High-moisture-absorption acrylic fiber containing quinoline copper and preparation method of high-moisture-absorption acrylic fiber

An acrylic fiber with high moisture absorption technology, which is applied in wet spinning, fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems that metal elements cannot be added, can only be used on the surface, and antibacterial components cannot be fully utilized. It is not easy to achieve Effect of drop, hygroscopicity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

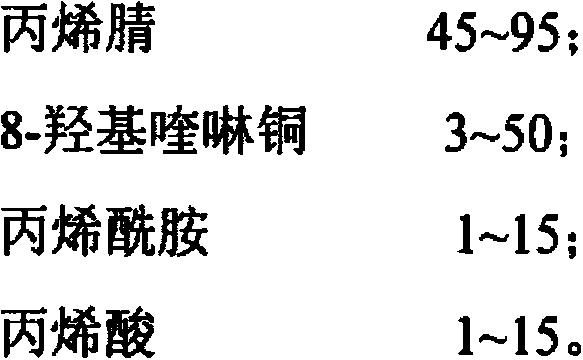

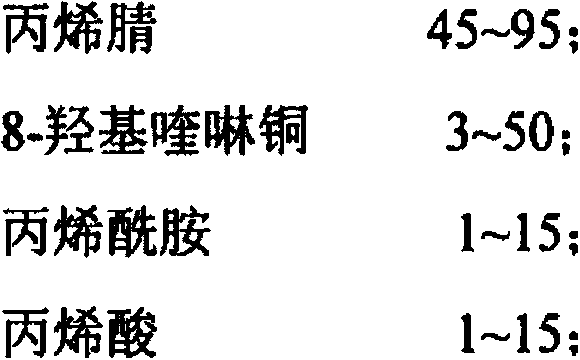

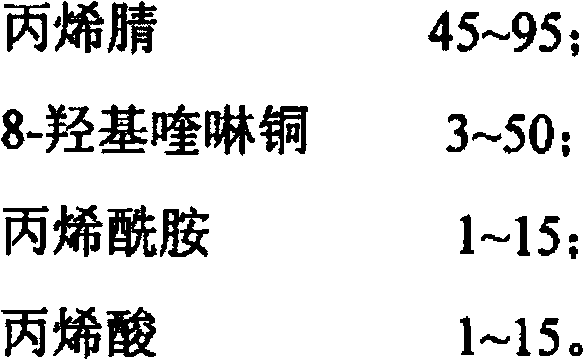

[0020] Put 75 grams of acrylonitrile monomer, 5 grams of 8-hydroxyquinoline copper, 5 grams of acrylamide and 5 grams of acrylic acid into 50 wt% zinc chloride salt solvent (pH<2) and stir evenly, heat up to 40 ° C and put The oxidant sodium persulfate and the reducing agent potassium sulfite, the reducing agent is 2.5 times that of the oxidizing agent, make it stand for 30 hours after reacting for 1 hour, wet spinning after 12 hours of defoaming, and enter the 15% concentration of zinc chloride salt solvent , solidified at 5°C, then pulled up in hot water at 100°C, washed in neutral hot water at 90°C, finally dried, shaped, cut and packaged to obtain copper-containing high-hygroscopic fibers.

Embodiment 2

[0022] Put 90 grams of acrylonitrile monomer, 5 grams of 8-hydroxyquinoline copper, 2.5 grams of acrylamide and 2.5 grams of acrylic acid into a 50 wt% zinc chloride salt solvent (pH<2) and stir evenly, heat up to 40°C and put in the oxidant Sodium persulfate and reducing agent potassium sulfite, the reducing agent is 1.5 times of the oxidizing agent, make it stand still for 30 hours after reacting for 1 hour, wet spinning after 12 hours of defoaming, enter in the zinc chloride salt solvent of 10% concentration, It is solidified at 5°C, then pulled up in hot water at 100°C, washed in neutral hot water at 90°C, finally dried, shaped, cut and packaged to obtain copper-containing high-hygroscopic fibers.

Embodiment 3

[0024] Put 50 grams of acrylonitrile monomer, 20 grams of 8-hydroxyquinoline copper, 15 grams of acrylamide and 15 grams of acrylic acid into 60 wt% zinc chloride salt solvent (pH < 2) and stir evenly, heat up to 40 ° C and put in the oxidant Sodium persulfate and reducing agent potassium sulfite, the reducing agent is 3 times that of the oxidizing agent, make it stand still for 30 hours after reacting for 1 hour, wet spinning after 12 hours of defoaming, enter in the zinc chloride salt solvent of 15% concentration, It is solidified at 5°C, then pulled up in hot water at 100°C, washed in neutral hot water at 90°C, finally dried, shaped, cut and packaged to obtain copper-containing high-hygroscopic fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com