Control method for controlling normal start and stop of push rod of test board of close-fitting checker

A technology of close-fitting checker and start-stop control, applied in the direction of instruments, measuring devices, etc., can solve the problem of not supporting user-defined strokes, etc., and achieve the effect of meeting the test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

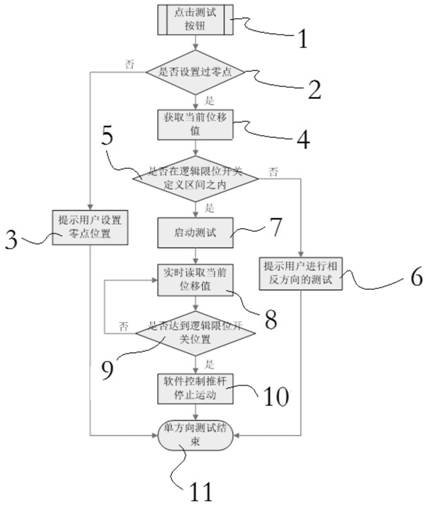

Method used

Image

Examples

Embodiment 1

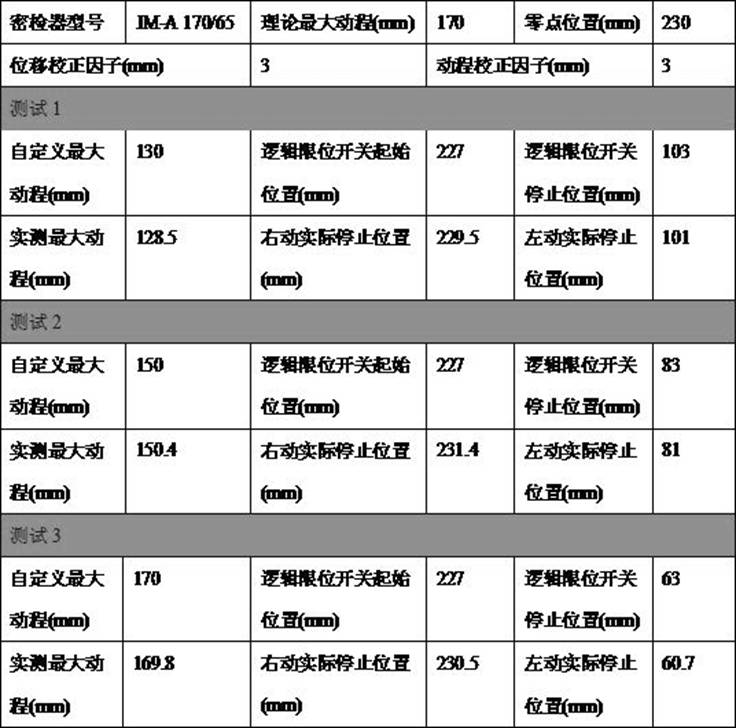

[0076] Citing the following specific data, and substituting the data into the steps and formulas, explain the effect of the following adhesion checker model JM-A170 / 65:

[0077]

example 1

[0078] In Example 1, for the JM-A 170 / 65 model, three tests were carried out, and the user-defined maximum strokes were: 130mm, 150mm and 170mm. Through the control of the logic limit switch, the measured actual maximum strokes are respectively: 128.5mm, 150.4mm and 169.8mm.

Embodiment 2

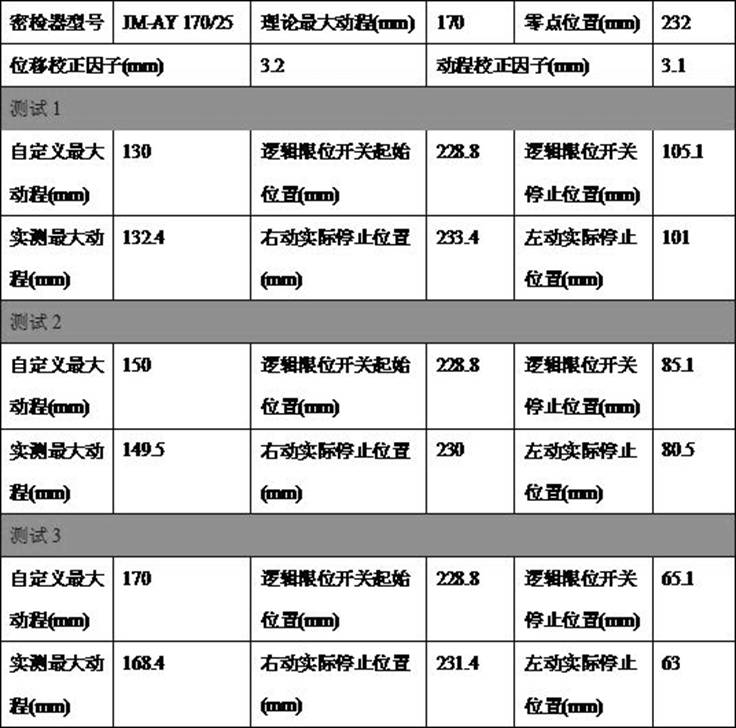

[0080] Citing the following specific data, and substituting the data into the steps and formulas, explain the effect of the following adhesion checker model JM-AY170 / 25:

[0081]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com