Tester for soil vertical and radial expansive deformation and expansive force relation

A technology of deformation testing and radial expansion, which is applied in soil testing, instruments, measuring devices, etc., can solve the problems of inaccuracy, long data processing time period, and the inability to consider the measurement of expansion force and expansion volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

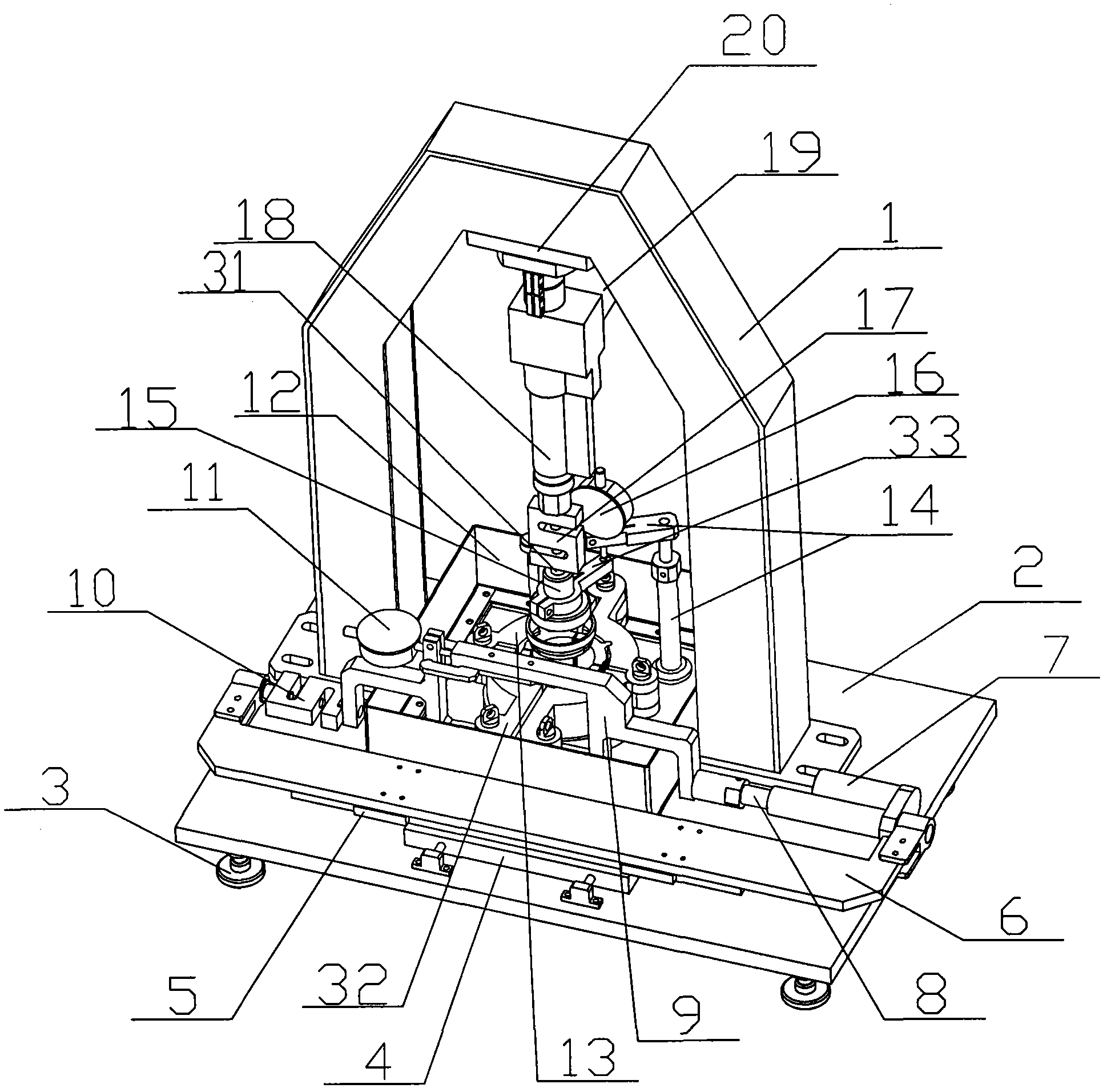

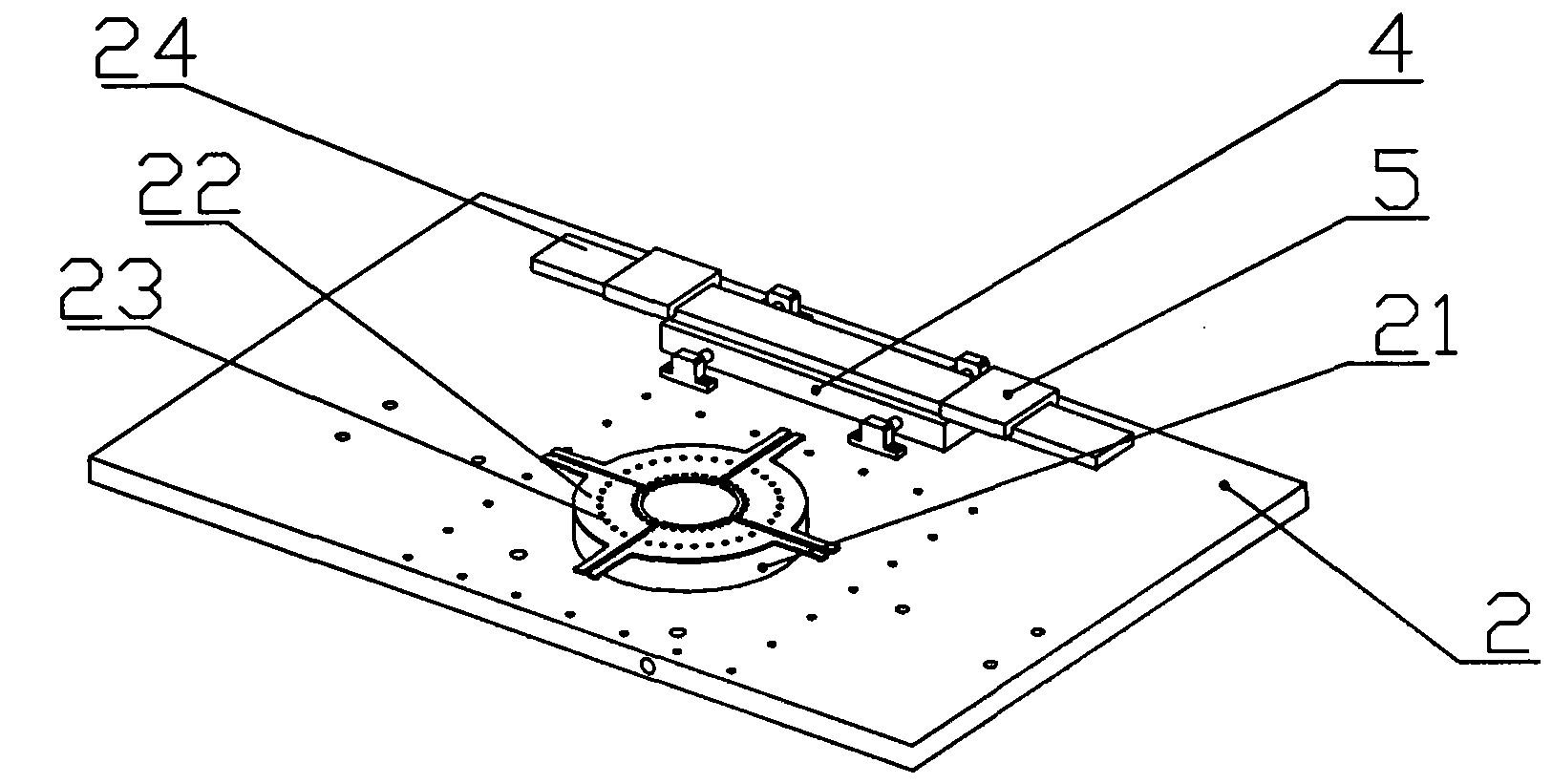

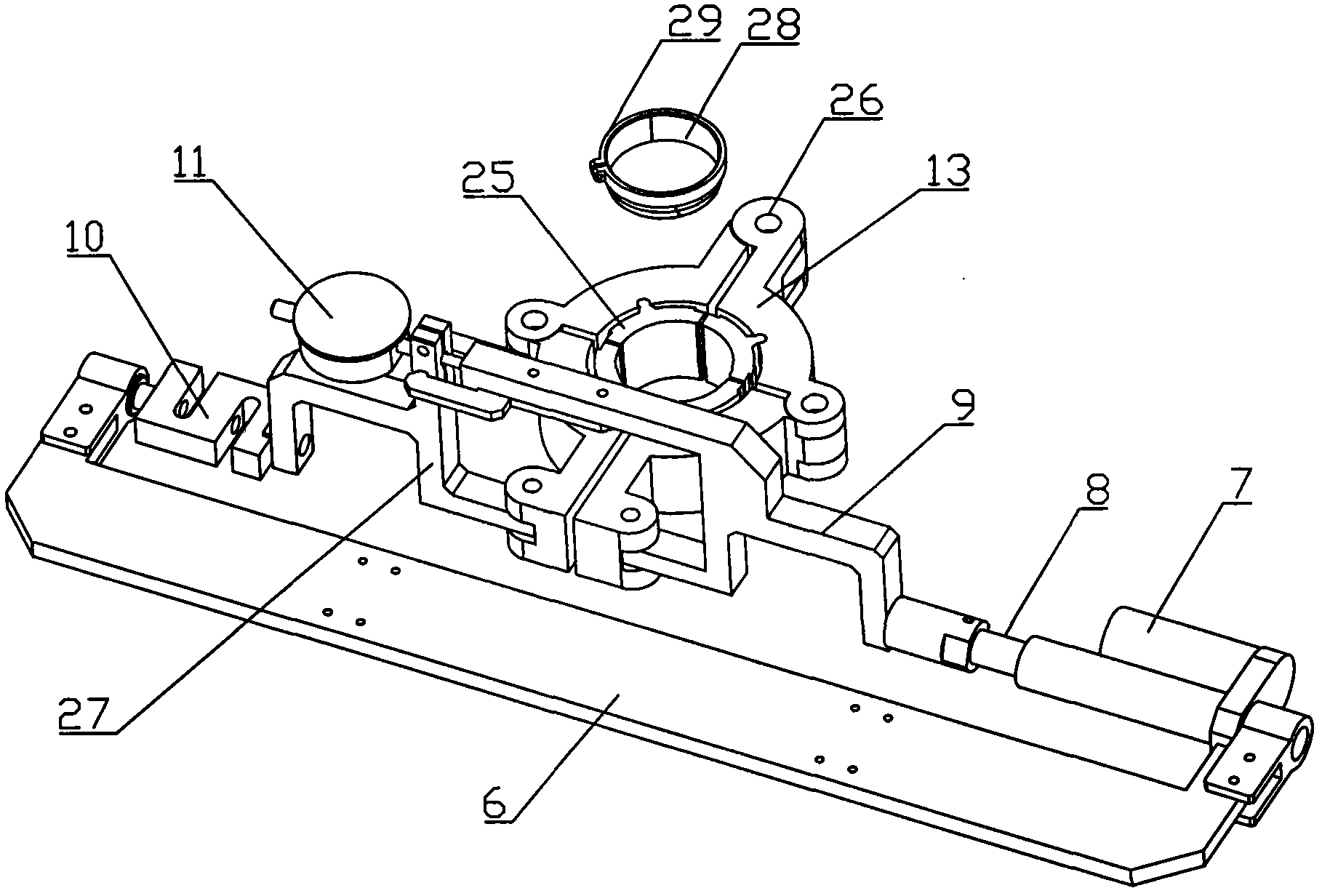

[0024] The invention provides a tester for testing soil vertical and radial expansion force and expansion deformation, the tester includes a friction reducing device ( figure 2 ), sample retaining ring parts ( image 3 ), confining pressure and radial deformation test parts ( image 3 ), vertical pressure and deformation test parts, data acquisition instrument; the friction reducing device is located in the immersion tank, and the sample retaining ring part is placed on the friction reducing device in the center of the immersion tank, through the extension of the confining pressure outer ring block assembly 13 The rod 32 is connected with the confining pressure and radial deformation test components; the data acquisition instrument is located outside and connected with each sensor through the data line; the data acquisition instrument is connected with the computer through the data line.

[0025] The friction reducing device, also known as the "floating" device, can effectiv...

Embodiment 2

[0044] Embodiment 2 This instrument usage method:

[0045] 1. Preparation of soil samples

[0046] The soil sample was passed through a 2mm sieve, mixed with soil according to the predetermined moisture content, mixed evenly, and stuffed with a plastic bag for a day and night.

[0047] Tighten the special test ring blade 28 (four small petals together) with No. 1 ring hoop 29, screw on the small bolt 30 of the ring hoop, apply Vaseline inside and weigh the mass m 0 .

[0048] Put the assembled test ring blade 28 into the static pressing sample cylinder, weigh a certain amount of prepared soil sample, add the same amount into the cylinder in three equal amounts, use a knife to gently insert it and smooth the surface, and gently vibrate the test cylinder A few strokes to make the soil sample slightly compact. Smooth the compaction cylinder, go to the base of the CBR compaction instrument, adjust the CBR pointer to zero, and electrically adjust the CBR knob (down first, then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com