Chambering method for spherical aluminum oxide particles

A spherical alumina and particle technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of limited hole expansion, carbon deposition, and difficulty in uniform dispersion of hole expanding agents, and achieve good hole expansion effect and good dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

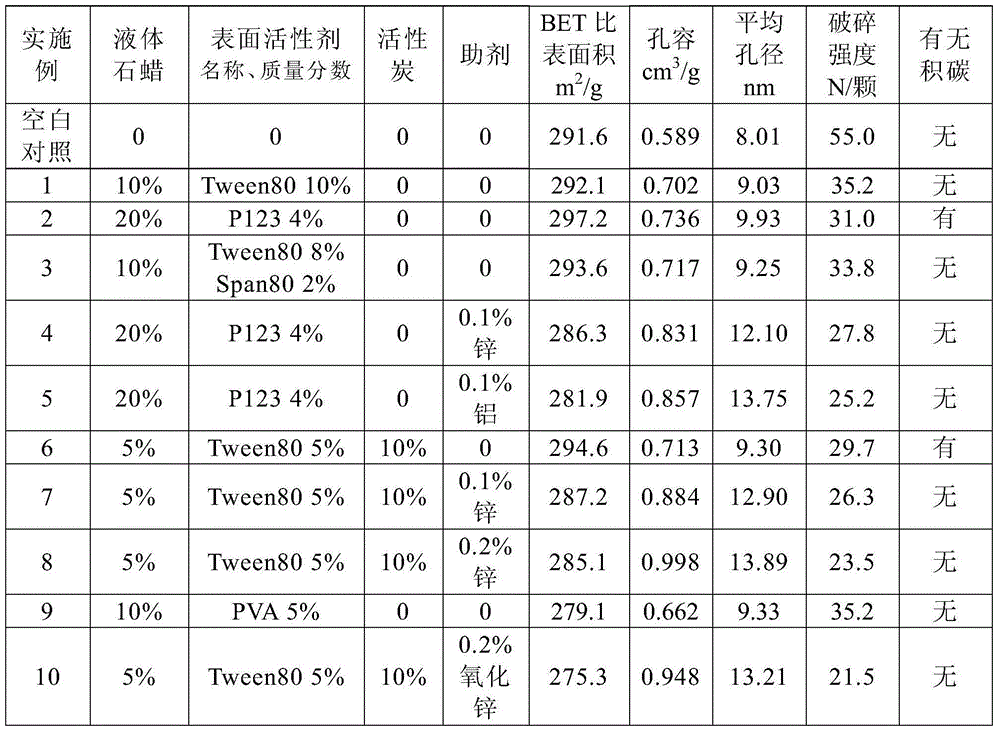

[0018] Get 50g pseudo-boehmite, add 100ml water to disperse, obtain pseudo-boehmite suspension; add 10% liquid paraffin in pseudo-boehmite suspension (take the pseudo-boehmite quality as 100%) , 10% Tween80 (100% of pseudo-boehmite quality), homogeneously emulsified to form emulsified suspension. Add 100ml of 1.5% alginate solution to the emulsified suspension and mix well to obtain an alginate-emulsified suspension; drop the alginate-emulsified suspension into 0.2M calcium nitrate to form a wrapped emulsified suspension Liquid alginate particles; washed with water, treated at 70°C and 70% humidity for 4 hours, dried at 70°C to constant weight, and calcined at 550°C for 8 hours to obtain spherical alumina particles. The properties of the pellets are listed in Table 1.

Embodiment 2

[0020] Get 100g pseudo-boehmite, add 200ml water dispersion, obtain pseudo-boehmite suspension; add 20% liquid paraffin (taking pseudo-boehmite quality as 100%) in pseudo-boehmite suspension, 4% P123, homogeneously emulsified to form an emulsified suspension. Add 50ml of 4.0% alginate solution to the emulsified suspension and mix well to obtain an alginate-emulsified suspension; drop the alginate-emulsified suspension into 0.8M calcium nitrate to form a wrapped emulsified suspension Liquid alginate particles; washed with water, treated at 70°C and 70% humidity for 4 hours, dried at 70°C to constant weight, and calcined at 550°C for 8 hours to obtain spherical alumina particles. The properties of the pellets are listed in Table 1.

Embodiment 3

[0022] The surfactant in the preparation process of the emulsified suspension in Example 1 was changed to 8% Tween 80 and 2% Span 80, and the prepared alginate-emulsified suspension was dropped into 0.2M aluminum nitrate to form The alginate granules that wrap the emulsified suspension, the rest are the same as in Example 1. The properties of the pellets are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com