Oil-gas lubrication pipeline in main shaft structure

A technology of oil-air lubrication and oil inlet pipelines, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. It can solve problems such as inability to lubricate bearings, high heat generated by bearings, and affect the accuracy of the spindle, so as to improve heat dissipation efficiency , good heat dissipation, effective cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

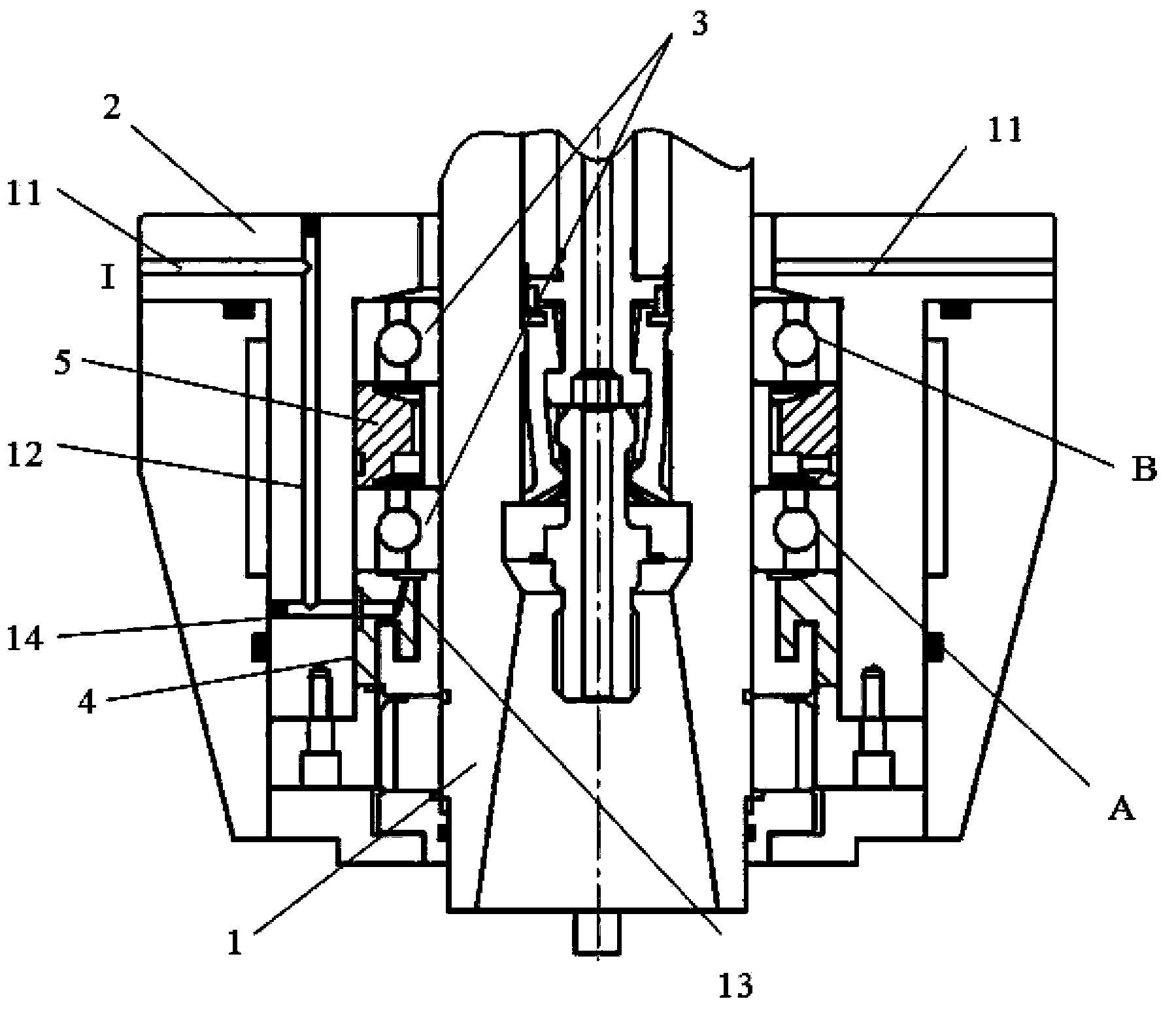

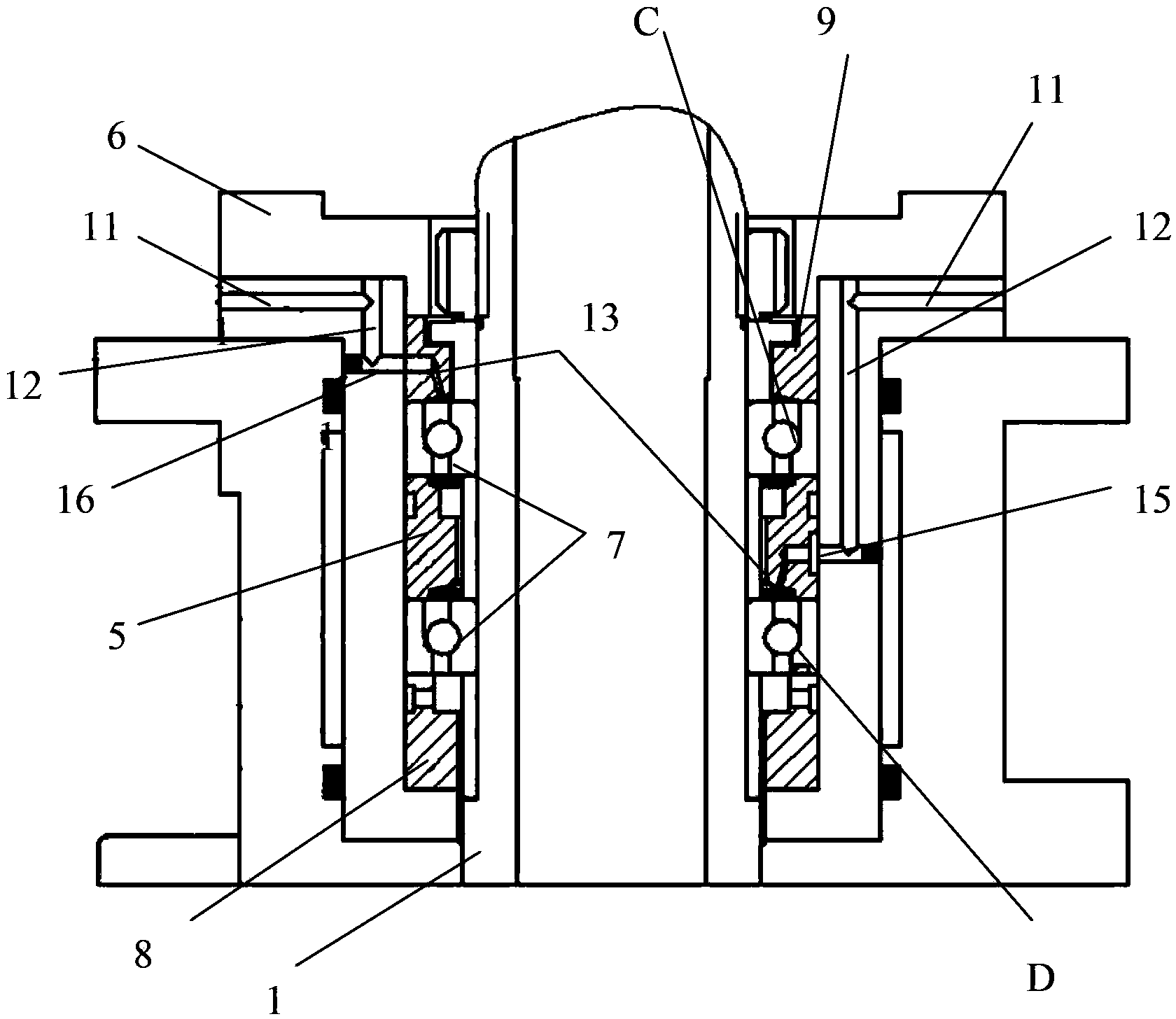

[0023] Traditional lubrication methods are not suitable for the lubrication requirements of high-speed spindles, while oil-air lubrication is more suitable for the lubricating oil volume and viscosity of high-speed spindle bearings. At present, the oil-air lubrication pipeline of the electric spindle bearing of the traditional high-speed vertical machining center is a single-group lubrication method, which cannot effectively lubricate the bearing, and the heat generated by the bearing is large, and the heat generated cannot be effectively dissipated through lubrication. Affects spindle accuracy.

[0024] The present invention aims at the deficiencies in the prior art. The present invention provides an oil-air lubrication pipeline with a main shaft structure to adapt to the application of the main shaft high-speed five-axis precision vertical machining center, so that the bearing is always in the best lubrication state, and at the same time can Form a lubricating oil film with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com