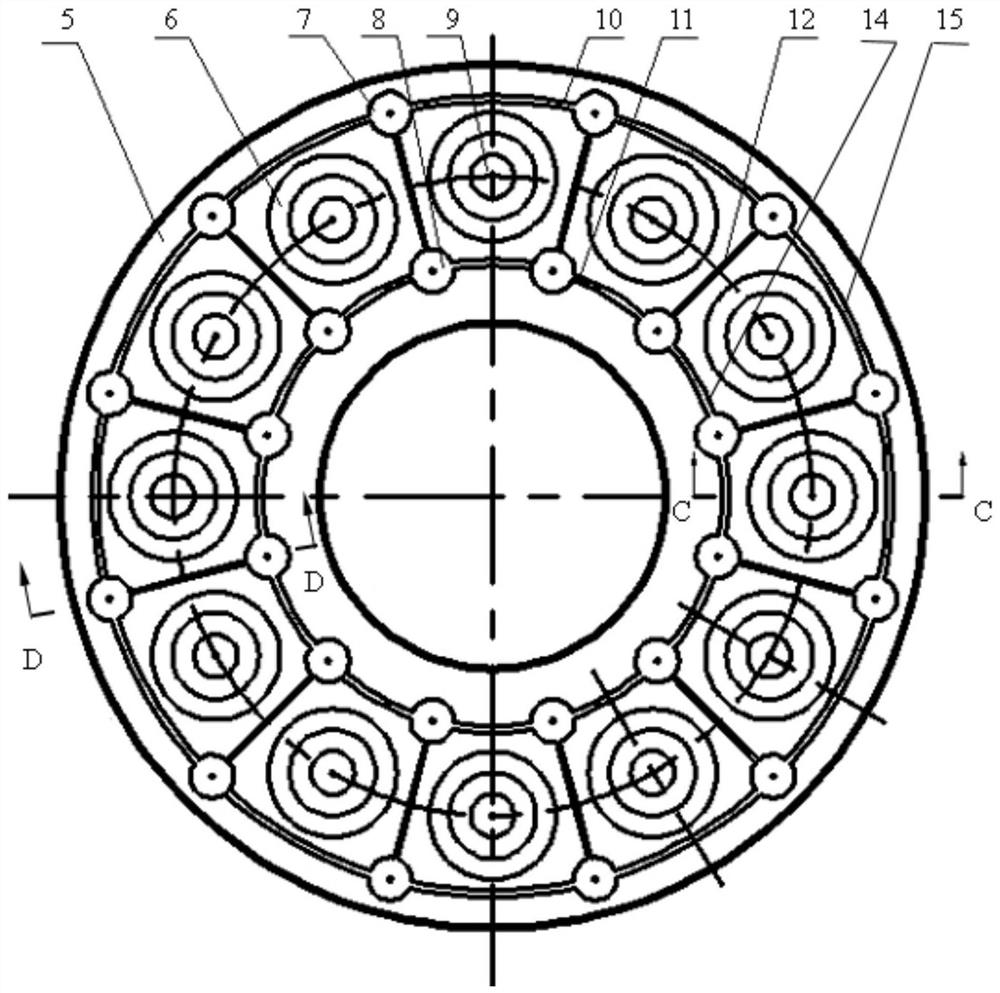

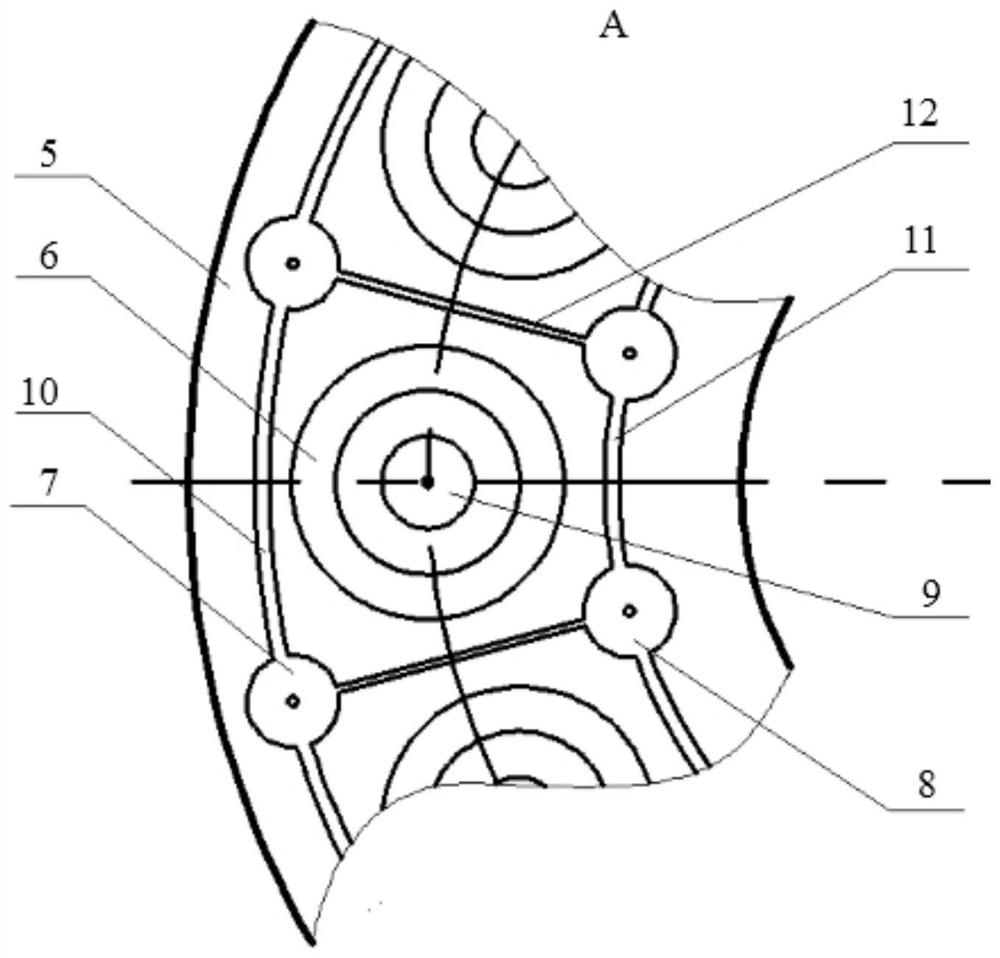

[0032] refer to figure 2 The air bearing cover 1 includes a base 5 and a porous ring 6, the porous ring 6 is evenly inlaid on the ring-shaped base 5 along the circumference, and the outer ring nodes are evenly distributed along the circumference of the base. flow restrictor, pressure control restrictor and inner ring restrictor, and the distribution circle radii of the outer ring restrictor, pressure control restrictor and inner ring restrictor decrease in turn, the pressure restrictor and multi-hole The number of mass ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com