Headstock pipe positioning device of motorcycle frame welding tool

A positioning device and welder's technology, applied in the field of tooling fixtures, can solve the problems of not being able to catch up with the launch of the product, high product cost, long preparation time, etc., and achieve the effect of convenient disassembly, flexibility, good versatility, and complete interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

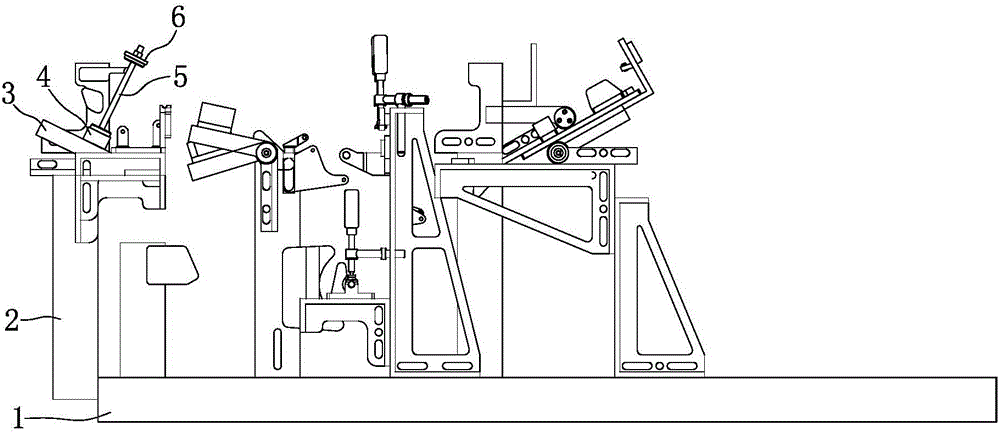

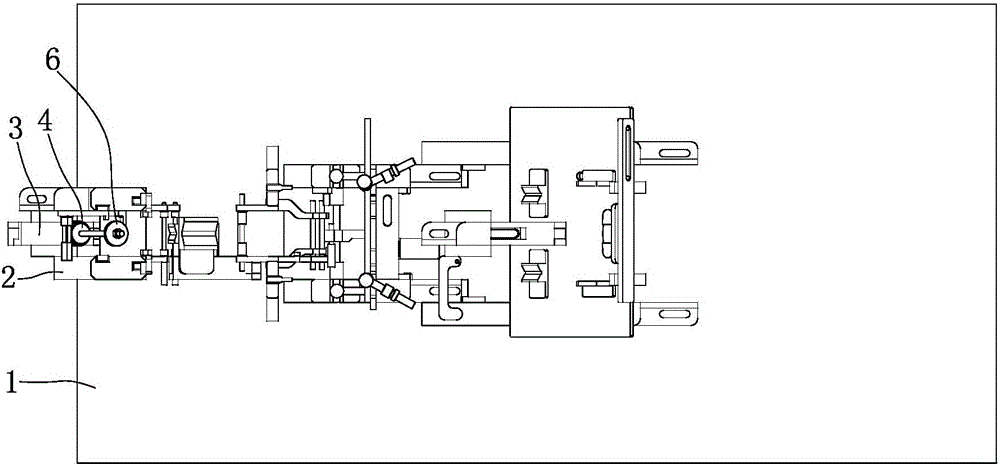

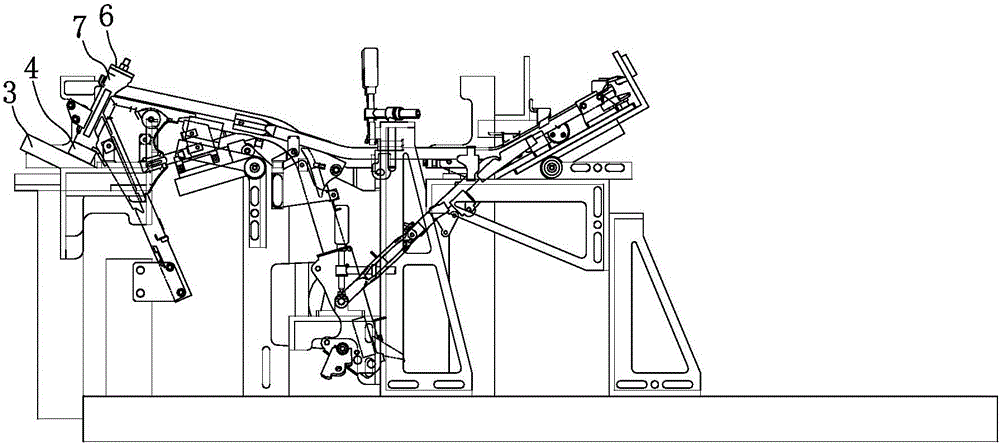

[0020] Such as figure 1 , figure 2 As shown, the working platform 1 is rectangular, and matching holes are arranged in a matrix on the top surface of the working platform 1 , and matching holes are evenly arranged on the peripheral side of the working platform 1 . The front end of work platform 1 is provided with front box 2, and the cross-section of this front box 2 is " U " shape, and the left and right sides of front box 2, the top surface and the back are evenly provided with matching holes. The back of the lower end of the front case 2 abuts against the front end of the work platform 1, and the front case 2 and the work platform 1 are connected by bolts.

[0021] Such as figure 1 , figure 2 As shown, an angler 3 is set on the top of the front box 2, and the angler 3 is composed of a fixed arm and a movable arm hinged to each other, and uniformly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com