Device used for weakening stick-slip vibration of downhole drilling tool and control method of device

A stick-slip vibration, bottom hole drilling tool technology, applied in drilling tools, drill bits, drilling equipment, etc., can solve the problems of increasing drilling construction cost, affecting the ROP, affecting the life of the drill bit, etc., and shortening the time required for construction. The effect of reducing security risks and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

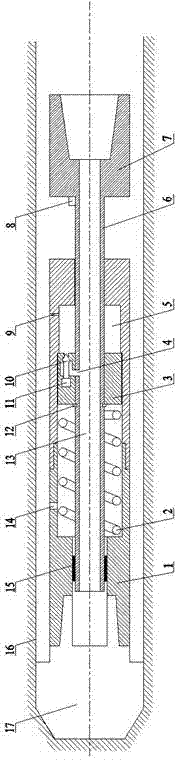

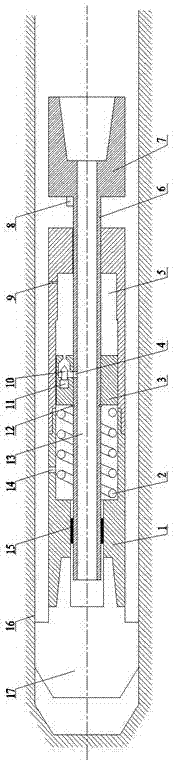

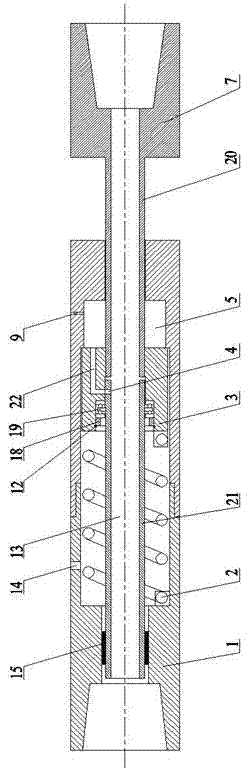

[0010] The present invention is a device for weakening the stick-slip vibration of the bottom hole drilling tool and its control method. There are two specific ways of implementation. figure 1 And attached figure 2 For the first specific implementation mode, image 3 It is the second specific implementation manner.

[0011] For the first specific implementation mode, refer to the attached figure 1 , 2 As shown, the present invention is a device for weakening the stick-slip vibration of the bottom hole drilling tool and its control method. The feature is: the present invention has an outer sleeve 1, and the outer sleeve 1 is equipped with a piston 3 and an automatic valve switch 11 to control the volume of the sleeve cylinder 5 so as to drive the outer sleeve 1 to move axially relative to the hollow shaft 6. The outer sleeve 1 and the hollow shaft 6 are connected by a spline 15, the upper end of the hollow shaft 6 is equipped with a strain sensor 8, the sleeve cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com