Mechanical leg imitating ostrich hind limb

A technology of mechanical legs and hind limbs, applied in the field of bionic robots, can solve problems such as low energy utilization, failure to operate normally, damage to machine parts, etc., and achieve the effects of improving energy utilization, improving energy utilization efficiency, and reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

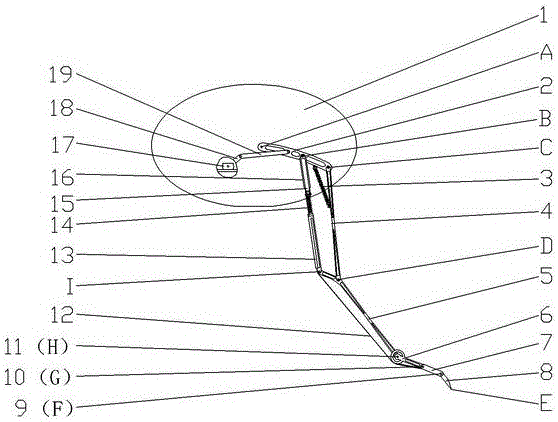

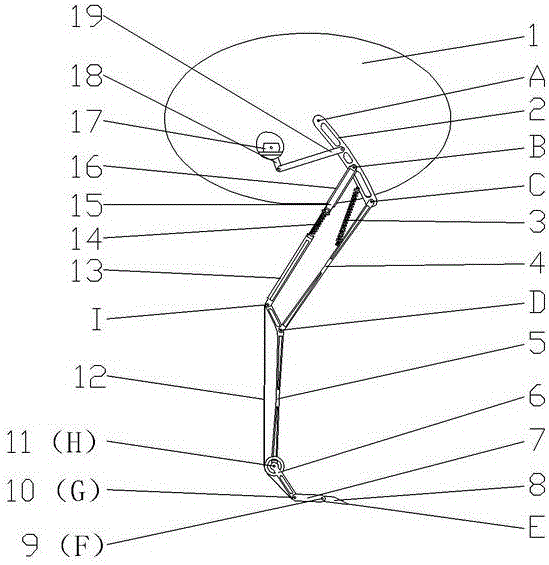

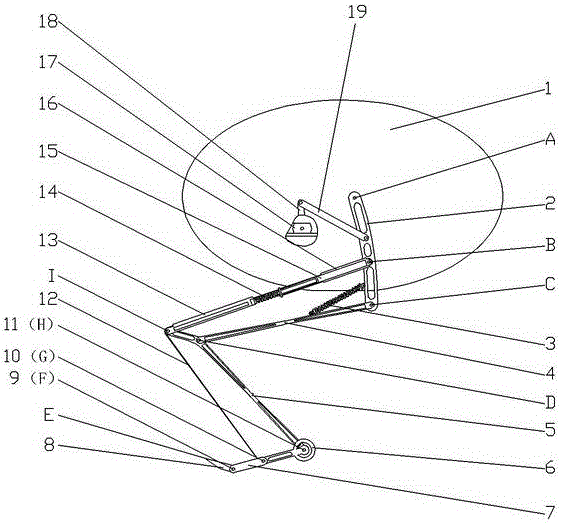

[0019] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a fuselage 1, a hip joint kinematic mechanism, a knee joint kinematic mechanism and an ankle joint kinematic mechanism;

[0020] The hip joint kinematic mechanism is fixed on the fuselage 1, the hip joint kinematic mechanism drives the knee joint kinematic mechanism to move, the knee joint kinematic mechanism drives the ankle joint kinematic mechanism to move; the hip joint kinematic mechanism is composed of a motor 17 and a crank rocker mechanism, wherein The crank-rocker mechanism includes a crank 18, a femur 2 and a connecting rod 19; a motor 17 is mounted on the body 1, and the motor 17 drives the crank 18 to rotate clockwise, and the motor 17 converts the rotation of the crank 18 into the femur 2 through the crank-rocker mechanism. Continuous swing;

[0021] Described knee joint motion mechanism comprises femur 2, first spring 3, tibia 4, metatarsal bone 5, brake wire 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com