Pants products packing device and method

A pants-type product, packaging machine technology, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problems of inability to achieve continuous and uninterrupted packaging, inability to increase compression speed, inability to package high costs, to avoid bursting of packaging bags, to achieve Fast cut-off and reliable heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

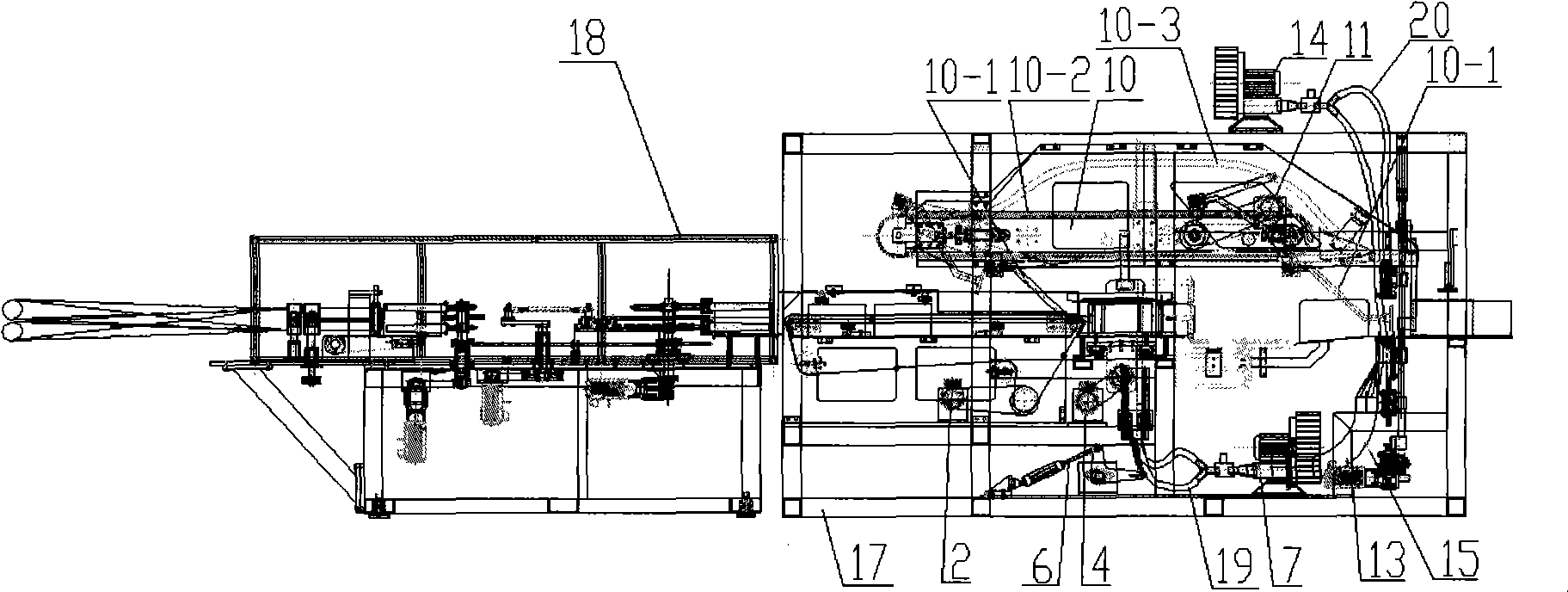

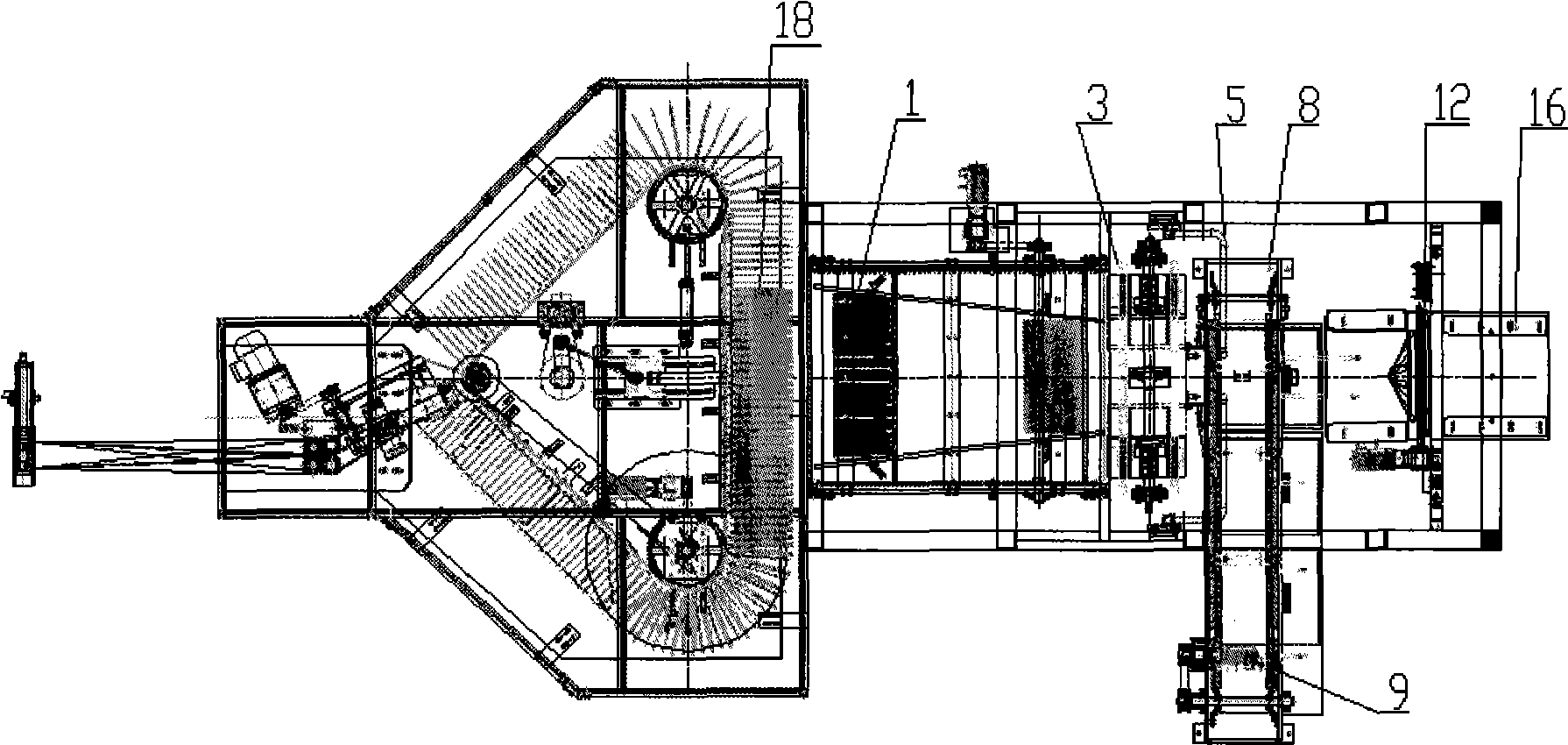

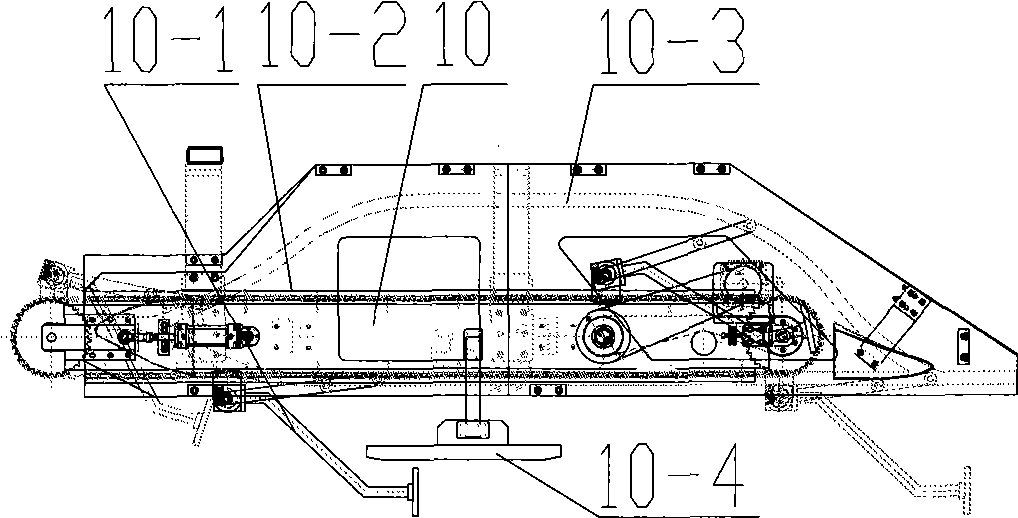

[0011] Embodiment 1: refer to Figure 1~3 . Pants-type product packaging machine, which includes a frame 17, a sealing and trimming device 12, and a waste recycling device 15. The moving pre-compression device is a shrinking channel 1, and two sets of mutually symmetrical ring chain transmissions are arranged on both sides of the shrinking channel 1. The mechanism 2 is driven by the pre-compression servo motor 2-3, and the distance between multiple push rods 2-1 is horizontally distributed between the two ring chains 2-2 in the two sets of ring chain transmission mechanisms 2, and the multiple push rods 2-1 are two The ends are respectively connected with two ring links 2-2 and rotate synchronously with the ring chain 2-2; the product compression device 3 is located at the exit of the contraction channel 1 and drives the double-headed screw through the compression servo motor 4, and the double-headed screw at both ends The direction of the screw thread is opposite and rotates...

Embodiment 2

[0012] Embodiment 2: On the basis of embodiment 1, the packaging method of the trousers type product packaging machine includes a PLC controller, and the stacker 18 pushes out the product to be packaged, enters the movable pre-compression device 1, and undergoes pre-compression After exhaust, the pre-compressed trousers products are pushed into the product compression device 3 by multiple push rods distributed in the endless chain transmission mechanism on both sides of the movable pre-compression device 1, and the product compression device 3 is driven by the drive motor 4. The two compression plates that drive the double-headed screw move quickly relative to each other to perform secondary compression on the trousers product. At this time, the product bag opening device 5 is under the instruction of the PLC controller, and its negative pressure suction nozzle 21 will compress the bag. At the same time as the bag mouth is sucked open, the double door located at the exit of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com