Buried type side slope drainage system and construction method thereof

A drainage system, buried technology, used in excavation, infrastructure engineering, construction, etc., can solve the problems of collapse and damage of drainage ditch, troublesome waste cleaning, insufficient drainage and other problems, to avoid damage, reduce construction costs, durable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

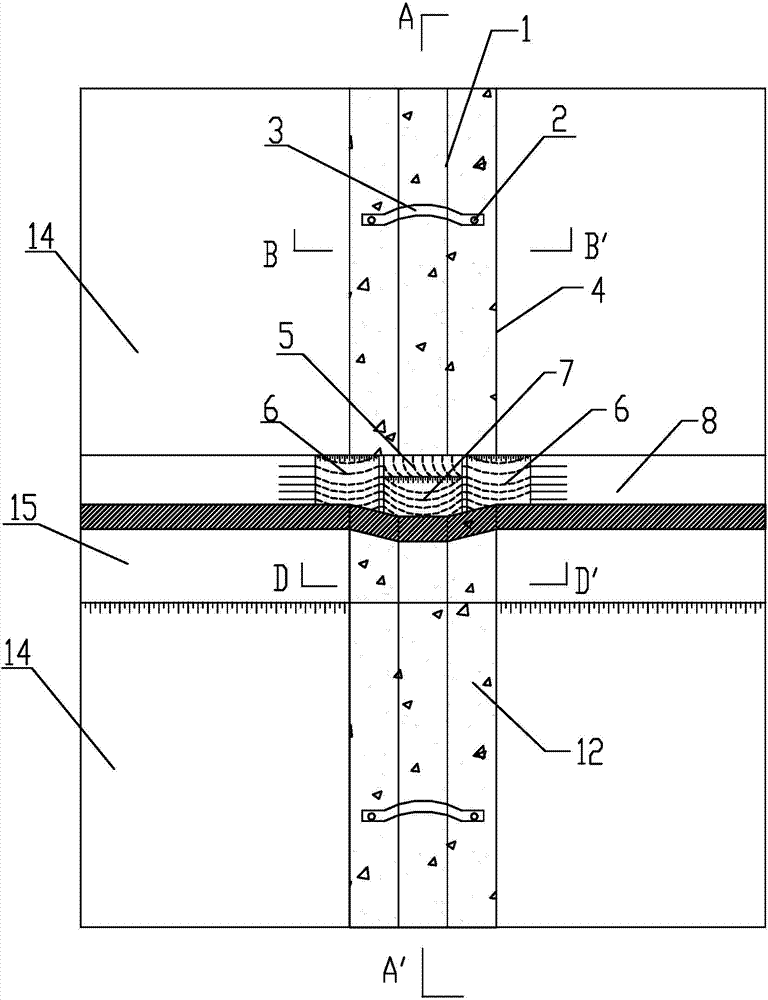

[0044] Example 1: Construction is carried out specifically for a certain filling slope. The slope is filled with geogrid reverse-wrapped woven bags layered and crushed gravel soil, and the slope is protected by spraying with hanging nets; the traditional drainage ditch is in the The masonry on the woven bag is easy to be damaged; this problem can be overcome by adopting the method of the present invention, and its specific construction steps are as follows:

[0045] 1. Measurement and setting out: Determine the setting positions of vertical drainage ditches and horizontal drainage ditches on the slope and platform of the fill slope according to the design drawings, and calibrate the axis positions of horizontal and vertical drainage ditches according to the design;

[0046] 2. Reinforced soil construction: According to the construction process, lay geogrids and turn up the woven bags, then backfill gravel soil and carry out layered rolling. During the filling process, design ve...

Embodiment 2

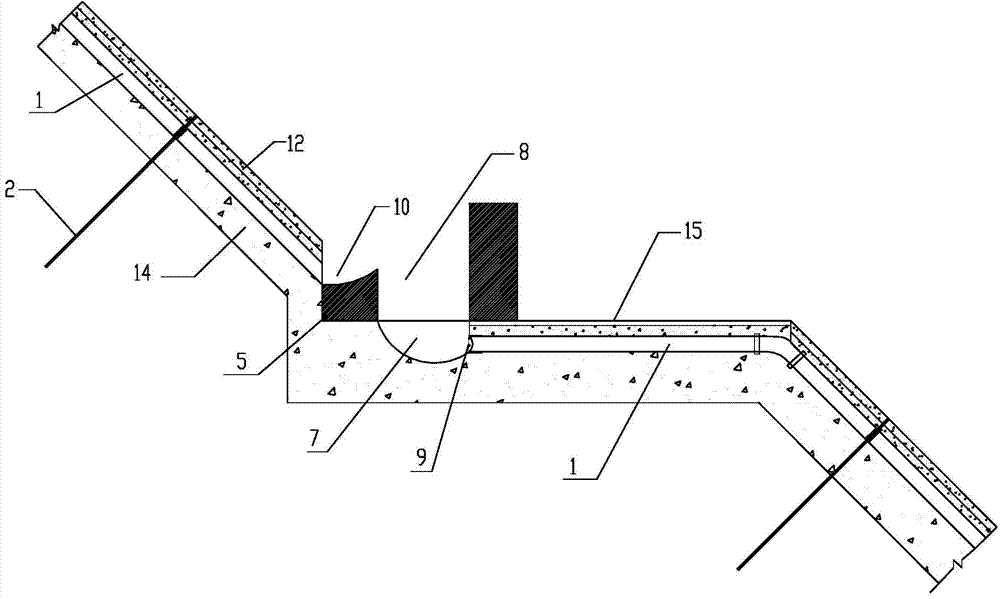

[0052] Embodiment 2: Take the excavation slope as a specific implementation. The slope is an excavation rock slope with moderately developed fissures. The slope is planned to be supported by anchor lattice beams. The use of traditional drainage ditches will destroy the continuity of the lattice beams and have a certain impact on the overall stability. This problem can be effectively solved by using this invention. The specific construction steps as follows:

[0053] 1. Slope shaping: trim the slope according to the design to form an excavated rock slope;

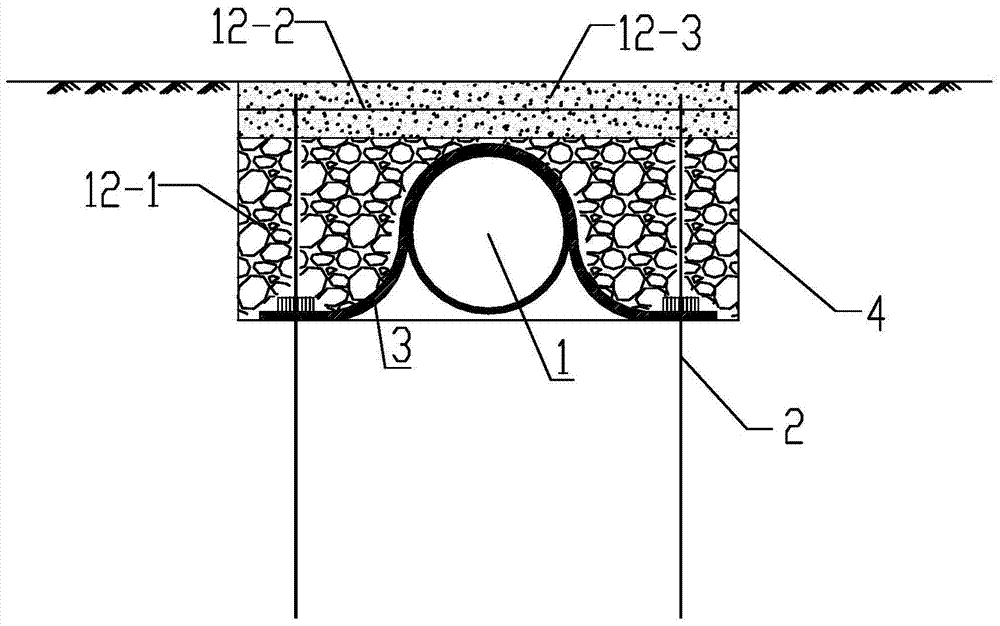

[0054] 2. Groove positioning and excavation: Position the horizontal and vertical drainage ditches according to the design standards, and then excavate at the position of the vertical drainage ditches to form a ditch-shaped drainage pipe pre-buried whose width and depth meet the design requirements of slope drainage groove;

[0055] 3. Lay anchor bolts: lay anchor bolts near the two sides in the pre-buried groove of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com